- that the lubricant used is of an APV recommended type

- that the pump shaft (38) and the motor shaft are properly

aligned.

- that the pump port connections are tight.

- that there is liquid in the pump.

- that the pump rotates freely.

- that all suction and discharge valves are open.

- that nothing obstructs the flow and that liquid has free access to

the pump.

- that the rotational direction is correct.

- that the coupling guard has been fitted properly.

- if the pump has a flushed seal, check that the flushing flowrate is

adequate. See “Accessories Manual 8.1, Shaft seal”.

- that the pump is free from dirt, weld spatter or other foreign

objects. See section 3.1.

NOTE:

Synthetic and mineral lubricants must not be mixed.

3.3 Immediately after starting the pump:

1. Listen for unusual noises.

2. Look for leaks.

3. Check that there is a flow.

3. Before start-up and starting the pump

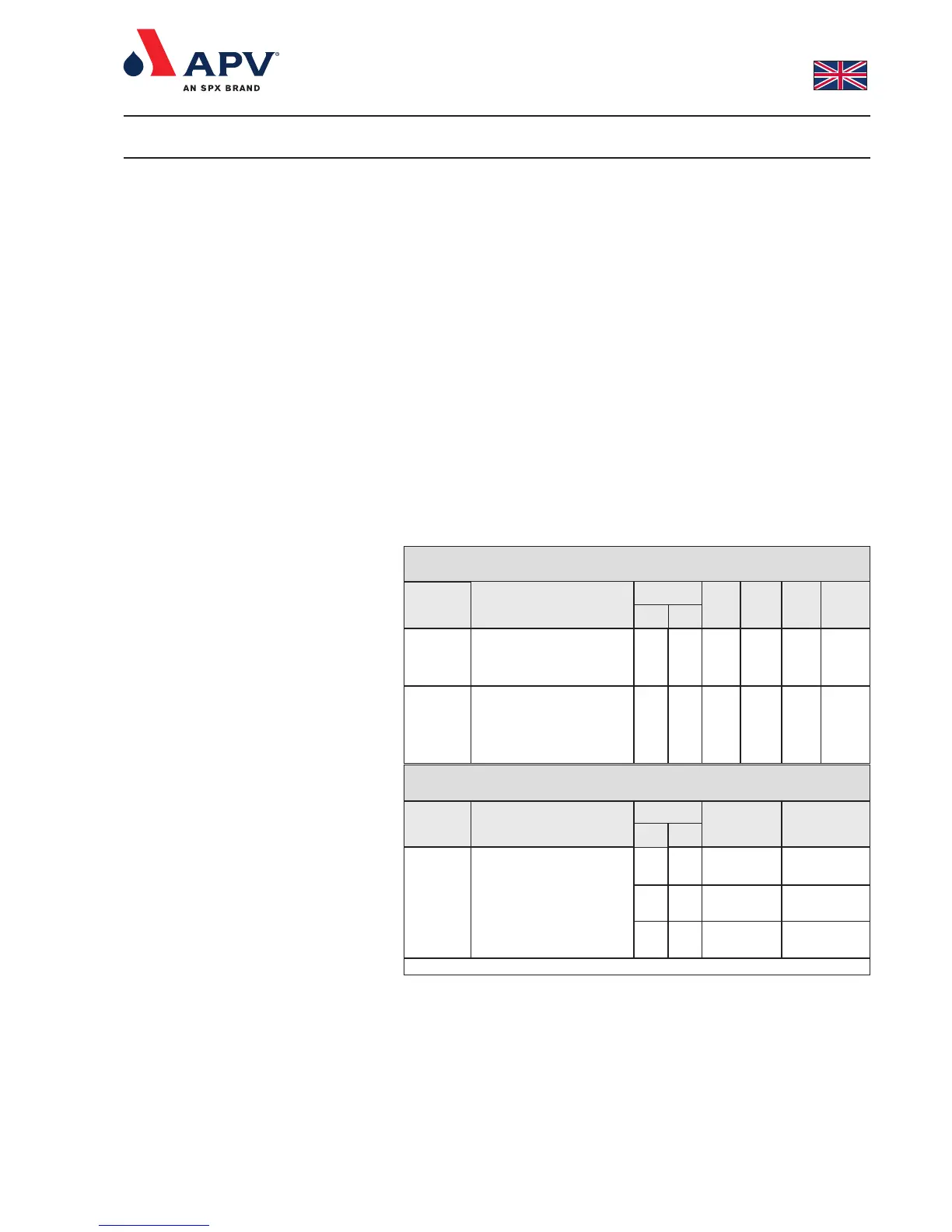

-20- +120 °C

Ambient temp. t<40 °C

and

all DW pumps with product

temp.<110 °C

Energol

GR-XP

220

X

Mineral

Oil temp.

°C

Mobil

gear

630

Omala

Oil-

220

Alpha

SP

220

120-+180 °C

Ambient temp. t>40 °C

and

all DW pumps with product

temp.>110 °C

At oil temperatures higher than

120ºC, another drain plug and oil

level gauge must be used.

Enersyn

SG-XP

220

X

Mobil

Glygole

HE460

Tivela

Oil WB

Alphasyn

T220

Castrol

Synthetic

Lubricant

type

Pump/ambient

temp. °C

BP Mobil Shell

Mineral

Approval

Mobil:

DTE FM 220

USDA (H1)

Oil temp.

°C

X

Ambient temp. t<40 °C

and

all DW pumps with product

temp.<110 °C

X

FDA 178.3570

178.362

USDA (H1)a

USDA (H1)

Castrol:

Vitalube GS 220

Synthetic

-20- +120 °C

Lubricant

type

Pump/ambient

temp. °C

Type

Special lubricants for food and pharmaceutical industries:

Standard Lubricants:

X

Klüber:

Klüberoil 4UH- 220

APV recommends that the oil be changed every year.

Loading...

Loading...