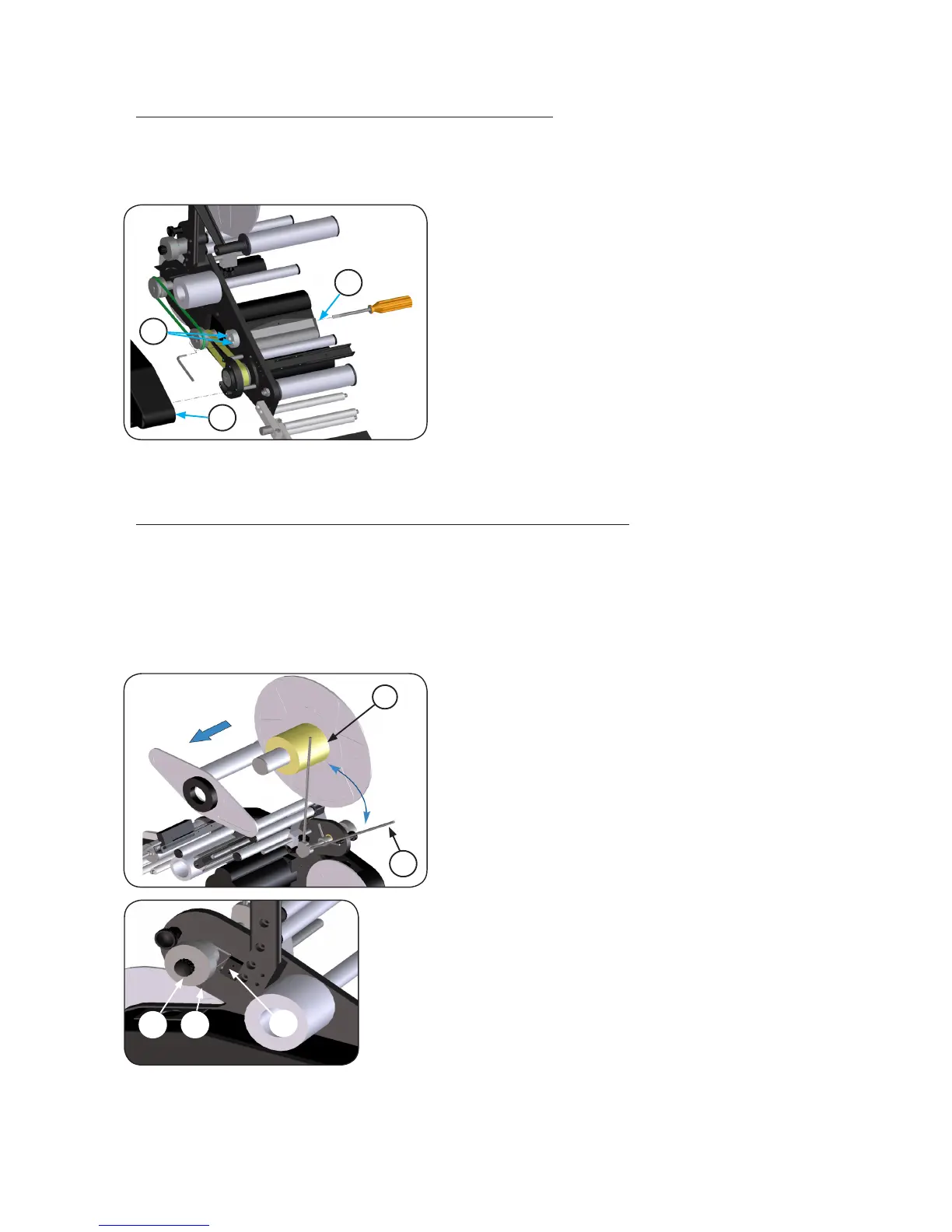

3.4. Adjustment of the transport roller pressure

In case of wrong feed of the labels (wrong application during the labelling) perform the following indications:

• disconnect the power supply and pneumatic if it foresees;

• remove the shed (3) loosing the screws;

• unhook the transport roller;

• unloose the cheese head screws (1) and rotate the eccentric

axis (2) adjusting the roller pressure;

• x the two cheese-head screws;

• reassemble the shed (3).

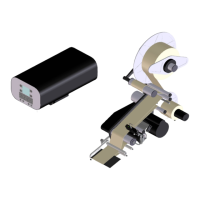

3.5. Adjustment of the mechanical sensor for end of roll

The end-of-roll device (optional), enables to warn the user when the label coil is approaching to the end

IThe device is essentially composed by an adjustable rod which (1), pushed by a spring, must follow the external

edge of the labels coil (2)

The adjustment of the bending for this rod, enables to adjust the minimum quantity of labels which signals to

the control unit the end-of-roll.

In order to adjust this device, perform the following operations:

• Set a label coil with few labels(2), (as much as it is necessary

to switch on the end of coil alarm)

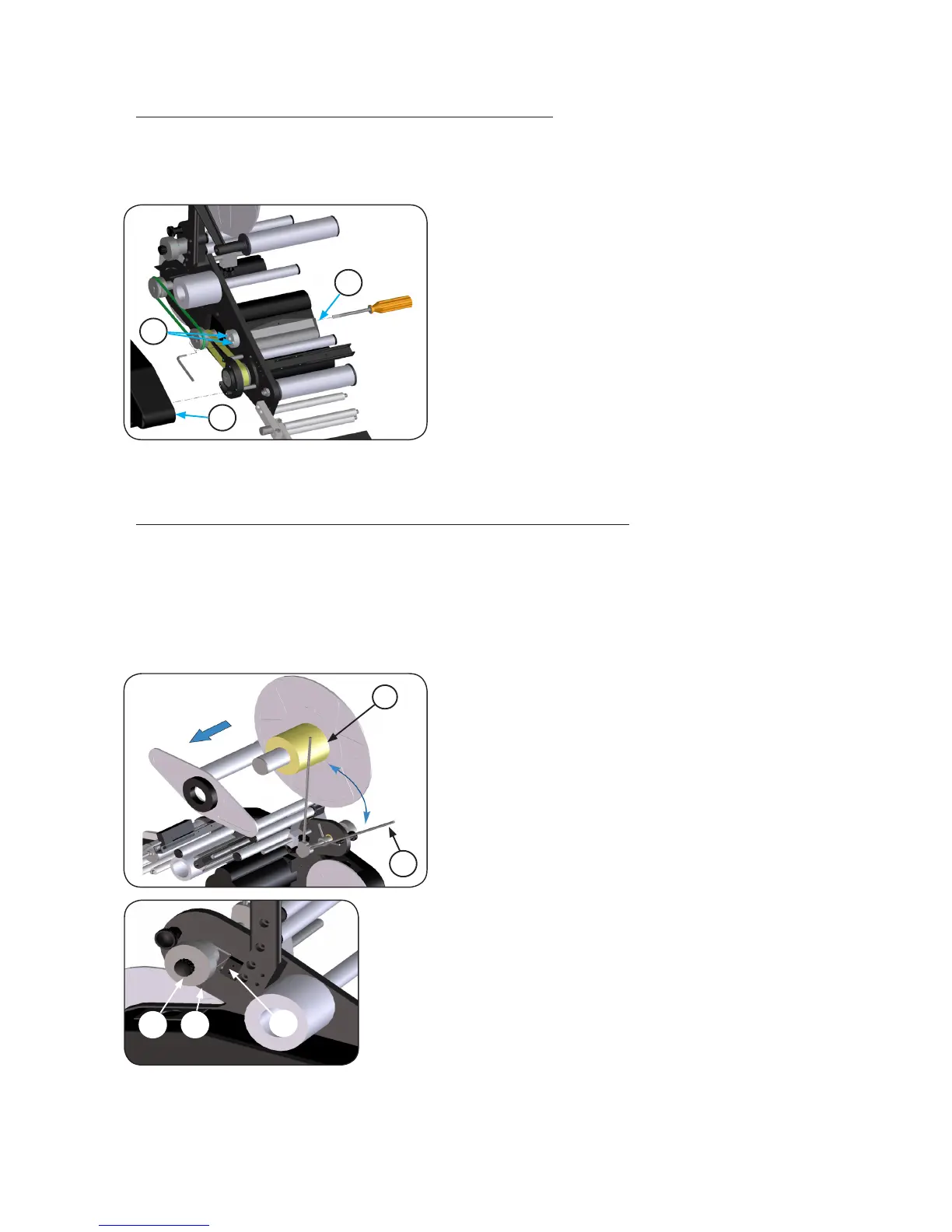

• Position the end-of-coil rod in reading position(1) (rod leaning

on the coil)

• Loosen the locking knob (3) and turn the ring nut (4) clockwi-

se or anticlockwise until you hear the microswitch tripping(5).

Tighten the locking knob.

Loading...

Loading...