26 Ultrasound Controller Manual

HELP

Select HELP to show information about connecting the Ultrasound Controller.

Level Sensor TROUBLESHOOTING

Display shows:

set - Settings is missing

cal - Calibration of air and/or liquid must to be done.

set - Some setting is missing.

err - Measurement cannot be done due to an error that was measured during calibration: Either

level sensor or velocity sensor echo is too weak or the velocity sensor echo with air is too

strong.

OVER - Measured level is between 100% and 170%.

The Echo strength, Thld and %Echo should be checked: If the echo is weak compared to threshold

there can be problem measuring the level. Make sure the echo is reflected properly back to the

level sensor. The bottom thickness and material also influences the echo strength, see Mounting

the Level Sensor.

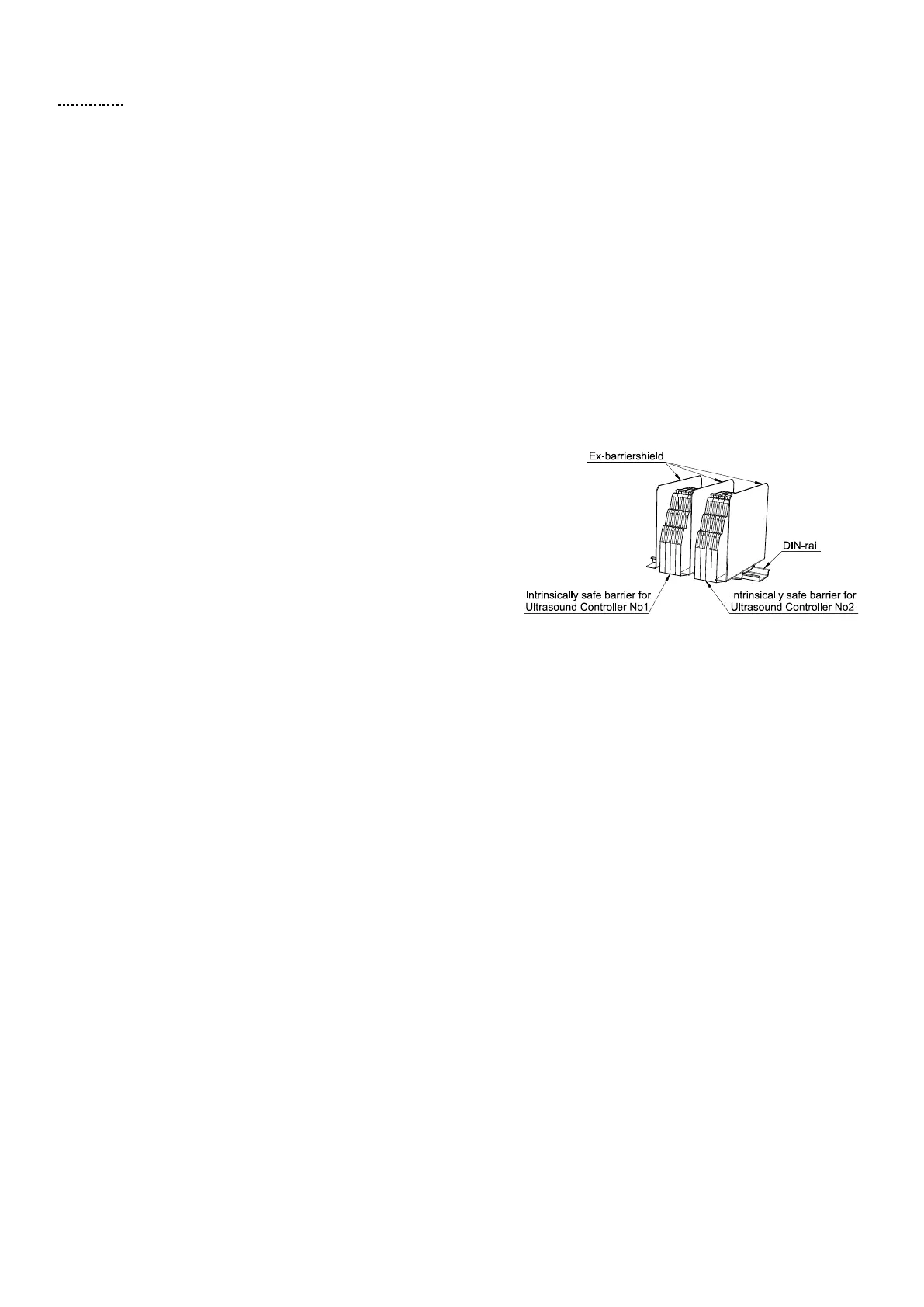

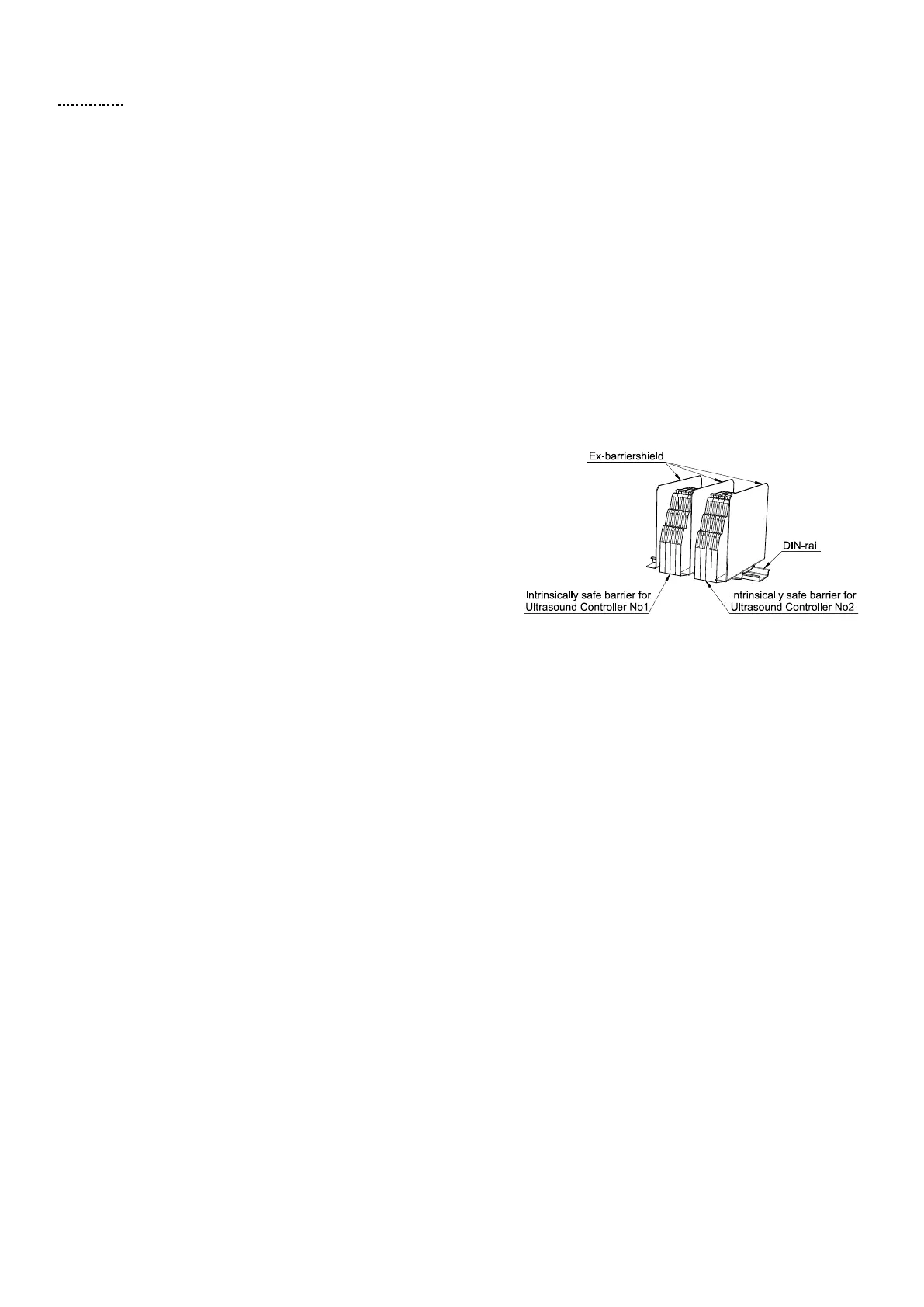

Electric interference can cause trouble because it can

increase the threshold. To minimize the risk of electric

interference it is important that sources of interference

like frequency inverters should use screened cables

for the motor. Also any unscreened part of the cable

between the Level Switches and Ultrasound Controller

should be short. If ex-barriers are used, Ex-

barriershields must be used.

In order for Ultrasound Controller to measure the level well it needs echoes from the surface. Due

to various reasons however the echoes can become too weak to be able to be detected. An

indication of how well the echoes are detected is %Echo, which is 100% with good echo but

becomes less with weak echo. Also echo strength dB and threshold Thld dB indicates how strong

the echo is compared to background noise. In an empty container there is no echo but %Echo

may still show more than 0% because noises are misinterpreted as echoes.

For reliable measurement strong echo is good. Some reasons for weak echo:

Container is empty. - This is ok there should be no echo then.

Bottom is thick. – If possible make bottom thinner. Also consider ideal thickness for resonance at

2 MHz.

Bottom thickness is such that resonance is not at 2MHz. – If it is possible make bottom thickness

so resonance is at 1,9 - 2,2 MHz (d = n * λ / 2 = n * v / 4000000 λ = wavelength at 2MHz d =

bottom thickness n = 1,2,3… v = sound velocity m/s) (stainless steel: d = n * 1,41mm).

Liquid level is very low. – The echo is veiled by echoes within the bottom. Measuring very low

level is difficult due to short echoes inside the bottom.

Bubbles or particles scatter the echo.

Level is outside the range (170%). – Set the range.

Container is full and the inside surface of the top of the container is shaped in such a way that

echoes are reflected in wrong direction. – Make a small portion of the inside surface flat just

above the level sensor.

Level sensor is aimed in wrong direction. – Aim the level sensor in the right direction.

Loading...

Loading...