11

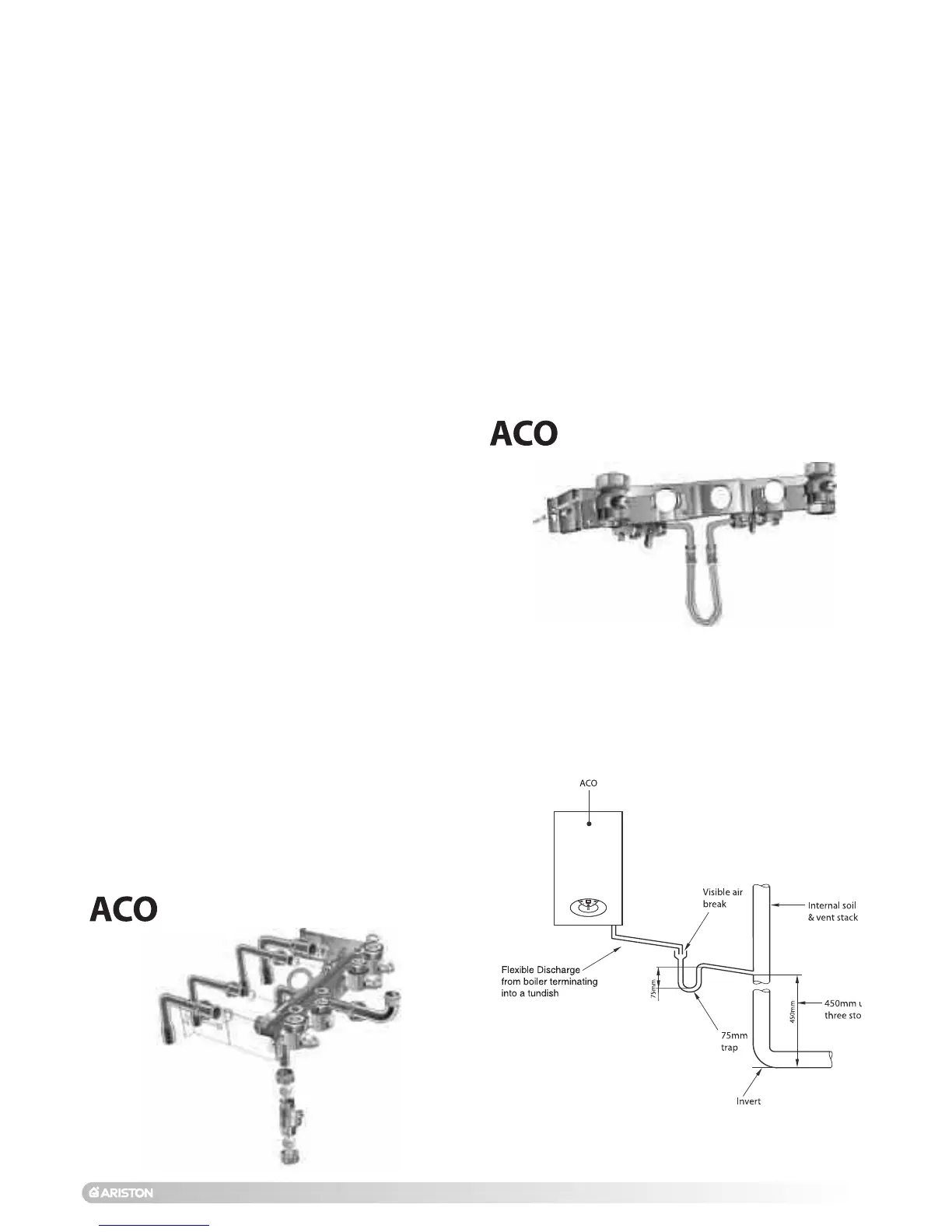

The discharge pipe must be terminated in a suitable position:

i) Connecting in to an internal soil stack (at least 450 mm

above the invert of the stack). A trap giving a water seal of

at least 75 mm must be incorporated into the pipe run,

there also must be an air break upstream of the trap.

ii) Connecting into the waste system of the building such as

a washing machine or sink trap. The connection must be

upstream of the washing machine/sink (If the connection

is down stream of the waste trap then an additional trap

giving a minimum water seal of 75 mm and an air break

must be incorporated in the pipe run, as above.

iii) Terminating into a gully, below the grid level but above the

water level.

iv) Into a soakway.

N

OTE: If any condensate pipe work is to be installed externally,

then it should be kept to a minimum and be insulated with a

waterproof insulation and have a continuous fall.

Some examples of the type of condensate drains can be

found on pages 11 and 12.

AIR RELEASE POINTS:

These must be fitted at all high points where air naturally

collects and must be sited to facilitate complete filling of the

system.

The appliance has an integral sealed expansion vessel to

accommodate the increase of water value when the system is

heated.

It can accept up to 7 l (1.5 gal) of expansion water. If the

heating circuit has an unusually high water content, calculate

the total expansion and add an additional sealed expansion

vessel with adequate capacity.

MAINS WATER FEED - CENTRAL HEATING:

There must be no direct connection to the mains water supply

even through a non-return valve, without the approval of the

Local Water Authority.

FILLING:

A method for initially filling the heating system is supplied with

the connection kit. The filling loop is connected between the

cold water inlet and the central heating flow connections, and

incorporates a non-return valve. To operate the filling loop, it

is necessary to open both quarter turn handles, once the

required pressure has been achieved, close both handles and

disconnect the hose in accordance with water byelaws and

cap off with the cap supplied. NOTE: The installer should

ensure that there are no leaks as frequent filling of the

heating system can lead to premature scaling of the main

exchanger and failure of hydraulic components.

DOMESTIC WATER

The domestic water must be in accordance with the relevant

recommendation of BS 5546:1990. Copper tubing to BS EN

1057:1996 is recommended for water carrying pipe work and

must be used for pipe work carrying drinking water, a scale

reducer should also be used to reduce the risk of scale

forming in the domestic side of the heat exchanger.

UNDER FLOOR HEATING SYSTEMS:

In the event of an under floor heating system, fit a safety

thermostat on the boiler flow (see Section 2.12). This

thermostat should be positioned at a safe distance from the

boiler to ensure the correct operation of the same. If the

thermostat is positioned too close to the boiler, the water

remaining in the boiler after domestic hot water has been

drawn will flow into the central heating system and may cause

the thermostat contact to open without there being any real

danger of the system being damaged, this would lead to a

boiler shutdown both in D.H.W. mode and C.H. mode, and the

error code

“E08” would be displayed; boiler operation resumes

automatically when the thermostat contact closes on cooling.

Should the thermostat fail to be installed as recommended, the

under floor heating system can be protected by installing a

thermostatic valve upstream from the thermostat in order to

prevent the flow of excessively hot water towards the system.

27/32 MFFI (COMBI)

27/32 RFFI (SYSTEM)

1. Internal termination of condensate drainage pipe to

internal stack

Loading...

Loading...