29

The following elements must be

used for all metal screw couplings:

• Screws and bolts:

Grade ≥ 8.8

• Nuts:

Grade 8.

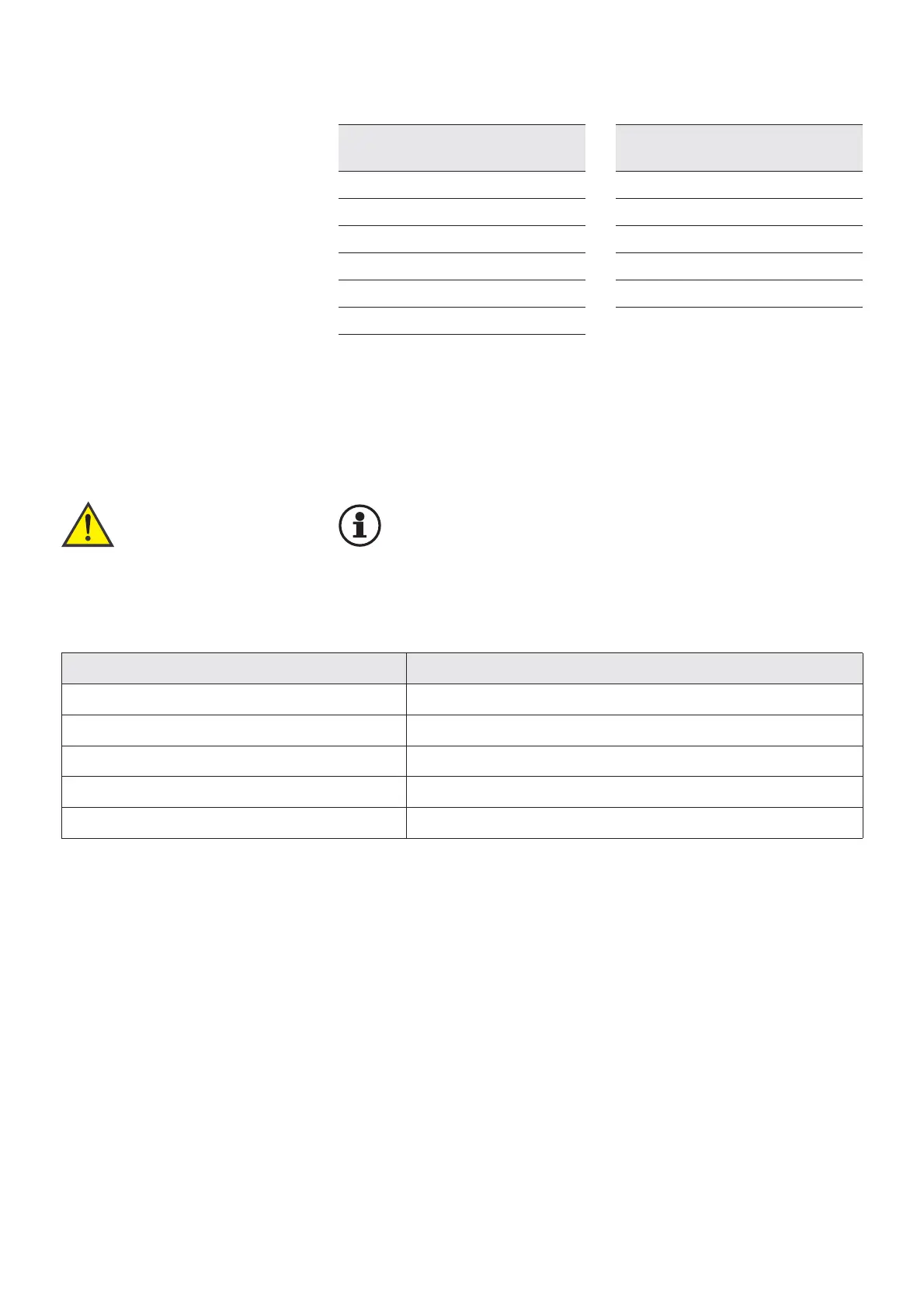

Table 1:

Hex. bolts and socket-head caps-

crews (except slotted screws) and

nuts

Table 2:

Screw coupling between switching

device and conductor bar with cop-

per as conductor material

9.3 Screw fastenings

Thread

size

Tightening torque

[Nm]

min. max.

M5 3,8 4,7

M6 7 9

M8 16 24

M10 36 44

M12 63 77

Thread

size

Tightening torque

[Nm]

min. max.

M6 5,5 7,5

M8 15 19

M10 30 40

M12 60 76

Important:

Caution when handling

bars insulated by heat-

shrinkable sleeves: The

heat-shrinkable sleeve must not get

into contact with lubricant (swelling).

Important:

Contact areas coated with

lubricant Kontasynth should

not be touched, if possible.

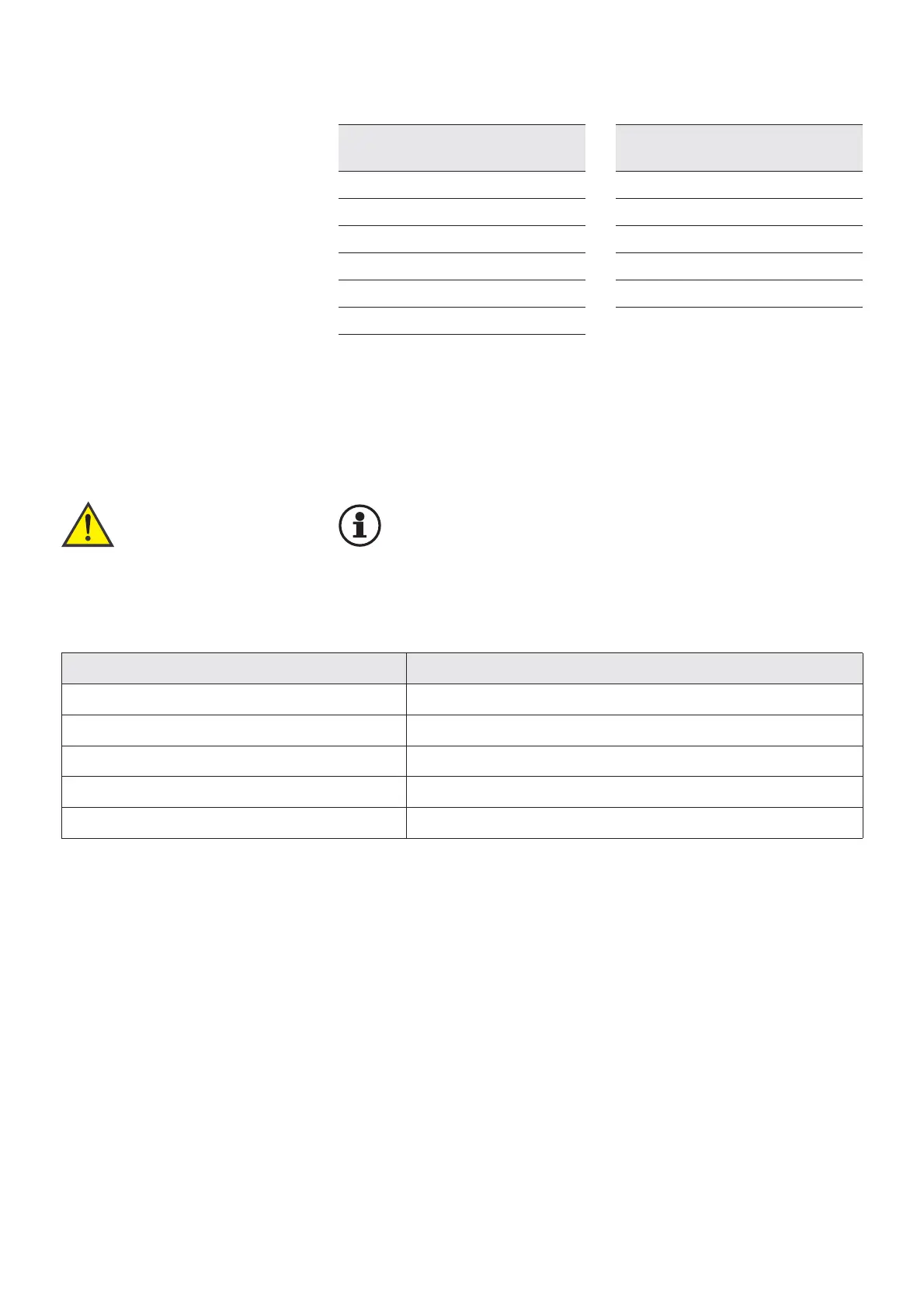

Material of contact surfaces Pre-treatment

Silver-plated contact surfaces

Clean

1)

Copper or copper alloy

Clean

1)

, expose metallic surface

2)

Aluminium

Clean

1)

, expose metallic surface

2)

Zinc-plated steel

Remove passivation, not, however, the zinc layer

3)

Hot-galvanized sheet-metal

Clean

1)

, passivation need not be removed

9.4 How to treat the contact surfaces

1. Contact surfaces must be subjected to preliminary treatment before screw-fastening:

1)

Clean by means of lint-free cloth; use cleaning agent in case of serious contamination (see above)

2)

Expose metallic surface

– by treating the entire surface with emery cloth or a rotating grinding tool (grain size 100 or 80) or

– using a wire brush which is clearly marked for use exclusively for aluminium or exclusively for copper

3)

using a brass brush, steel brush

2. Immediately after the pre-treat-

ment, coat the contact surfaces

with lubricant Kontasynth so

that the space between the

contact surfaces is completely

filled once the screws have

been fastened.

Loading...

Loading...