Apeks Supercritical The Duplex™ Operation Manual

23

Revision Date 8/28/2018

3. System Operation

3.1. Before the Cycle

3.1.1. Loading and Closing Extractor

3.1.1.1. CAUTION: Extractor flange can weigh up to 50lbs and care should be given to avoid

damage and injury.

3.1.1.2. NOTE: Use appropriate tools to open and close vessels. Only use a rubber mallet on the

extractor vessel hammer unions.

3.1.1.3. Before loading the extractor visually inspect the metal filters on either end of the vessel

for any signs of clogs or damage.

3.1.1.4. Use the supplied metal funnel to help load the extraction vessel. Vessels should be

loaded in stages using gentle packing in between to increase the amount of material able

to be loaded into the vessel.

3.1.1.4.1. Typically, botanicals perform best in CO

2

extractions when ground as fine as

possible down to a particle size of 200 µin or roughly the consistency of coffee

grounds.

3.1.1.4.2. Any amount of material can be loaded into the Extraction Vessel – the vessel does

not have to be full in order to operate correctly.

3.1.1.5. After loading is complete, ensure all sealing surfaces are clean and free of debris. This

includes the top of the extraction vessel, the cup seal groove, the threads and the face of

the plug around the metal filter.

3.1.1.5.1. If threads need cleaning (e.g. get contaminated with raw material), remove all anti-

seize lubricant from threads on both the vessel and the nut.

3.1.1.5.2. Once all old material is removed, reapply thin new layer of the food grade anti-seize.

(acceptable anti-seize is included in initial system packaging and can be bought from

the online store, see references)

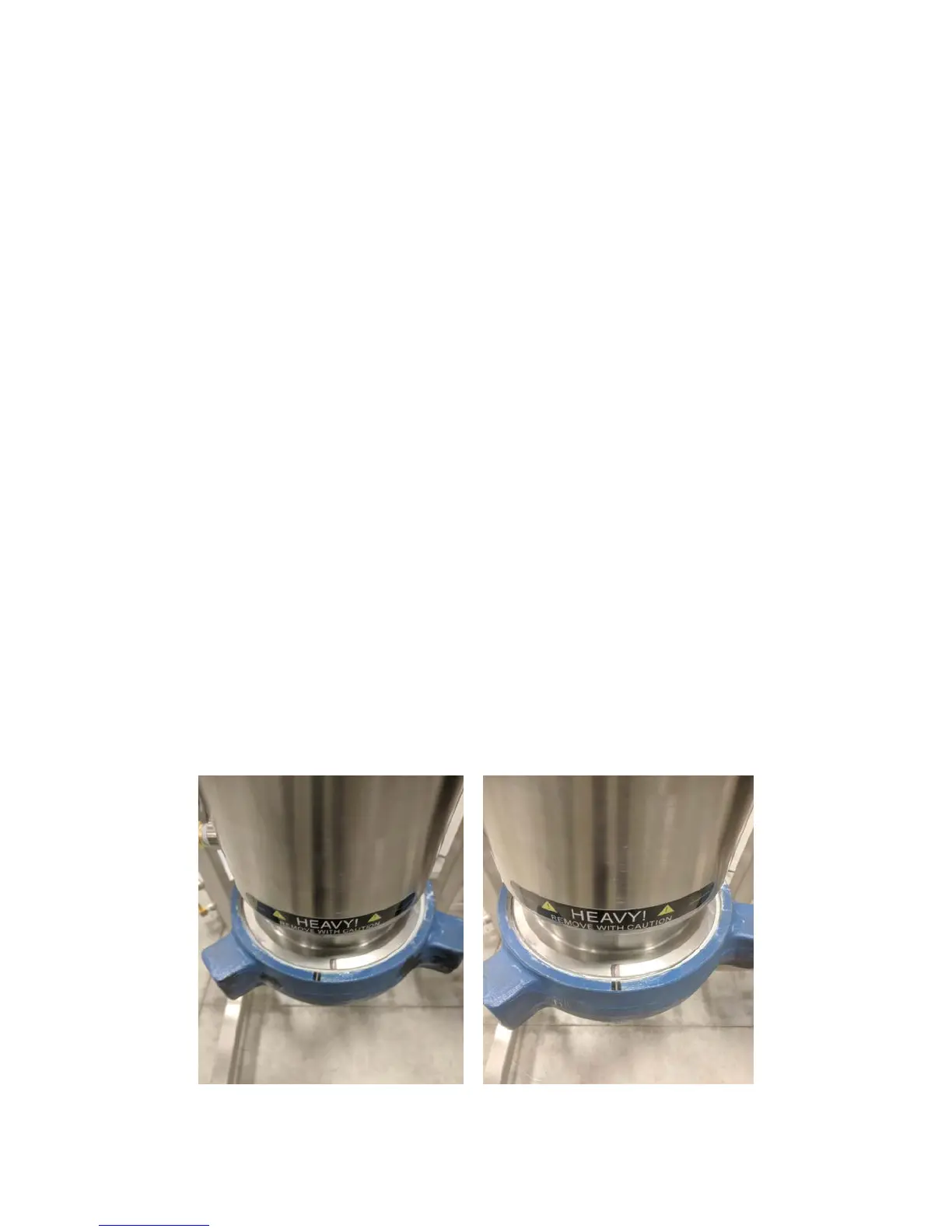

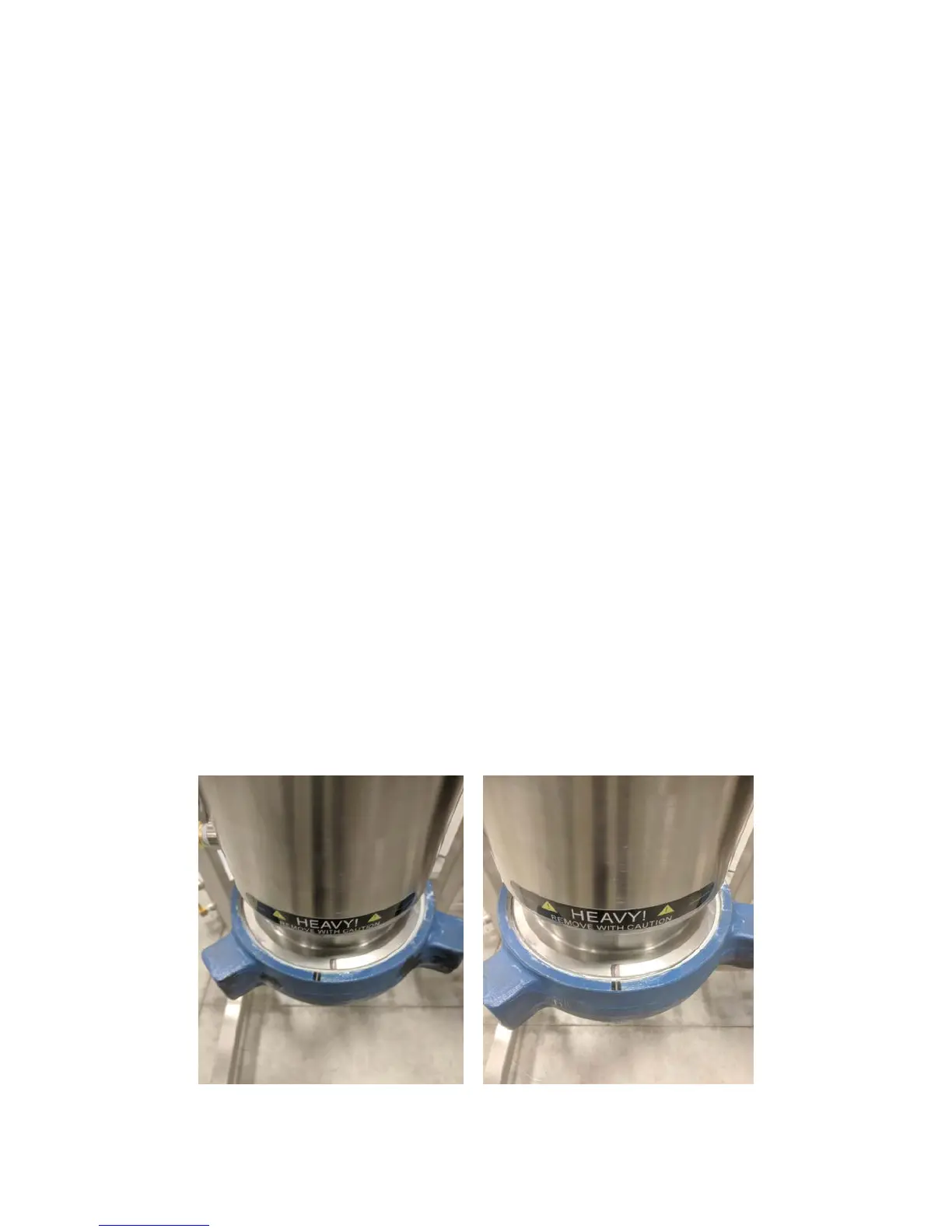

3.1.1.6. Thread on the hammer union. Use supplied rubber mallet to fully close vessel 3 to 5 hits

past hand tight. Both the nut and the vessel are marked with a closure mark (air etched

line). These two lines should be no more than an eighth inch apart. Nuts should close to

approximately the same location each time. If it does not then there may be debris in the

threads that needs cleaned out.

NOT CLOSED CLOSED

Loading...

Loading...