2920 1449 00

29

Instruction book

4 MAINTENANCE

Warning Before carrying out any maintenance, repair or adjustment, stop the compressor, press emergency stop button (S2-

Fig. 3.5) and switch off the voltage. Close the air outlet valve and open the manual condensate drain valve(s). 1)

Take precautions to avoid an accidental restart. Apply all relevant safety precautions, including those mentioned

in this book.

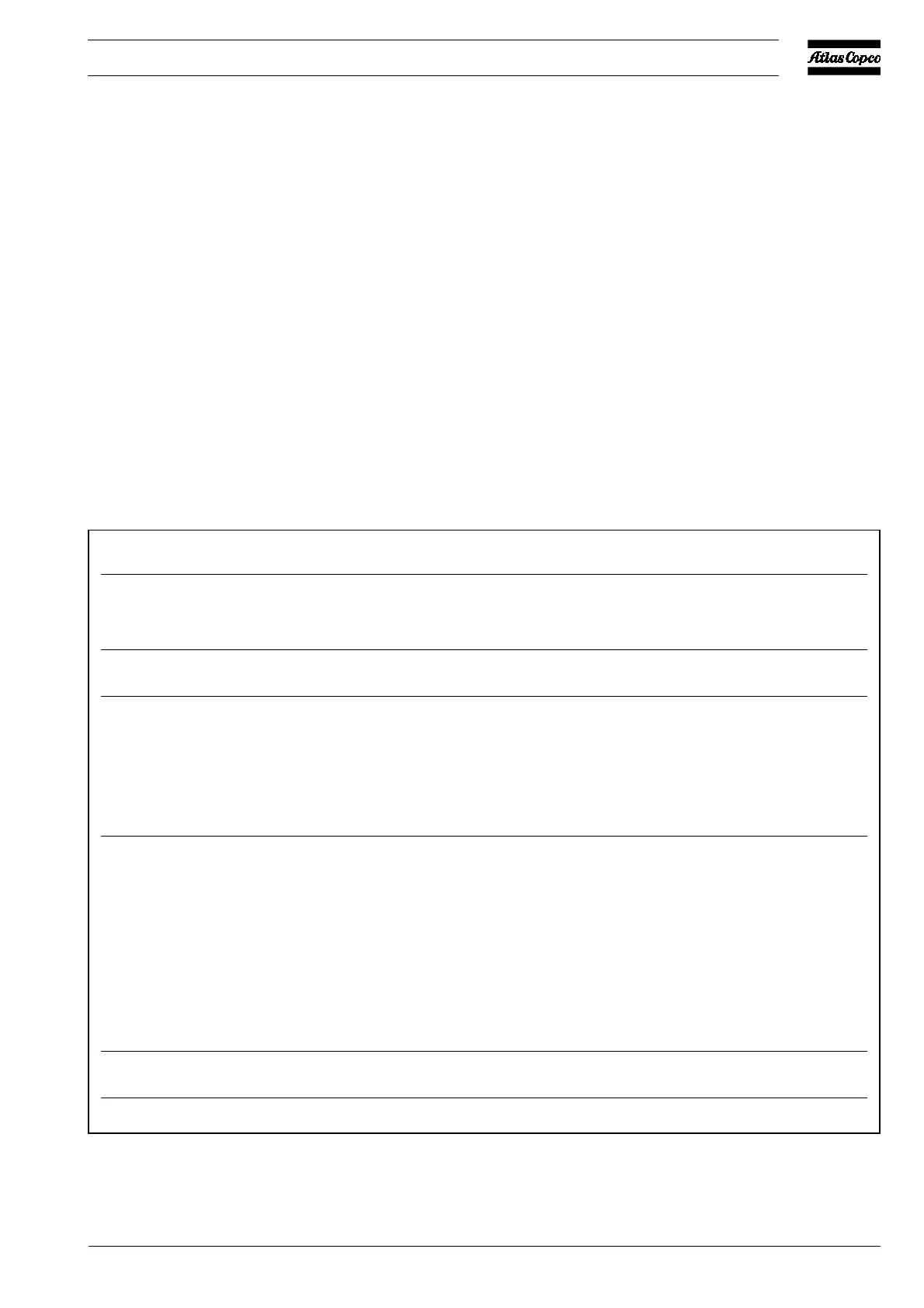

4.1 Preventive maintenance schedule for the compressor 2)

- The schedule contains a summary of the maintenance instructions. Read the related section before taking maintenance

measures.

- In servicing, replace all removed gaskets, O-rings and washers.

- The "longer interval" checks must also include the "shorter interval" checks.

Period 3) Running Consult See notes Operation

hours 3) section below table

Daily -- 3.5/7.1 -- Check readings on display

"---- -- Check that condensate is discharged during loading

Monthly 200 -- 9 If an OSD separator is provided: check the oil level in the oil collector

3-monthly -- 5.3 -- Operate safety valve

"---- -- Remove, dismantle and clean float valve of condensate trap(s)

"---- -- Clean compressor

"---- 4 Check for possible leaks

" 500 5.2 -- Check coolers; clean if necessary

" 500 5.1 1 Remove air filters and inspect

Yearly 2000 4.3/4.4/4.7 8 When Atlas Copco HD Roto-injectfluid is used, change oil

" 4000 4.5/4.7 2 Replace oil filters

"---- 6 Carry out a LED/display test

"---- 5 Have all flexibles inspected

"--4.7/5.1 2 Replace air filters

"--5.3 7 Have safety valve tested

"---- -- Have the compressor inspected by an Atlas Copco Service

representative

"---- -- Have operation of sensors, electrical interlockings and components

tested by an electrician

Yearly 6000 -- 10 If an OSD separator is provided: replace filter below separator vessel

2-Yearly 8000 -- 3 Have oil separator element replaced

Loading...

Loading...