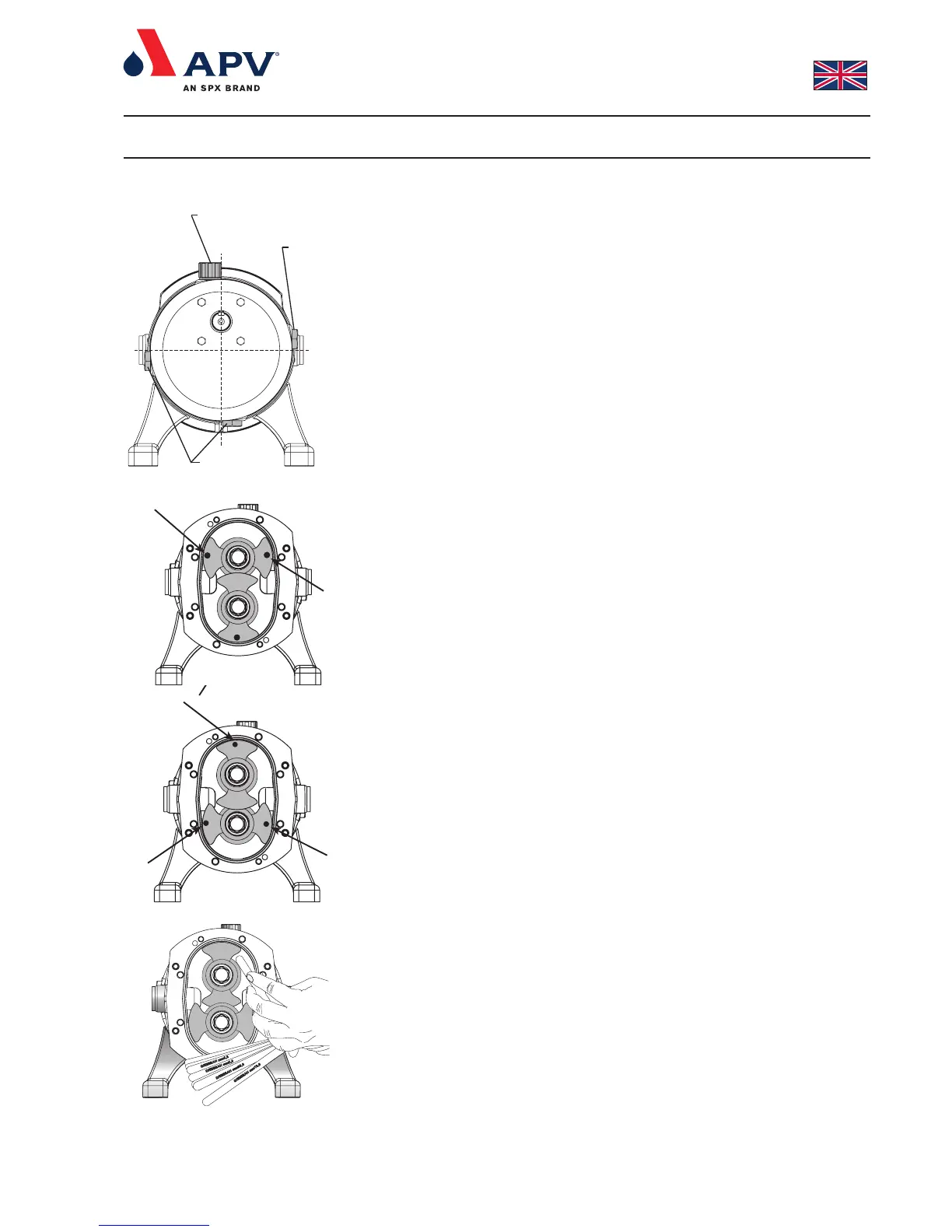

If the position of the feet and hence in- and outlet is changed, it

is necessary to change the position of the oil filler plug, the oil

level window etc. as shown in fig. 19.

NOTE:

Mount the plug (14) flush with the surface. Use Loctite 242.

4.9 Adjustment of the rotors axial position

To be able to operate the pump effectively and safely, it is necessary

to carry out the adjustment of the rotors axial position after having

dismantled and re-assembled the pump to ensure the correct axial

position of the two rotors. Use the sectional drawing for reference

(page 2).

The measured clearance should be as close to the clearances

described in section 6.8 as possible.

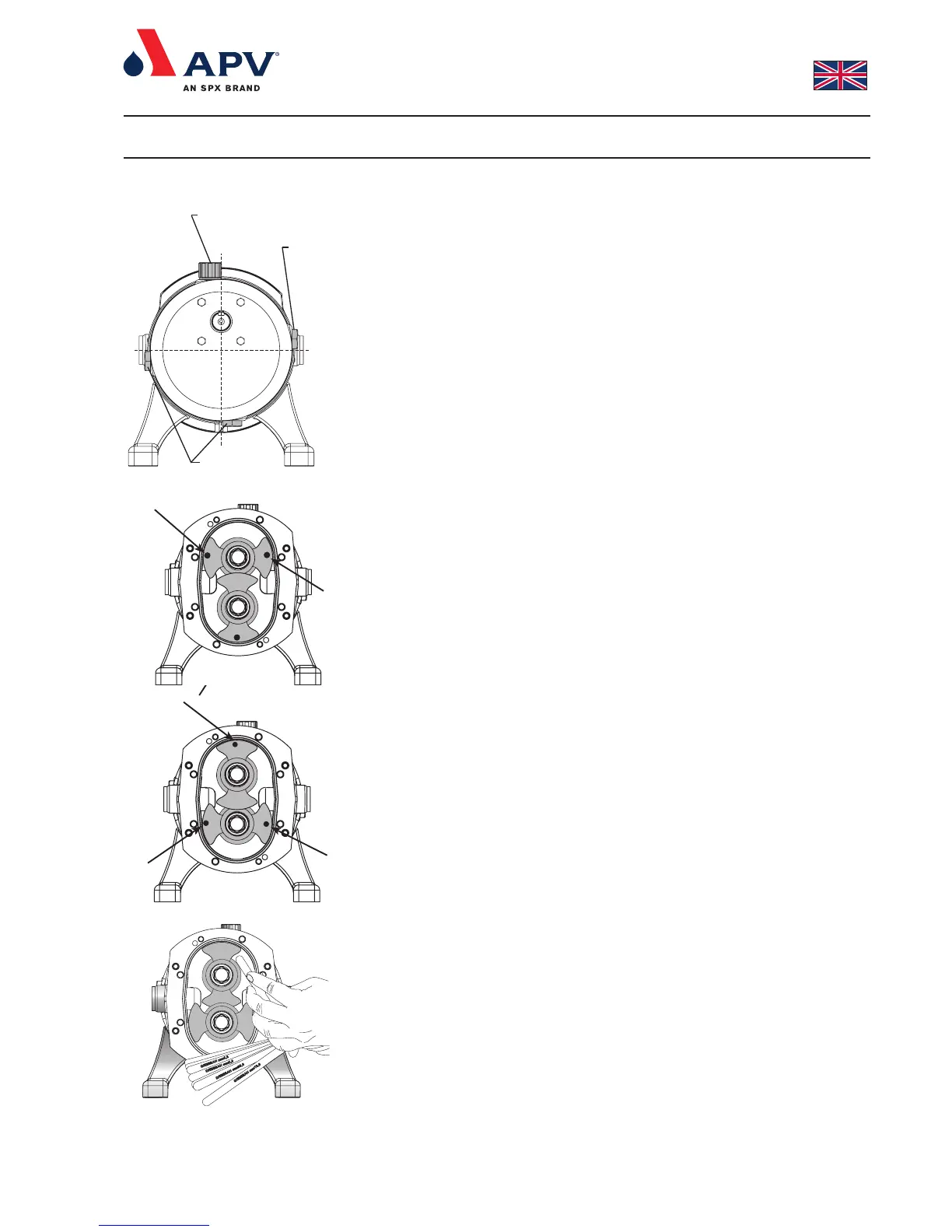

1. Measure the difference in depth between rotors (35) and rotor

case (9) by means of a depth micrometer. The points at which

you should measure the depths are shown in fig. 12 and 13.

Then the rotors are turned 180° and measured again. So that

twelve measurements are made in total.

2. Measure the rear clearance by means of feeler gauges. See fig.

14. Never go below the min. clearance stated in section 6.8. The

rear clearance should be measured at the same points as stated

in section 4.9 item 1.

3. Measure the radial clearance between rotor (35) and rotor casing

(9) by means of feeler gauges. The clearance should be

measured at the same rotor positions as stated in section 4.9

item 1.

4. If the clearances are not within the limits stated in section 6.8 or

if the distances measured able to be made closer to the mean

values stated in section 6.8, the rotors (35) are removed as

stated in section 4.2.

5. Remove the O-rings (36) situated on the shafts (38,39).

6. Remove the shims (37) of the shaft (38,39), measure the total

thickness of the shims with a micrometer, and add or subtract the

required amount of clearance to the shim thickness (e.g. if front

clearance is 0.1 mm too large, 0.1 mm must be added to the

total thickness of shims).

7. Refit shims (37) to the shafts (38,39). The thinner shims must be

inserted first.

8. Refit O-rings (36) on the shafts.

9. Refit rotors (35) as described in section 4.2.1.

10. Measure front and rear clearance again. If the clearances are

still outside the limits, or if they can come closer to the mean

values stated in section 6.8, repeat shimming procedure until the

measured clearances are correct.

11. When the front and rear clearances are correct, check that the

rotors (35) turn freely.

4. Dismantling and re-assembling the pump

Fig. 13

Fig. 14

Fig. 12

Oliedrænprop /

Fig. 19

Oliepåfyldningsstuds /

Oil filler plug

Olieskueglas /

Oil level window

Loading...

Loading...