SECTION

C

21

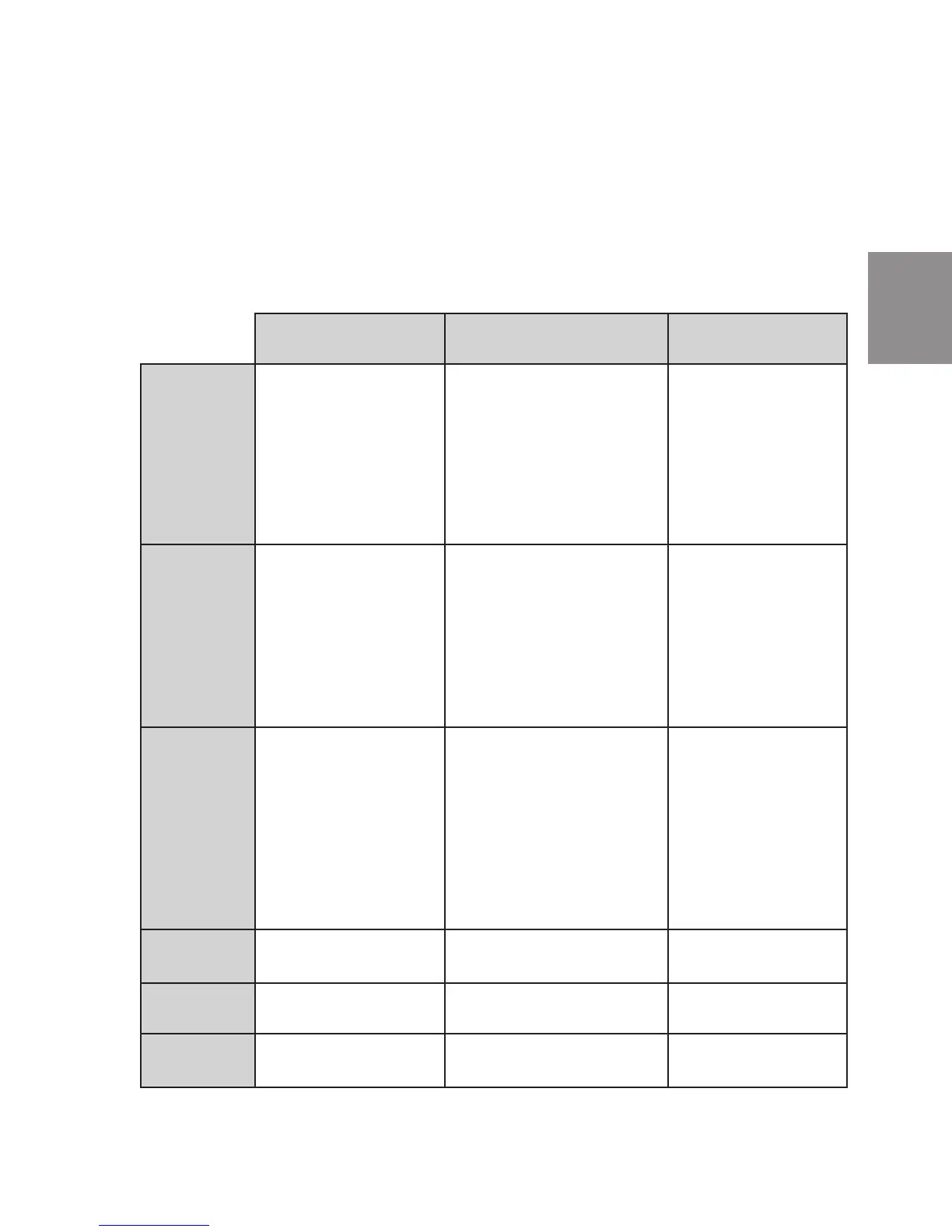

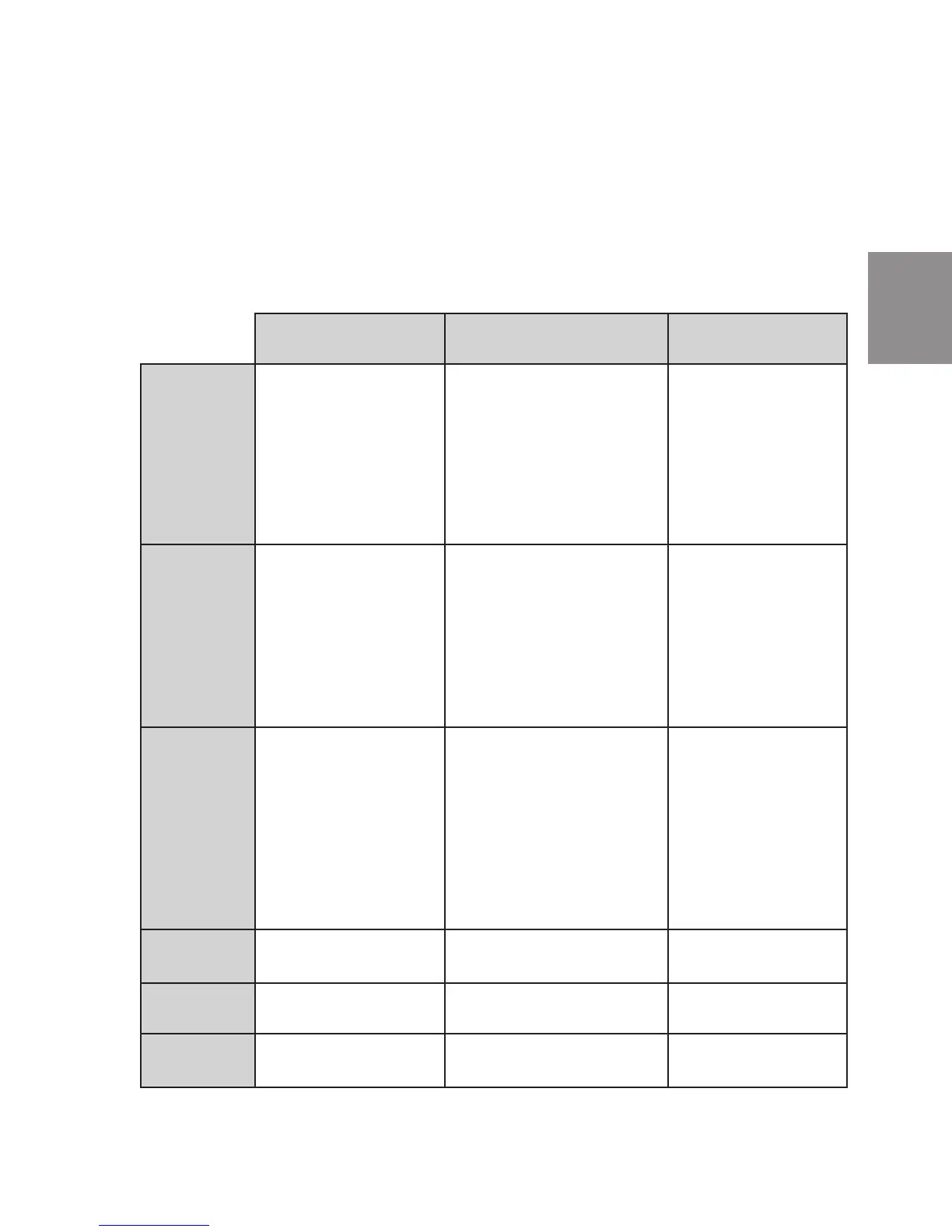

Regulatory Review and Guidelines

for QA/QC Protocols

COMPETENCY CHECKLIST

Joint Commission on

Accreditation of Healthcare

Organizations (JCAHO)

Clinical and Laboratory

Standards Institute (CLSI)

(Formerly NCCLS)

Clinical Laboratory

Improvement

Amendments (CLIA)

Personnel/Training • Staff members can describe

or demonstrate their roles and

responsibilities (HR.2.20).

• Participate in ongoing

in-services.

• Education is documented

(HR.2.30).

• Competence to perform job

responsibilities is assessed,

demonstrated, and maintained

(HR.3.10).

• Formal training and written

examination.

• Follow manufacturer’s

instructions.

Quality Assurance • Current and complete policies

are available to the person

performing the test.

• Written policies and

procedures for: specimen

collection,identication,and

requiredlabeling;specimen

preservation;instrument

calibration;qualitycontroland

remedialaction;equipment

performanceevaluation;

test performance.

• Follow manufacturer’s instructions

for calibration.

• Written procedure manual.

• Manual contains principles of

operation, reagents/equipment,

calibration, quality control, stepwise

procedure, reporting results,

procedure limitations, references,

supplemental material, review

and updates.

• Follow manufacturer’s

instructions.

Quality Control • Written quality control plan

thatspecieshowprocedures

will be controlled.

• At the least, perform as

frequently as recommended

by manufacturer.

• Should include two levels of

control solution.

• At the least, quality control

procedures are performed

once each day on each

instrument used for resident

testing (PC.16.50).

• On each day of use, two control

solutions(Level1and2)shouldbe

performed per instrument.

•Priortothersttestoftheday,

each operator is to perform a quality

control test.

• Additional checks should be

performed when:

• A new bottle of strips is opened.

• Each time a reagent lot is changed.

• To ensure the strips and meter

are functioning properly.

• Follow manufacturer’s

instructions.

Linearity/Calibration •Linearitynotcoveredin

the standards.

•Initiallyandasspeciedby

manufacturer or as required by

government or accrediting bodies.

• Follow manufacturer’s

instructions.

Prociency Training •Notspecied. • Participate in program that

meets accreditation, federal

and state regulations.

•Notspecied.

Inspections • Currently triennial (APP-5). • Not a certifying agency. • Not subject to routine survey.

• Conducted only when

authorized by the RO.

ARKRAY provides this checklist as a guideline only. These guidelines are subject to change by the

regulating body at any time. Utilize this checklist in accordance with your facility’s policy.

Loading...

Loading...