8 Servicing

8.2 Servicing schedule

Series HVX vacuum circuit-breakers

require regular inspections. The in-

tervals depend on the strain to which

the switches are subject during ope-

ration, and on the operating conditi-

ons.

In case of frequent condensation or

air pollution (dust, smoke or corrosi-

ve gases), the maintenance intervals

must be adapted to the actual condi-

tions.

IMPORTANT:

The circuit-breaker opera-

ting company is responsible

for complying with the spe-

cified maintenance intervals and for

performing maintenance according

to the actual operating and ambient

conditions.

In case of queries or ambiguities,

please contact the manufacturer.

Only specialist electricians certified

by the manufacturer for maintenance

work regarding series HVX vacuum

circuit-breakers and who have the

required knowledge regarding ope-

ration of medium-voltage switchgear

are permitted to perform maintenan-

ce and cleaning work.

Warning!

Observe the safety pro-

visions of Chapter 1.5.

Warning!

Risk of injury:

The circuit-breaker

must not be disassem-

bled for maintenance

work.

1. On principle, the 5 safety rules

applicable for electrical enginee-

ring must be complied with befo-

re maintenance work on the cir-

cuit-breaker is started:

• Isolate switchgear from power

supply

• Prevent it from reclosing

• Verify it for zero voltage

• Earth and short-circuit it

• Cover or bar off adjacent live

components.

2. Switch off the supply voltage for

the circuit-breaker drive and se-

cure it against reclosing.

3. Release the energy-storing devi-

ce by performing the correspon-

ding operating sequence on the

circuit-breaker OFF – ON – OFF

(see Chapter 7) and re-mount

the drive´s transport securing de-

vice (see Chapter 6).

22

8.1 Safety

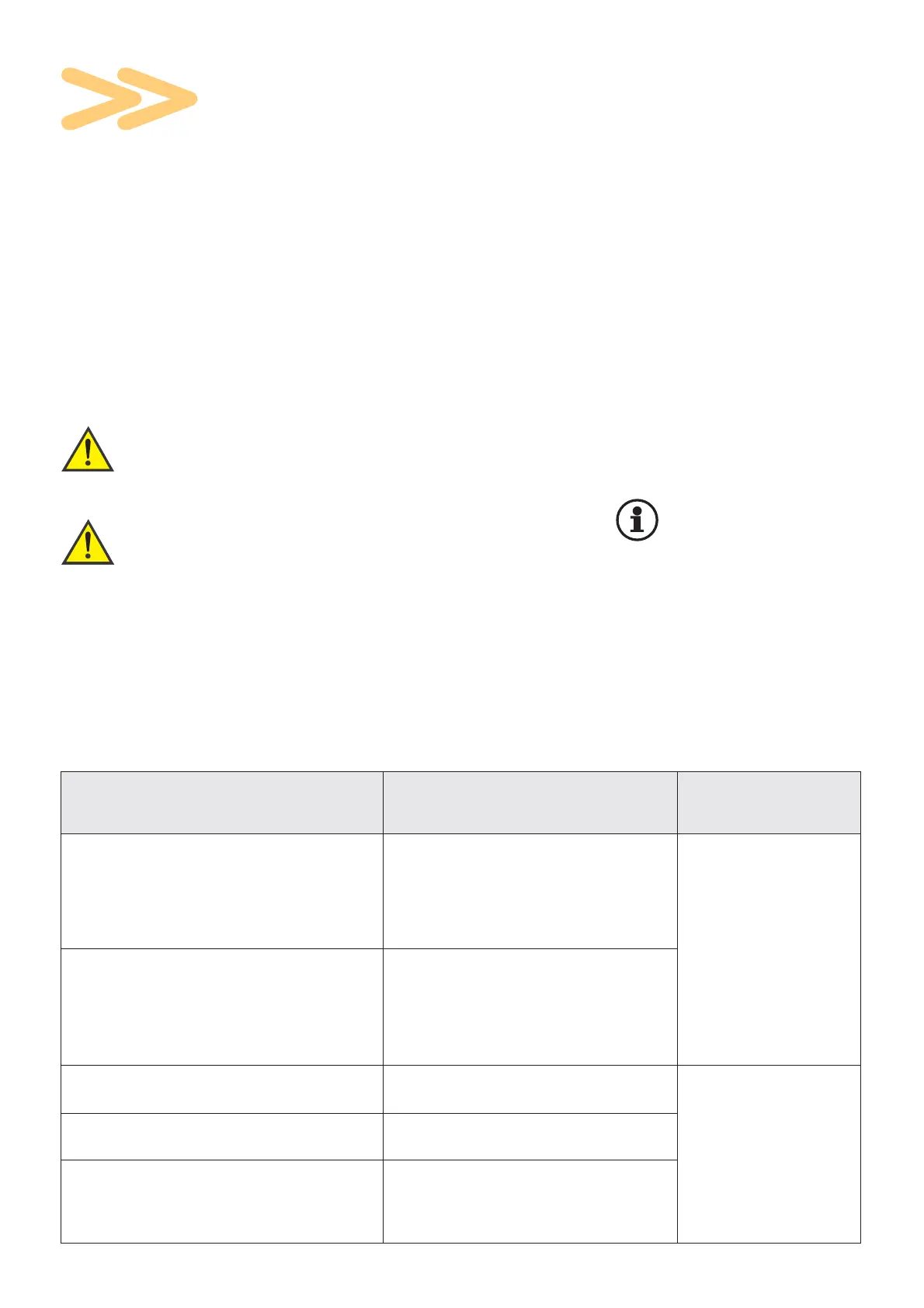

Servicing schedule

Maintenance intervals (ambient conditions

according to IEC 60 694)

Maintenance work

Qualification/position

performing the work

at least every 4 years

• Check for contamination/condensation

and damage

• If necessary, clean circuit-breaker/with-

drawable part (see section 8.3) and

perform several switching tests

Staff qualified accordingly

for the work to be done

after 20 years

• Clean, grease circuit-breaker/withdra-

wable part (see Chapter 8.3 and 8.6)

and perform several switching tests

• Check releases and blocking coils for

proper working order

after 10,000 operating cycles of the circuit

breaker

Revision of the circuit breaker

Manufacturer's Service

Center

after 1,000 operating cycles of the withdrawa-

ble part

Revision of the withdrawable part

once the max. admissible number of breaking

operations for the vacuum chambers has been

reached (see section 8.7)

Replace vacuum chambers

Loading...

Loading...