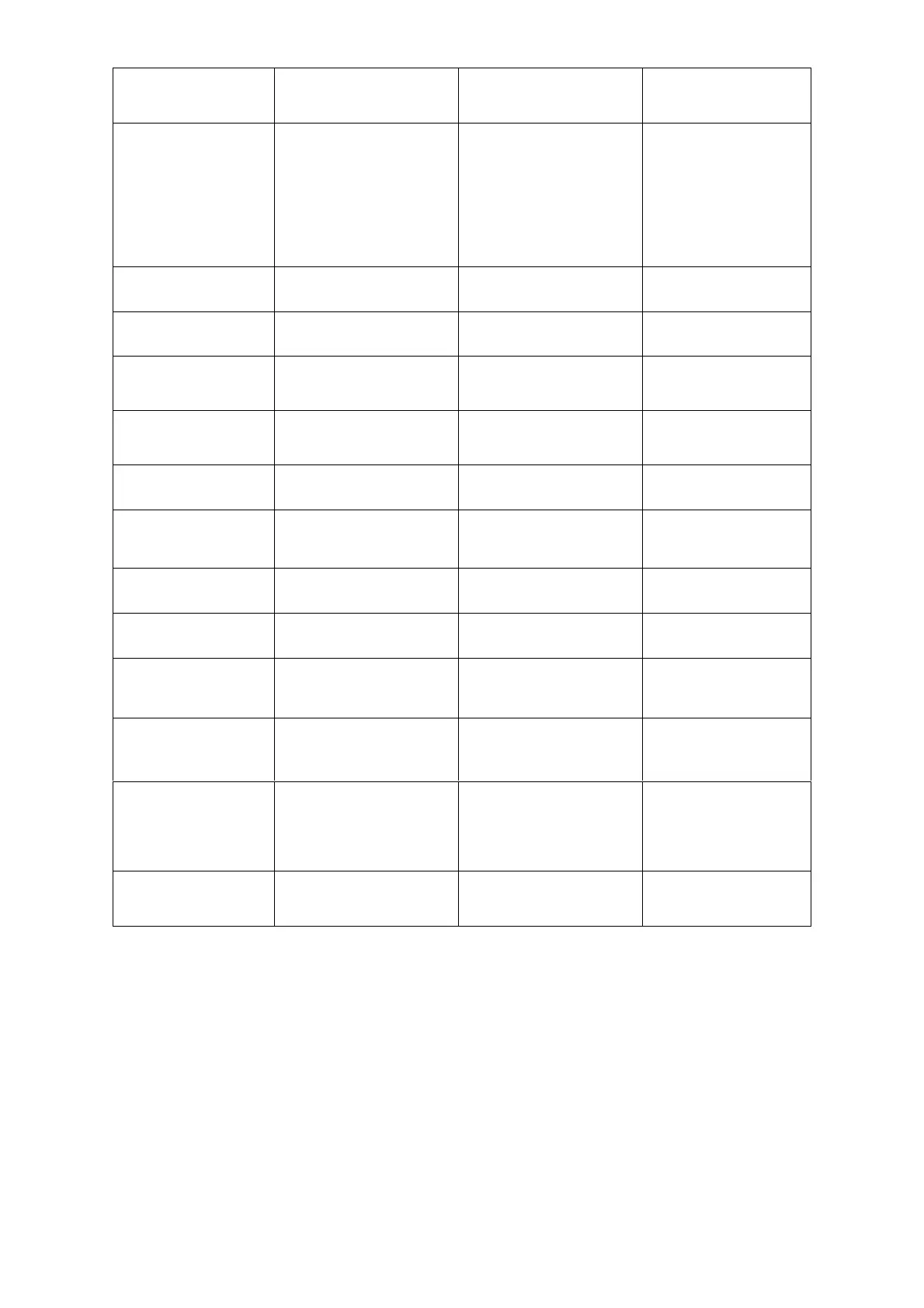

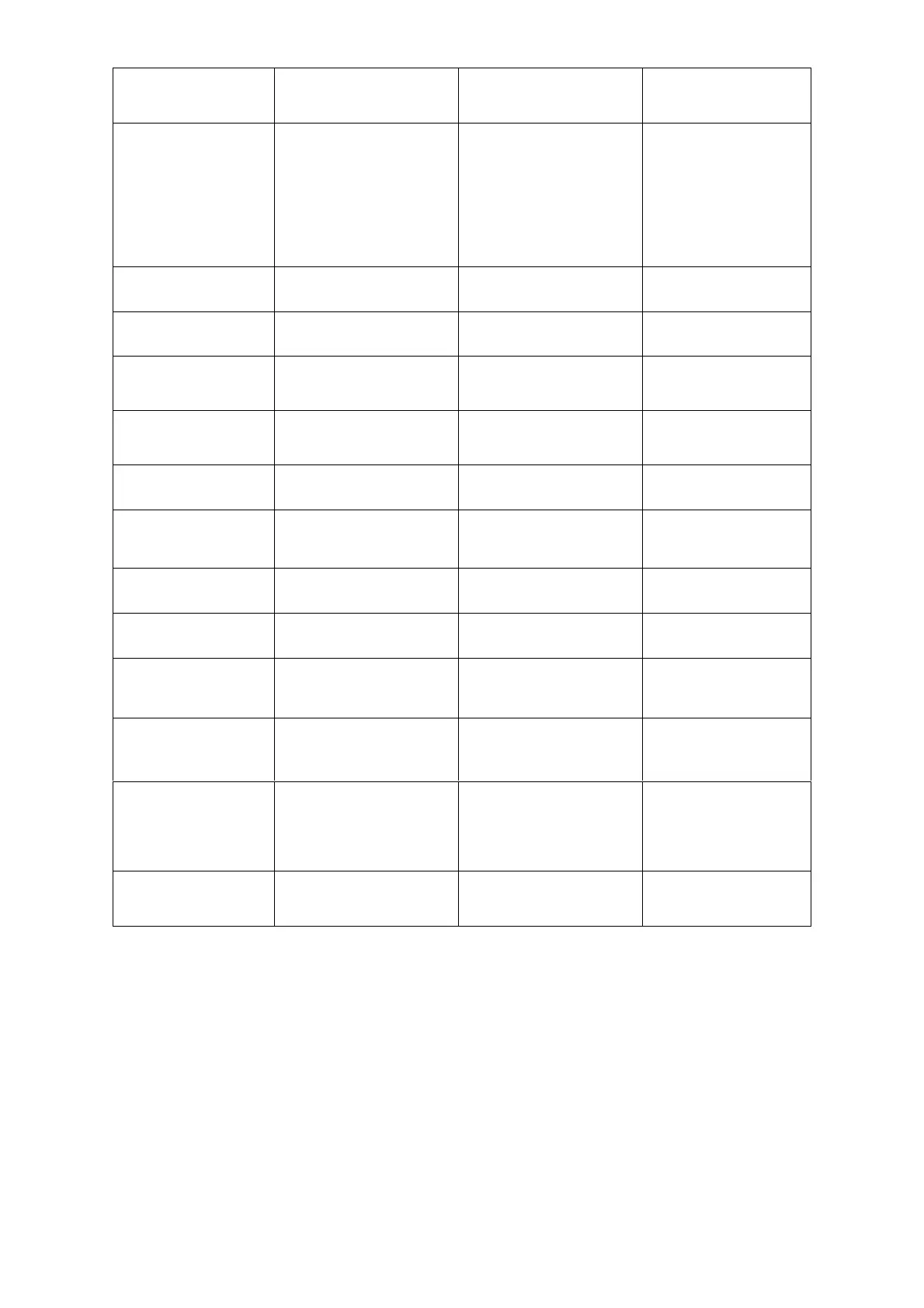

Model S High Speed Sublimation printer

For safety production,

close the cove plate

when printing.

The paper is adsorbed and

printed on the platform under

the work of suction platform

aspirating.

Let paper smoothly

adsorbed on the

platform. Adjust the

head carriage height

when print thick

material, don't leave

any irrelevant item on

platform.

Adjust material tension,

steering

Adjust material tension ,

avoid the paper crumple

Prevent sharp object

scratch and damage the

roller.

Guarantee the material in

stable printing

Adjust the damping

according to paper

feeding situation.

Unrolling air swelling

shaft

Load raw material (paper)

Maximum material

diameter at 400mm

Respond control and

feeding action by sense

the sensor distance

Rolling air swelling shaft

For printed material take

up.

Maximum take-up

diameter 40mm.

Dryer module on the

printer bottom place

Adjust proper temperate

according to actual use

The light will be on if the

it is ready to print or error

report

Control panel for feeding

and take-up

Rolling and unrolling

motor switch

automatically or manually.

Control direction, and set

dryer temperature

Turn on the rolling and

unrolling switch and set

it to “automatic control”

when prepare to print

For ink store, empty

and clean the bucket

every three month.

Loading...

Loading...