6.5 Sample test

6.5.1. Rinse conductivity electrode in pure water, allow it to dry, and submerge it in the sample solution.

Stir the solution briefly and allow it to stay in the sample solution until a stable reading is reached and

icon appears on LCD, then get the reading value, which is the conductivity value of the solution.

6.5.2. Press key to switch to TDS.

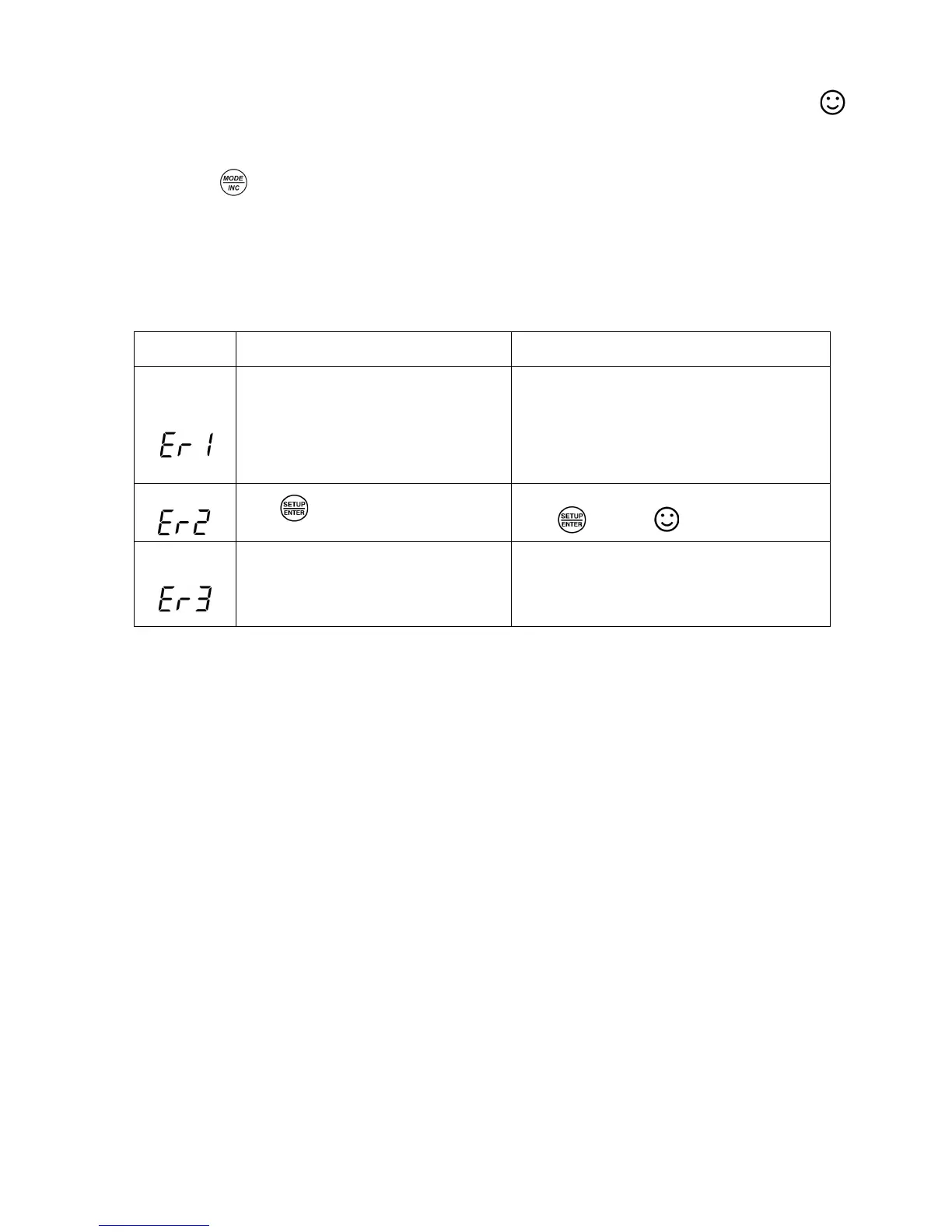

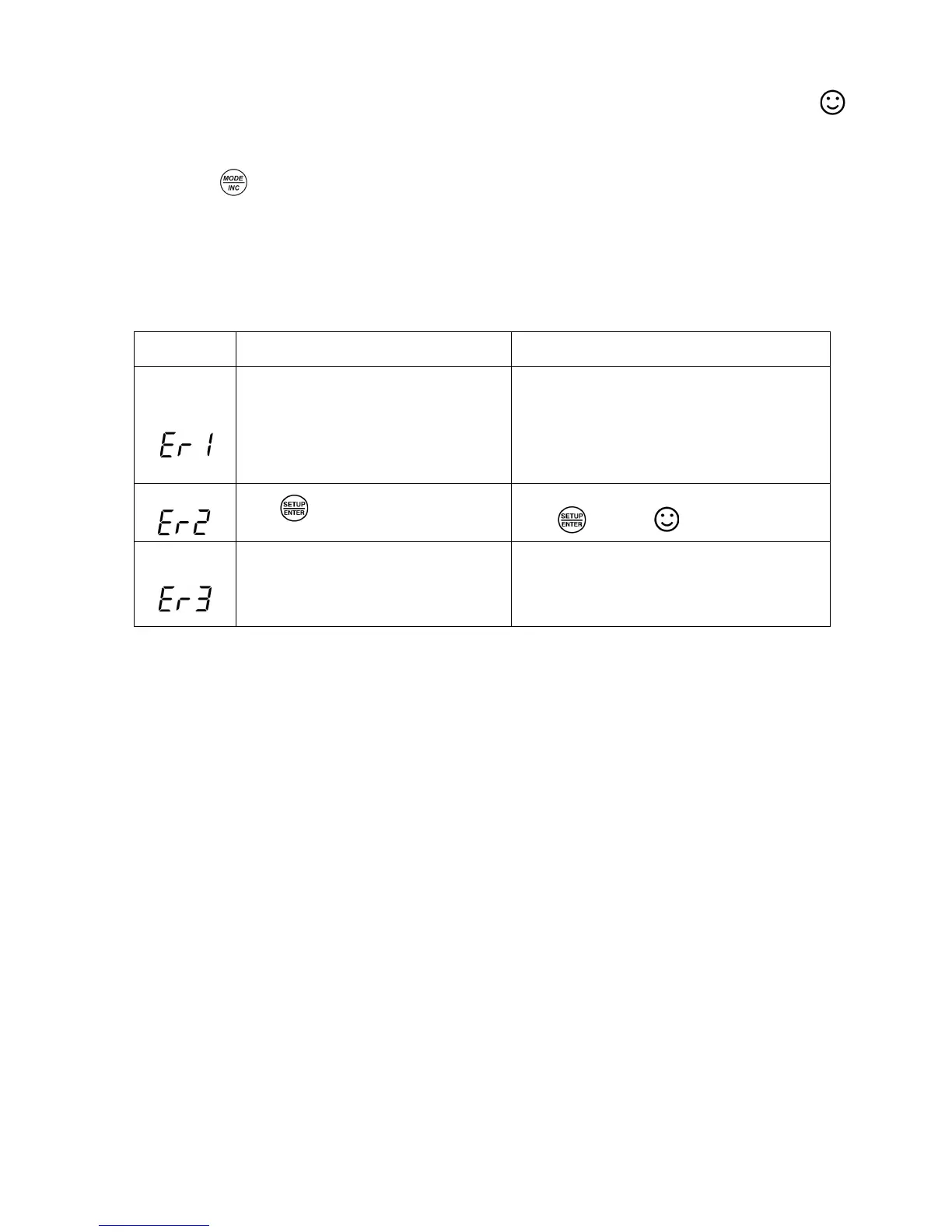

6.5.3. During the process of calibration and measurement, the meter has self-diagnosis functions,

indicating the relative information as below: chart – 11.

Chart – 11 Self-diagnosis information of conductivity measurement mode

6.5.4 Factory default setting

For factory default setting, please refer to parameter setting P2.5 (Item 7.4). With this function, all calibration

data is deleted and the meter restores to the theory value. Some functions restore to the original value

(refer to appendix -1). When calibration or measurement fails, please restore the meter to factory default

setting and then perform re-calibration or measurement. Please note once set the factory default, all the

data deleted will be irretrievable.

6.6. Conductivity electrode maintenance

6.6.1. Always keep the conductivity electrode clean. Before taking a measurement, rinse the electrode in

pure water. It is recommended to rinse it again in the sample solution. When submerge the electrode in

solution, stir the solution briefly to eliminate air bubbles and allow it to stay until a stable reading is reached.

For conductivity electrode which is drily stored, soak the electrode in pure water for 5-10 minutes. Rinse

the electrode in pure water after measurement.

6.6.2. The interaction rod of Model 2301T-S conductivity electrode is coated with platinum black to minimize

electrode polarization and expand measuring range. The platinum black coating adopted our special

processing technology which improves the electrode performance and the firmness of the coating. If the

platinum black electrode is stained, gently clean the electrode with soft brush in warm water containing

detergent or alcohol.

Loading...

Loading...