Installation & Servicing Instructions ATAG Q-Series

20

6.7.1 Dimensioning of the ue gas and air intake duct

The ue diameter is determined by the total length of the run, including for the

connection pipe, elbows ttings and terminal covers etc and the type and number of

boilers installed into the system.

An undersized ue pipe can lead to disorders. Look at table 1 for the choice of the

system and the correct diameter. The table below shows the maximum ue lengths

with the different boiler outputs. A longer ue gas length can be achieved by increasing

the diameter to ø 100mm.

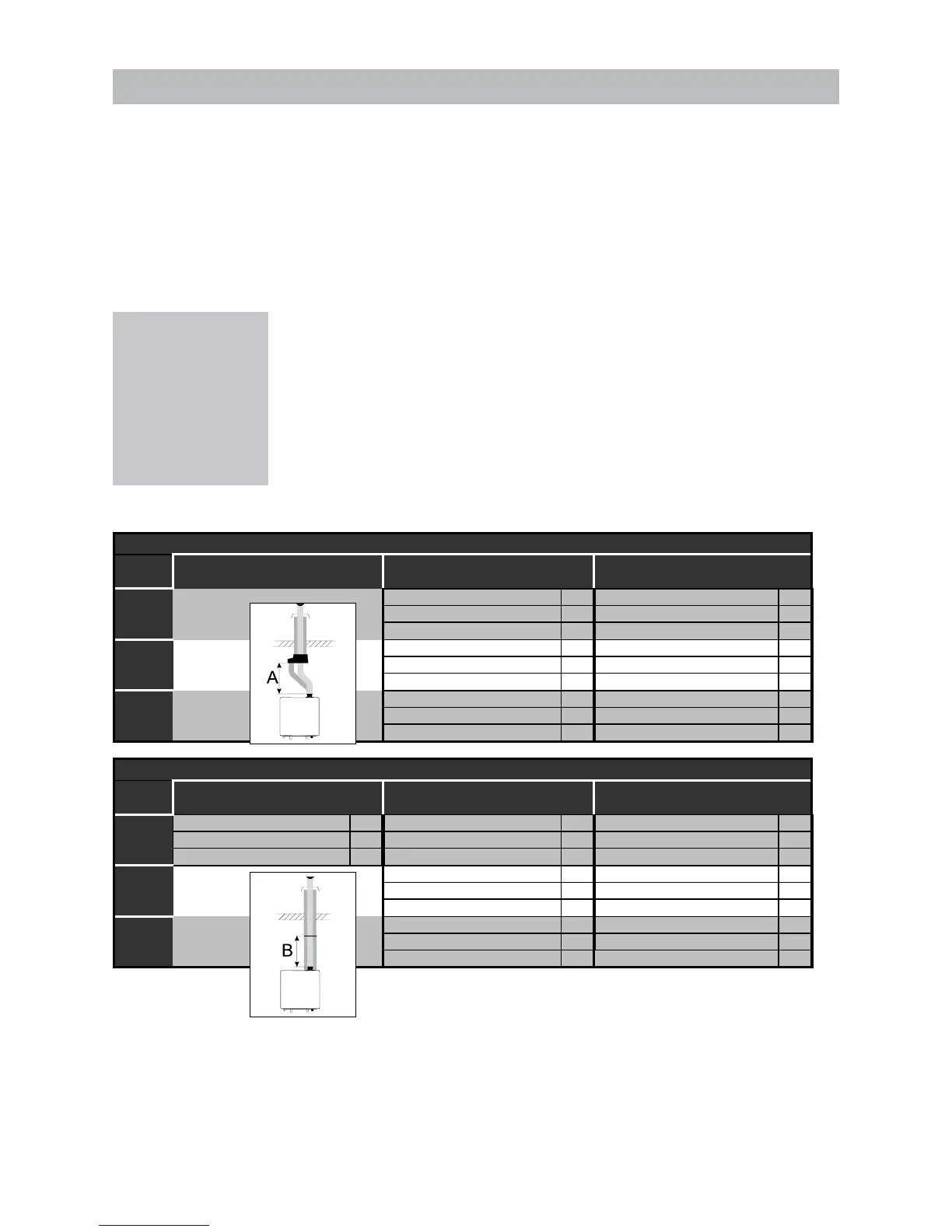

Explanation table 1:

Two pipe ue gas system: maximum noted length = distance between boiler and

roof terminal A

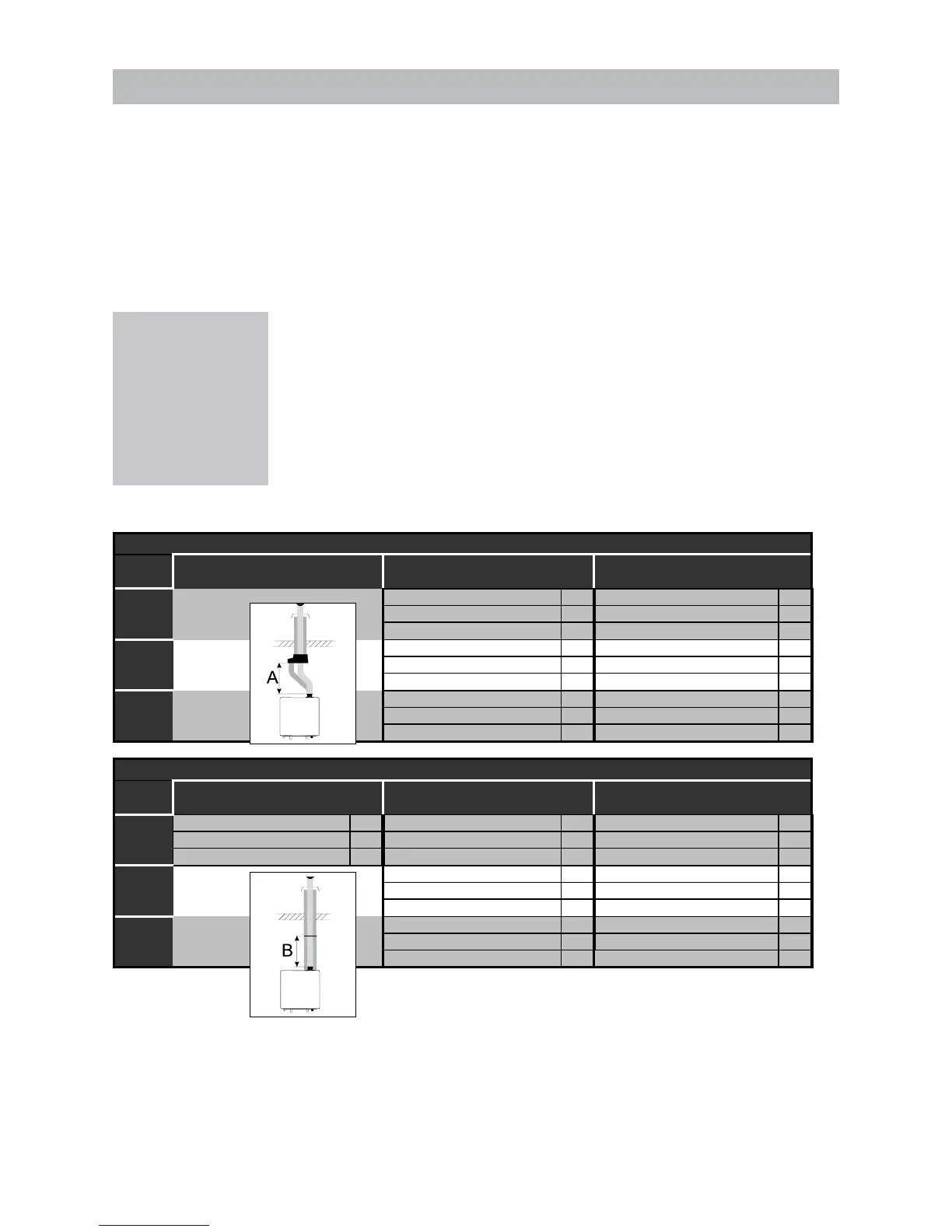

Concentric ue gas system: maximum noted length = distance between boiler and

roof terminal B

When using bends the noted value behind every bend should be deducted from the

maximum straight length.

Pipes with 60/100 diameter are only permitted on wall terminals in

combination with ATAG boilers untill 25kW.

in m

ø100mm

A

in m

16-25 kW Maximum straight lenth 80 31 Maximum straight lenth 100 40

87° bend resistance length -1,5 87° bend resistance length -1,8

45° bend resistance length -0,8 45° bend resistance length -0,9

26-38 kW Maximum straight lenth 80 18 Maximum straight lenth 100 39

87° bend resistance length -1,5 87° bend resistance length -1,8

45° bend resistance length -0,8 45° bend resistance length -0,9

39-60 kW Maximum straight lenth 80 6 Maximum straight lenth 100 18

87° bend resistance length -1,5 87° bend resistance length -1,8

45° bend resistance length -0,8 45° bend resistance length -0,9

ø60/100mm

B

in m

ø80/125mm

B

in m

ø100/150mm

B

in m

16-25 kW Maximum straight lenth 60/100 12 Maximum straight lenth 80/125 31 Maximum straight lenth 100/150 40

87° bend resistance length -1 87° bend resistance length -2,8 87° bend resistance length -2,6

45° bend resistance length -1 45° bend resistance length -1,1 45° bend resistance length -1,1

26-38 kW Maximum straight lenth 80/125 13 Maximum straight lenth 100/150 34

87° bend resistance length -2,8 87° bend resistance length -2,6

45° bend resistance length -1,1 45° bend resistance length -1,1

39-60 kW Maximum straight lenth 80/125 6 Maximum straight lenth 100/150 10

87° bend resistance length -2,8 87° bend resistance length -2,6

45° bend resistance length -1,1 45° bend resistance length -1,1

Concentric flue system

Two pipe flue system + chimney lining

Dimensions ue gas system and air supply system Table 5

Example:

A 25kW with a concentric

ue gas system ø80/125mm

has according to the table a

maximum ue straight length

of 31m In the system that is

going to be put in there are 2

x 45° bends, so the maximum

ue gas length is

31 – ( 2 x 1.1 ) = 28.8 meters.

Loading...

Loading...