24

Warning!

Comply with safety pro-

visions (Chapter 1.5).

Warning!

Risk of injury:

Circuit-breakers and

drives must not be dis-

assembled for service and

maintenance work.

Important:

The following elements

must not be lubricated:

- Motor

- Electric releases

- Push switches

- Blocking coils

- Auxiliary switches

- Ball bearings

Important:

Only approved lubricants

may be used (section 9.2).

Preparation

Remove the withdrawable part from

the switchgear cubicle for inspection

(see instructions for the panel con-

cerned). Remove the cover plate of

the circuit-breaker drive and re-

mount the drive´s transport securing

device.

8.6 Lubrication instructions

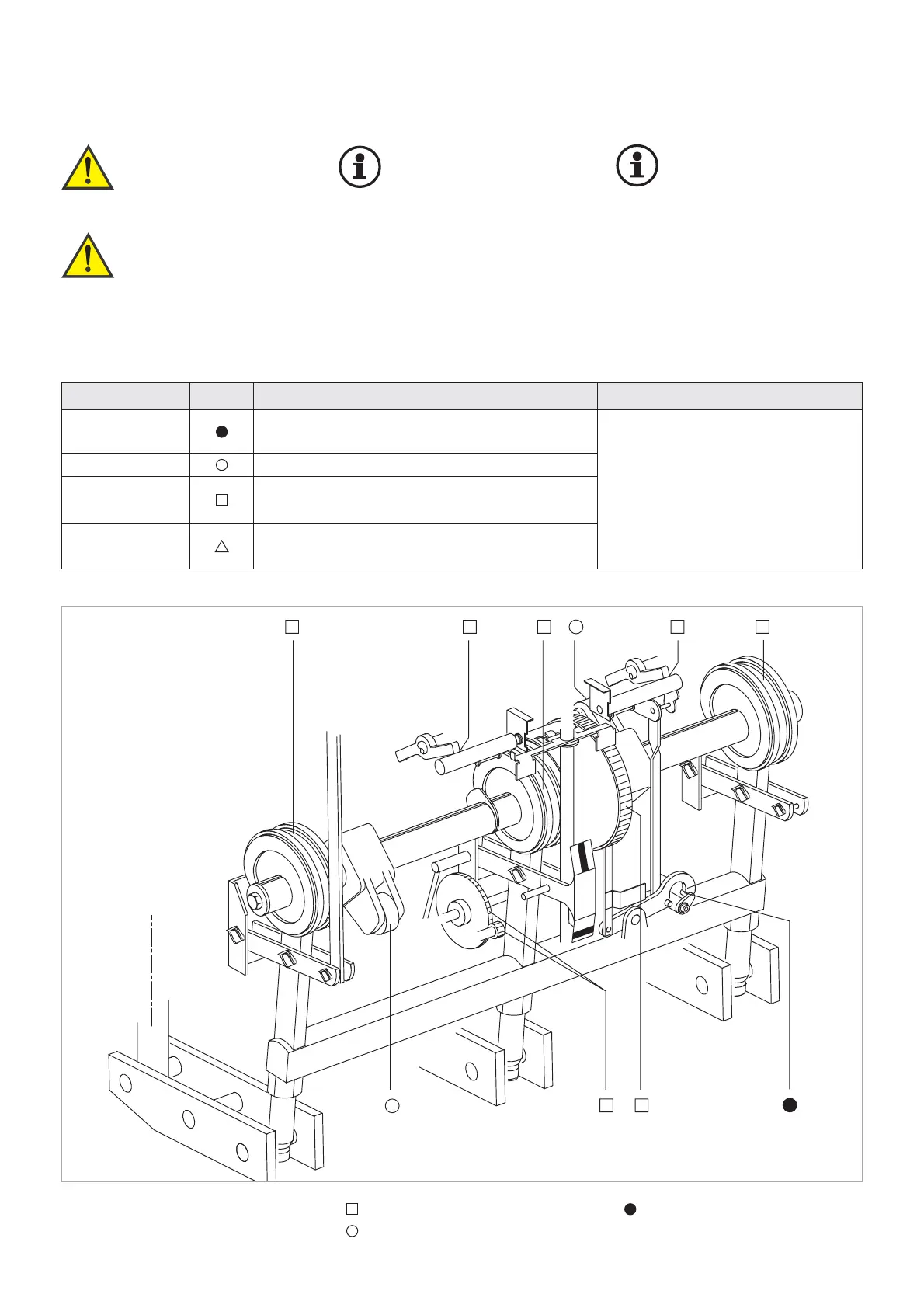

Fig. 8.1

Circuit-breaker drive mechanism

High-pressure grease

Cryogenic grease

Lubrication points inside the circuit breaker´s drive

Silicon grease

Lubricant Symbol Lubrication points Lubrication procedure

Silicon grease

Drive: lever on plastic housing of spring charging

mechanism

Clean lubricating points using a lint-

free cloth or a soft paint-brush, if ne-

cessary using cleaning agent (use

sparingly, just moisten points of lubri-

cation).

Apply a thin coat of lubricant (using

e.g. a paintbrush).

Cryogenic grease

Drive: roller levers

High-pressure

grease

Drive: cam discs, cogwheels and other friction

points

Contact lubricant

Kontasynth

Moving contacts, earth bar

Loading...

Loading...