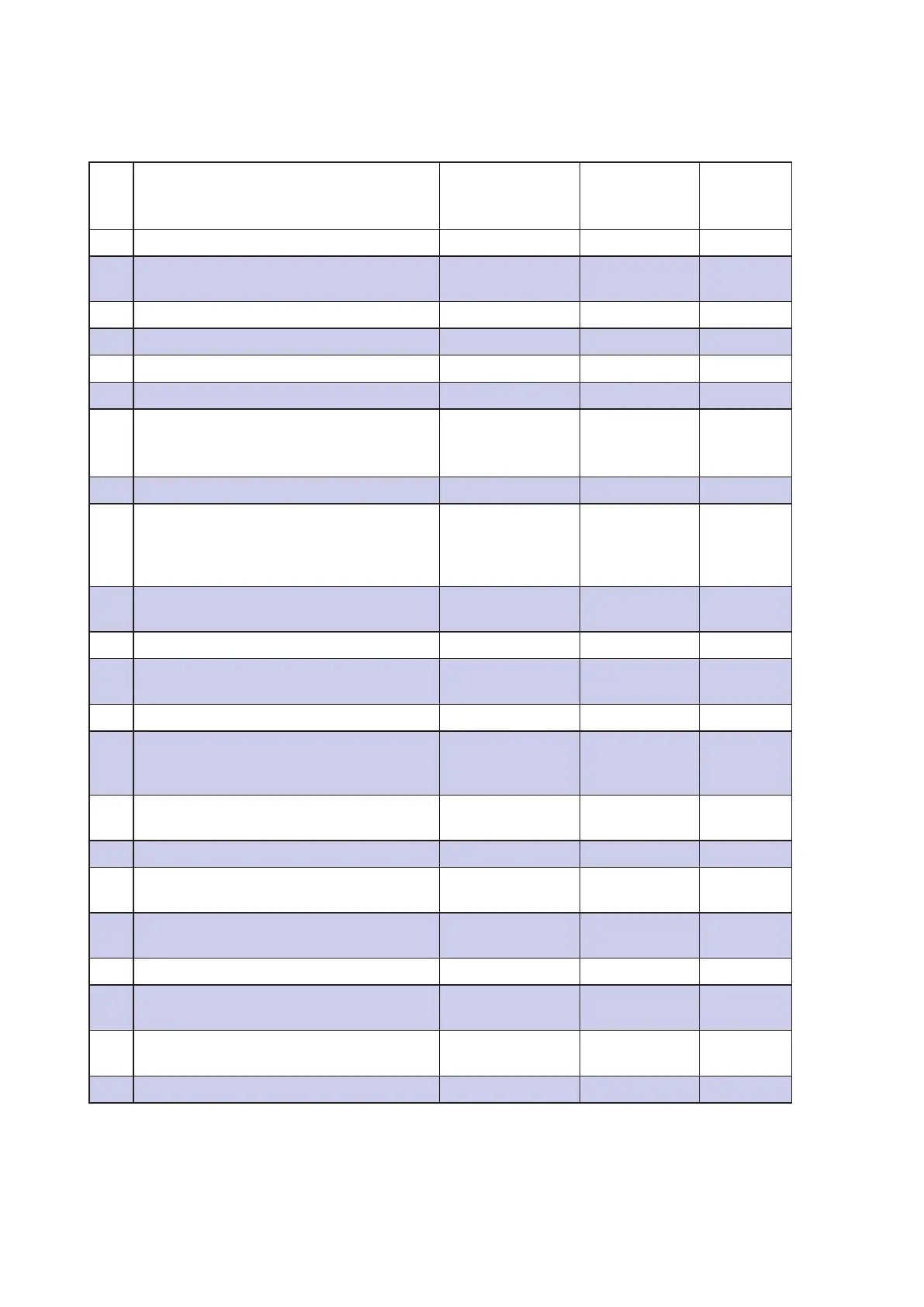

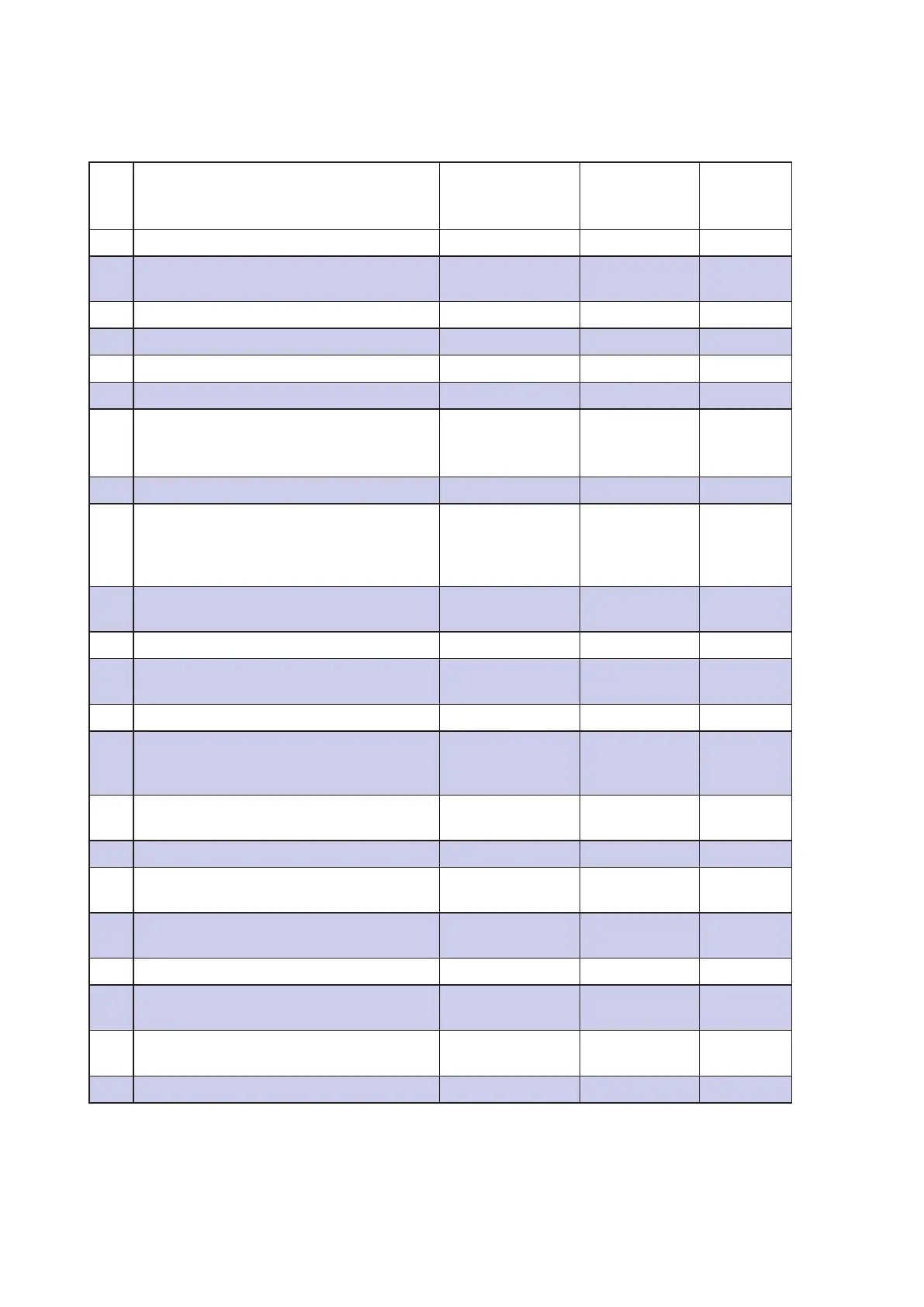

18

Measure Every year /

10,000 cycles

Every other

year /

20,000 cycles

Time*

(minutes)

2.6 Check the mounting for the goods holder. • 2

2.7 Check that the overow drain connection to

the chamber is tight.

• -

2.8 Clean the inside of the ushing chamber. • 10

3 Process tank

3.1 Clean as required. • -

3.2 Check and clean the level sensor. • 5

3.3 Check that the valves are working and that

the connections are not leaking. Clean as

required.

• 10

4 Steam Generators

4.1 Check the connections to the steam

generator for leakage and make sure the

surrounding insulation is intact and no hot

surfaces are exposed.

• 5

4.2 Check that the steam generator is working

properly.

• 10

5 Main pump

5.1 Check that the main pump is rmly attached

and that there are no leaks in the connections.

• 5

6 Dosing system

6.1 Check the hoses between the dosing pump

and the detergent container. Replace if

necessary.

• 5-10

6.2 Check the dosage amount. Adjust if

necessary.

• 10-30

6.3 Replace hose in the dosing pump. • 5

6.4 Check that the empty container alarm

works. Clean or replace as necessary.

• 5

6.5 Check the function of the check valve in the

steam generator

• 5

7 Drainage connection

7.1 Check that the drain connection is rmly

attached and that it is not leaking.

• 5

7.2 Check the condensation cooling nozzle

head (option).

• 5

8 Steam inspection (Option)

Loading...

Loading...