3. Before start-up and starting the pump

3.4 Fault Finding

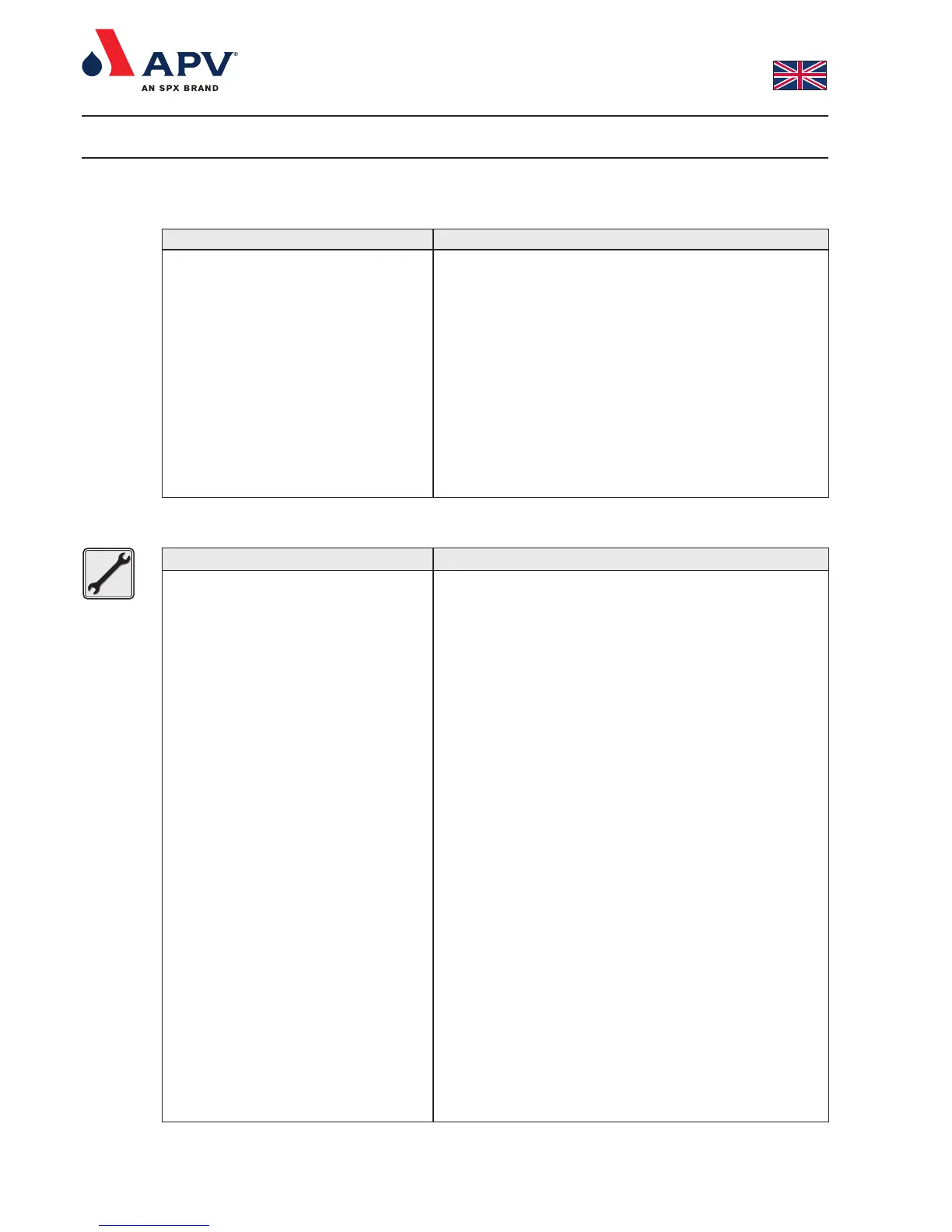

Motor overheats:

Pump under capacity:

No flow from pump:

Unsteady flow:

Noise and vibration:

Stall on start-up:

Pump overheating:

Excessive rotor wear:

Excessive power absorbed:

Pump seizure:

Shaft seal leskage:

6, 7, 14, 15, 17, 19

2, 7, 8, 9

1, 2, 3, 5

2, 4, 5, 7

2, 4, 5, 6, 7, 9, 10, 13, 14, 15, 16, 17, 18, 19, 20

6, 7

7, 14, 15, 17, 19

4, 10, 13, 14, 15, 18, 19

6, 7

6, 10, 13, 14, 15, 18, 19

11, 12, 13

Possible causes, see: cause/possible remediesSymptoms

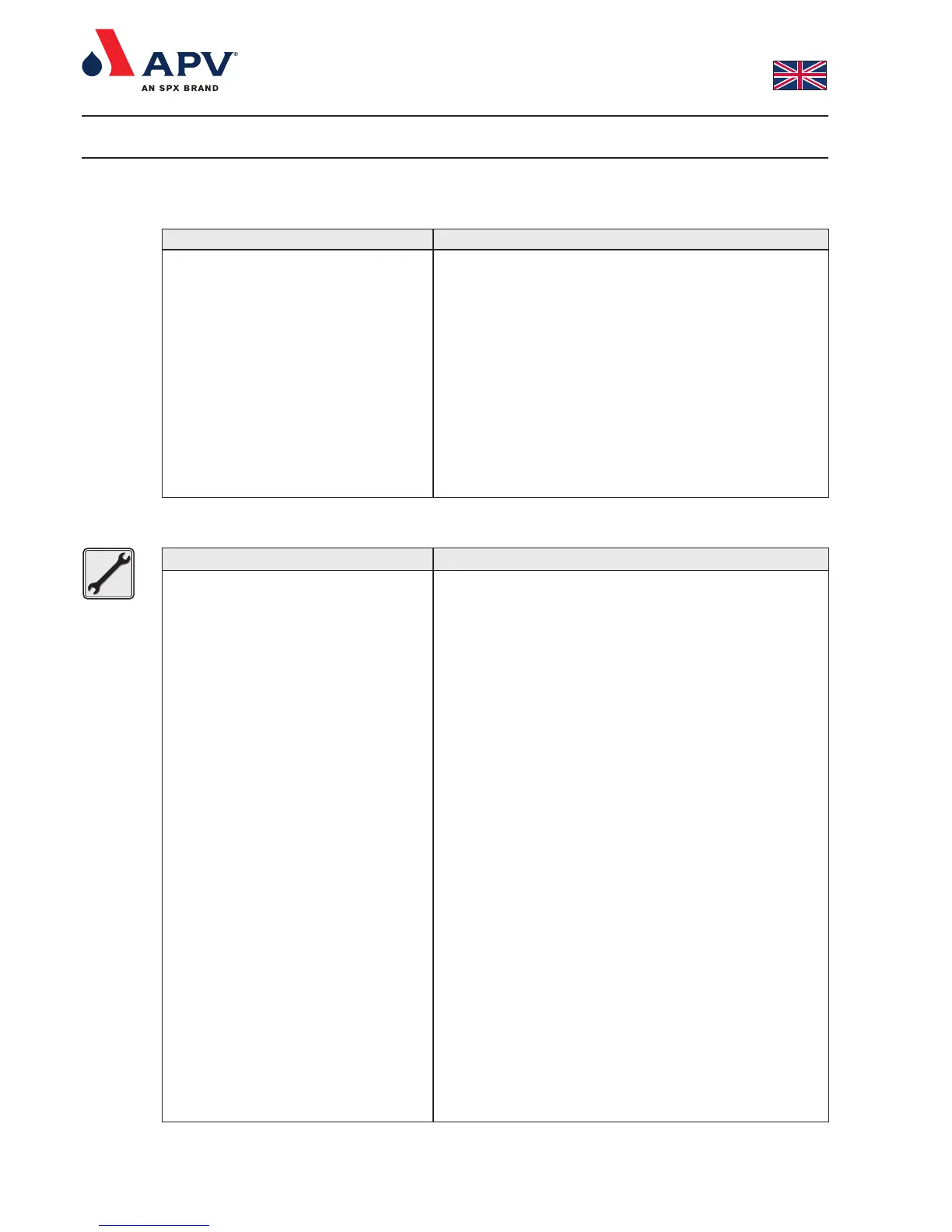

1. Incorrect rotation:

2. Insufficient N.P.S.H. and, as a result of

this, cavitation:

3. There is no liquid in the pump.

4. Air entering pump:

5. Blocked or restricted suction pipe:

6. Discharge pressure exceeds the allowable:

7. Product viscosity too high:

8. Product viscosity too low:

9. Worn rotors:

10. Shaft bearing wear:

11. Worn mechanical seal:

12. O-ring incompatible with product:

13. Worn timing gears:

14. Insufficient lubricating oil:

15. Incorrect grade of lubricating oil:

16. Rotor contact with rotor case or front

cover:

17. Pump and motor misalignment:

18. Foreign objects in product:

19. Loose bolts between pump, motor and

base frame:

20. Loose bolts between gearcase and foot:

Reverse direction of motor by interchanging 2 of the phaseleads.

Increase N.P.S.H., raise suction vessel, lower pump, reduce speed,

increase suction pipe diameter, simplify and shorten suction pipe run,

remove bends and other components which produce pressure loss.

Introduce liquid - vent air.

Check pump suction and system connections.

Check pipe system, clean any filter if necessary.

Check for obstruction, lower pressure by increasing pipework diameter.

Decrease speed - increase product temperature.

Increase speed - reduce product tempe rature - reduce clearance

between rotor, pump housing and front cover.

Renew

Replace bearing or return pump to APV for overhaul,if necessary.

Renew.

Check chemical compatibility chart, or contact APV for alternative

elastomers.

Replace gears and retime rotors.

Top up with correct grade of lubricant.

Check that the lubricant used is recommended by APV.

Drop discharge pressure, check clearances between rotors, front cover

and pump housing. Check that temperature shifts are as recommended in

section 6.4.

Correct alignment

Fit strainer.

Tighten bolts. Then check that pump and motor are lined up correctly.

Tighten bolts. Then check that pump and motor are lined up correctly.

Cause Possible remedies

Loading...

Loading...