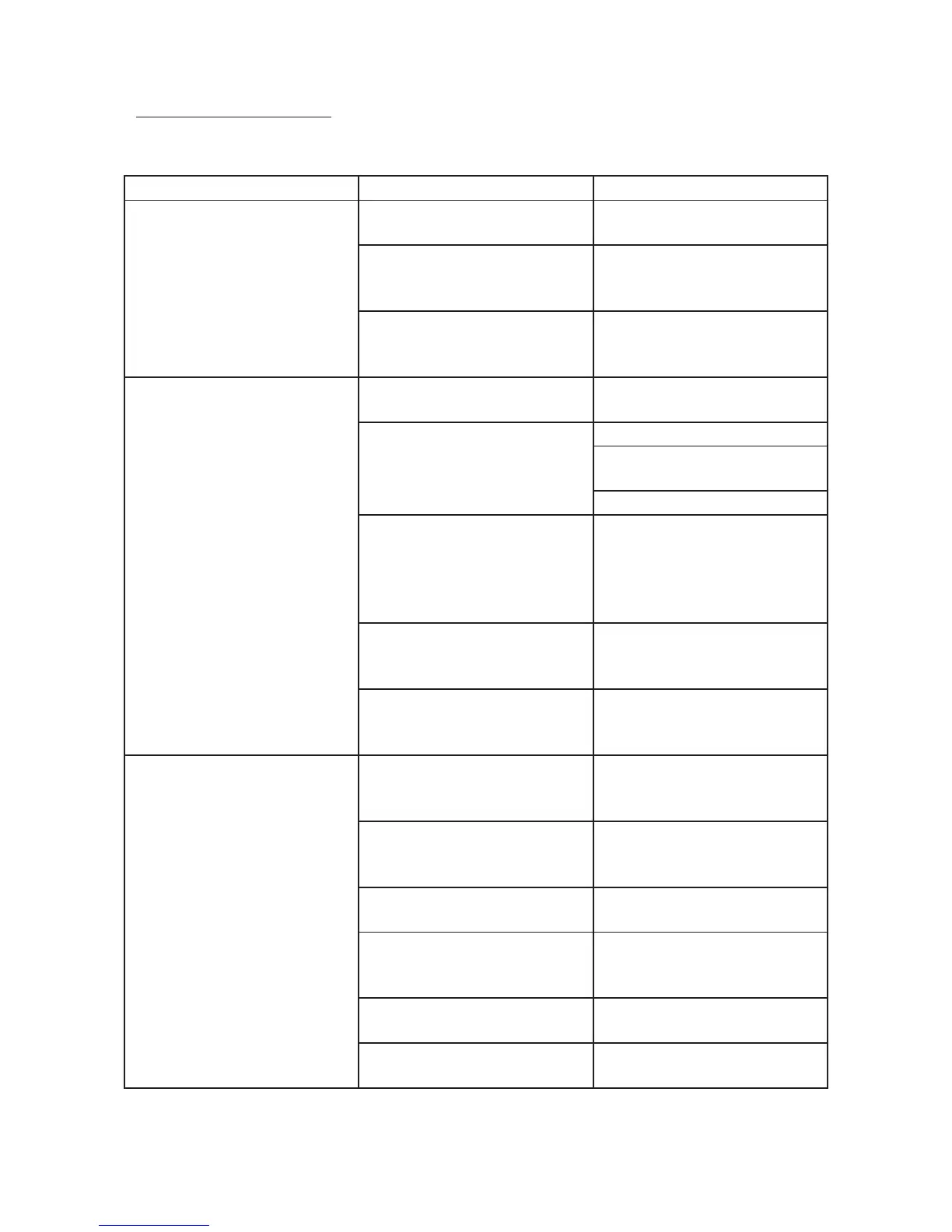

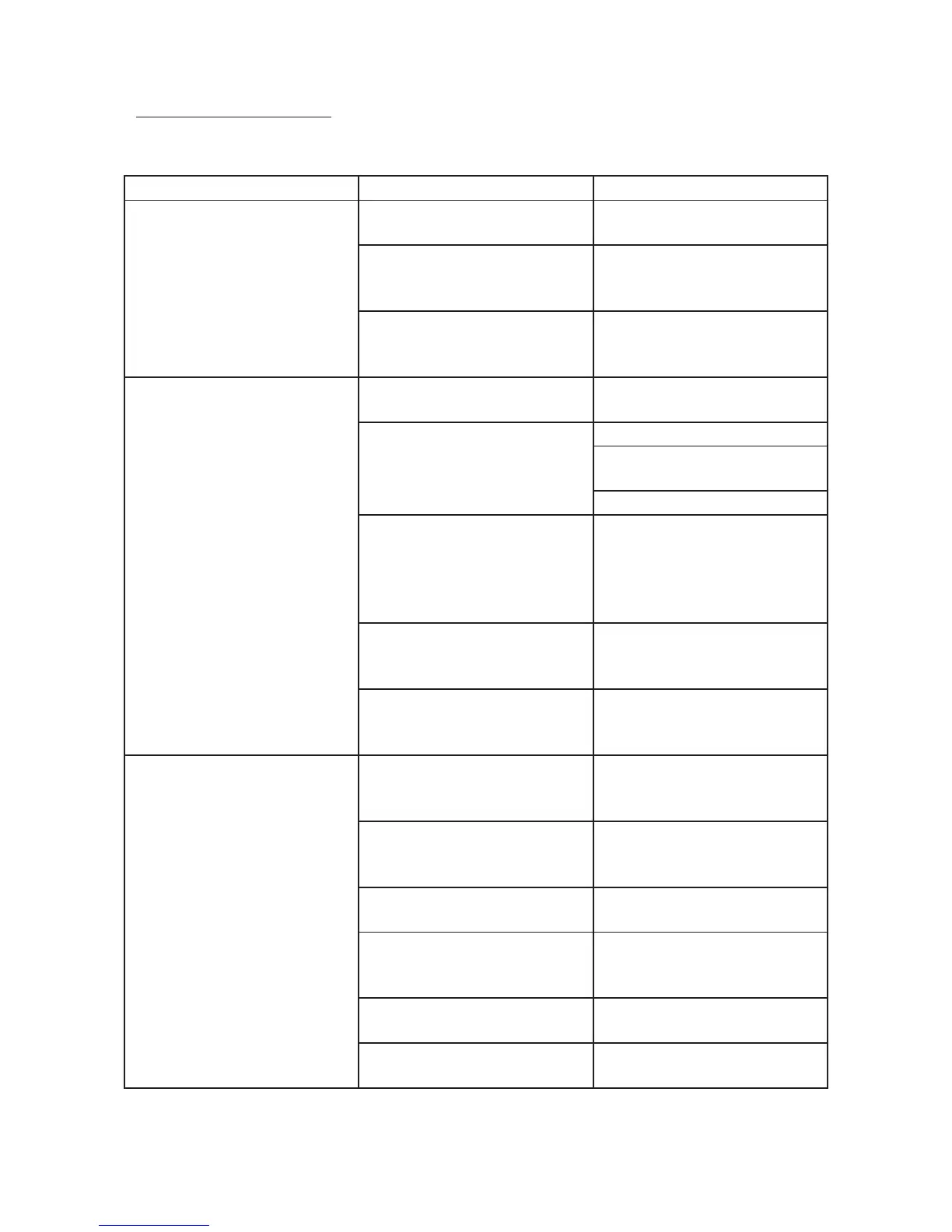

5.1. Troubleshooting

The following table offers you a guide for the most common causes of defects, which can occur on the labelling

machines verify on it if the detected defects are included in this table in order to nd the possible solutions.

Problem Possible cause Solution

Slanted labelling

Machine not oriented compa-

red to the product

Verify the position of the ma-

chine

Alignment of the label in the

machine

Check the position of coil-hol-

der plate and paper guide rings

Wet product Place labels only on perfectly

dry products

Curling of the label or labelling

with air bubbles

Too high ejection speed Adjust the speed of the label-

ling machine

Uneven products’ surface

Mount optional adapters

Improve the product surface

quality whenever possible

Labelling machine speed lower

than the transport speed

Adjust the labelling machine

speed to the transport speed

or vice versa according to the

limit of the labelling machine

Too hot product Cool the products before label-

ling

Product surface excessively ir-

regular or made of material not

compatible with the used labels

Refer to the labels’ supplier

Application error

Dirty or wrongly adjusted

photocell

Adjust the reading sensor or

clean it if dirty

Label stop sensor wrongly

adjusted or dirty

Adjust the reading sensor or

clean it if dirty

Interspazio delle etichette

(GAP) irregolare

Check the labels

Badly oriented

Check that the orienter’s adju-

stment are t to the product to

be labelled

The surface of the product is

dirty

Just label clean product

Irregular speed

Check that the feeding speed of

the transports band is even

Loading...

Loading...