LUBRICATION

AU104488 C6B 42

11. Install the filler cap and the dipstick.

12. Start the engine. Run the engine at idle for

approximately 2 minutes. Check for oil leaks.

13. Stop the engine.

14. Wait approximately 5 minutes and check the oil

level. If the oil level is below the UPPER mark, add

oil to raise the oil to the UPPER mark. Do not fill the

crankcase above the UPPER mark.

AIR FILTERING SYSTEM

A dirty air filter will restrict air flow to the carburetor,

reducing engine performance. If you operate the machine

in very dusty areas, clean the air filter more often than

specified in the maintenance schedule.

The air filter element should be checked every day,

cleaned every 3 months or 50 hours of operation, and

replaced once a year or every 300 hours of operation.

Each time you service the air filtering system, make sure

all connections and flanges are air tight. Replace all

damaged parts.

Periodically check the connections for wear or damage.

Check to make sure all connections are tight.

Do the following to clean or replace the filter elements.

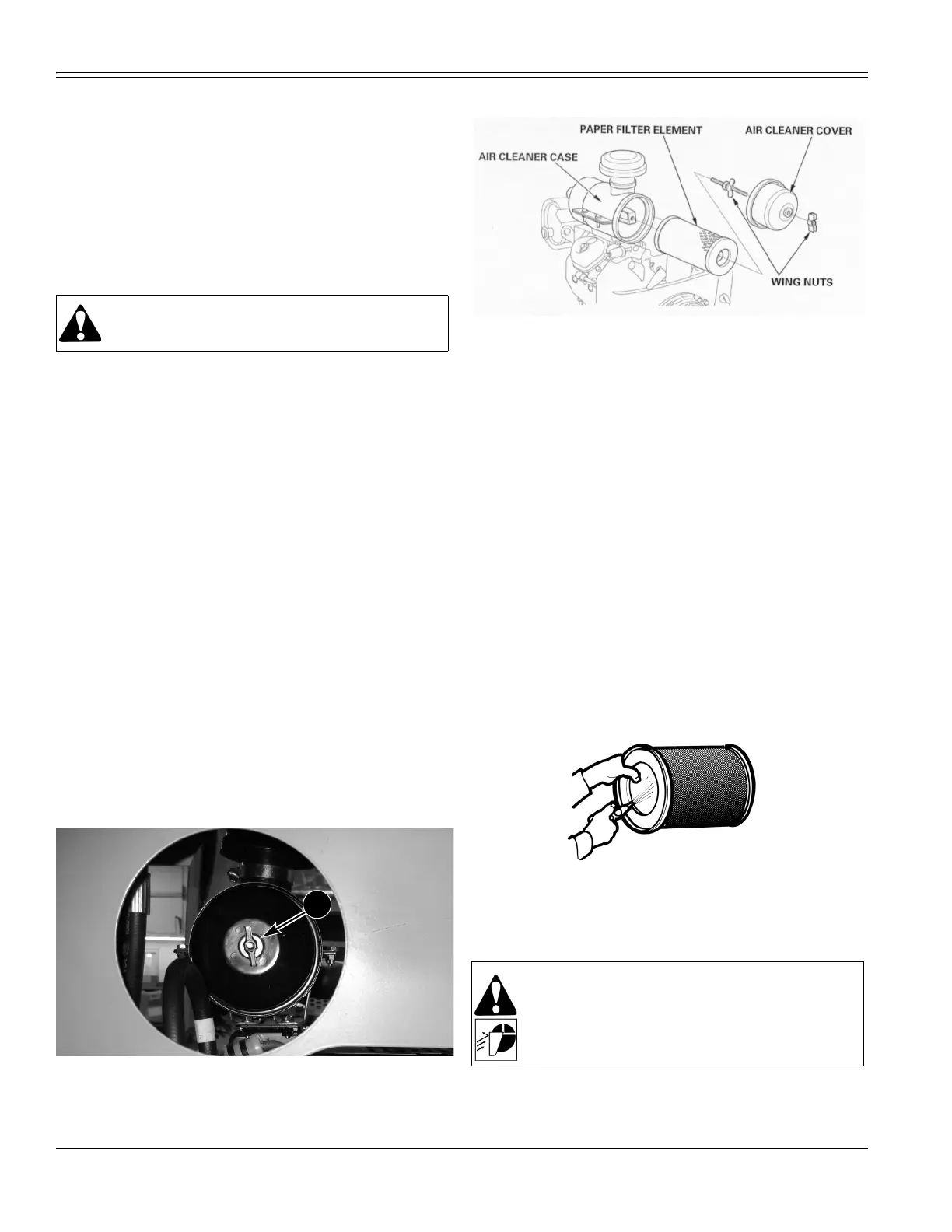

Paper Filter Element

Replace the paper filter element after the element has

been in the machine for one year.

1. Locate the air filter access opening below the control

panel.

RT160010

2. Remove the wing nut (1) on the air cleaner housing

cover, and remove the filter cover from the housing.

RT160046

3. Remove the wing nut from the paper filter element.

4. Remove paper filter element from air cleaner case.

Cleaning the Element

1. Check the dirty element for damage.

2. Check the rubber seal on the end. Push the rubber

seal with your finger. If the rubber seal feels hard and

does not move back to its original shape, discard the

element.

3. Inspect the paper air filter element, and replace it if it

is damaged. Always replace the paper air filter

element at the scheduled interval.

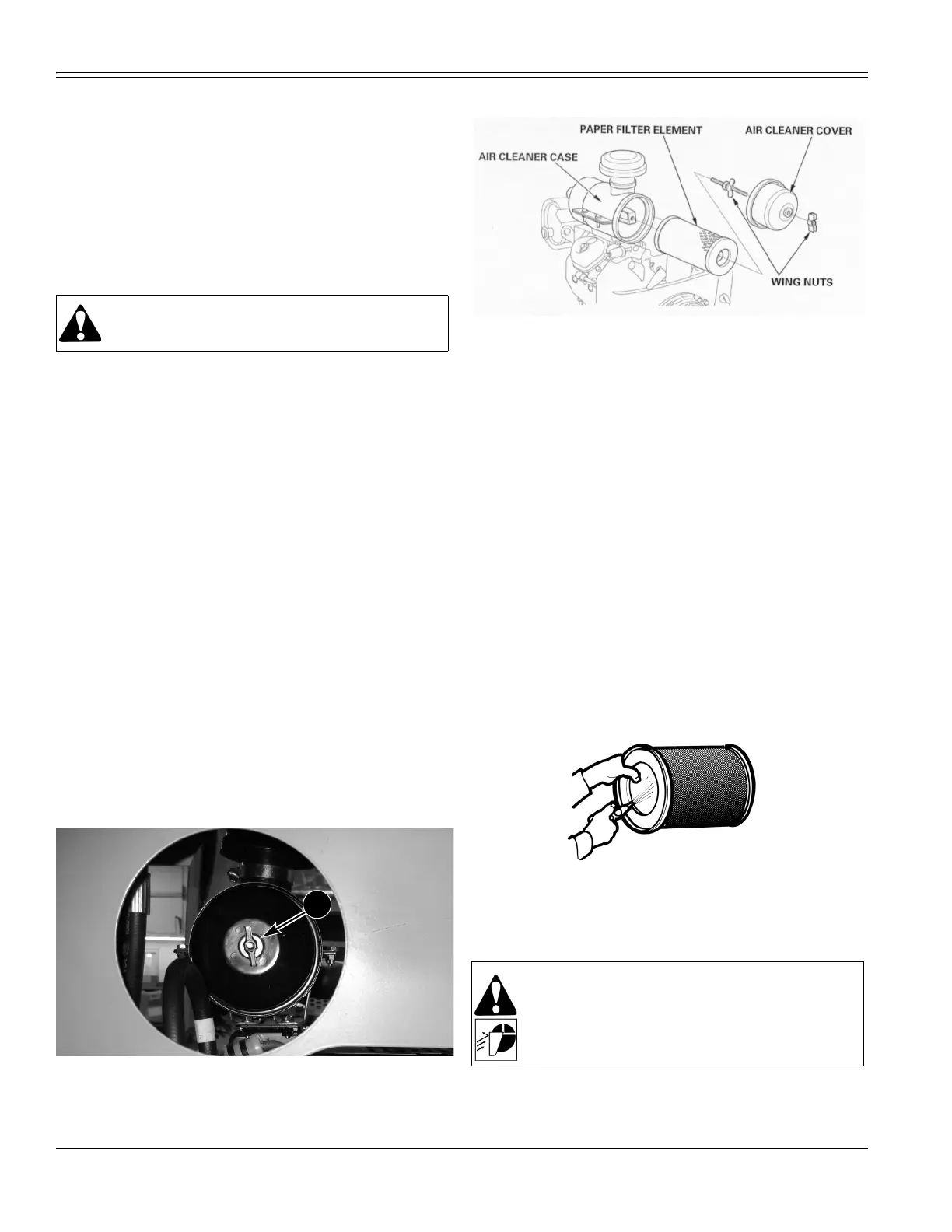

4. Clean the paper air filter if it is to be reused.

Tap the paper air filter element several times on a

hard surface to remove dirt. Never try to brush off

dirt; brushing will force dirt into the fibers. If most of

the dirt and dust is dry, remove the loose dirt with

compressed air. Always wear face protection

when using compressed air.

199L93

NOTE: Blow compressed air through the filter element

from the inside while moving the nozzle up and down and

turning the element. The nozzle pressure must not

exceed 207 kPa (30 psi).

5. Wipe dirt from the inside of the air cleaner case

and cover, using a moist rag. Be careful to prevent

dirt from entering the carburetor air duct.

WARNING:

Never drain oil or remove oil filter

while engine is running.

1

WARNING:

Always wear face protection when

using compressed air.

Loading...

Loading...