- 79 -

Technical specifications

TORQUE VALUES

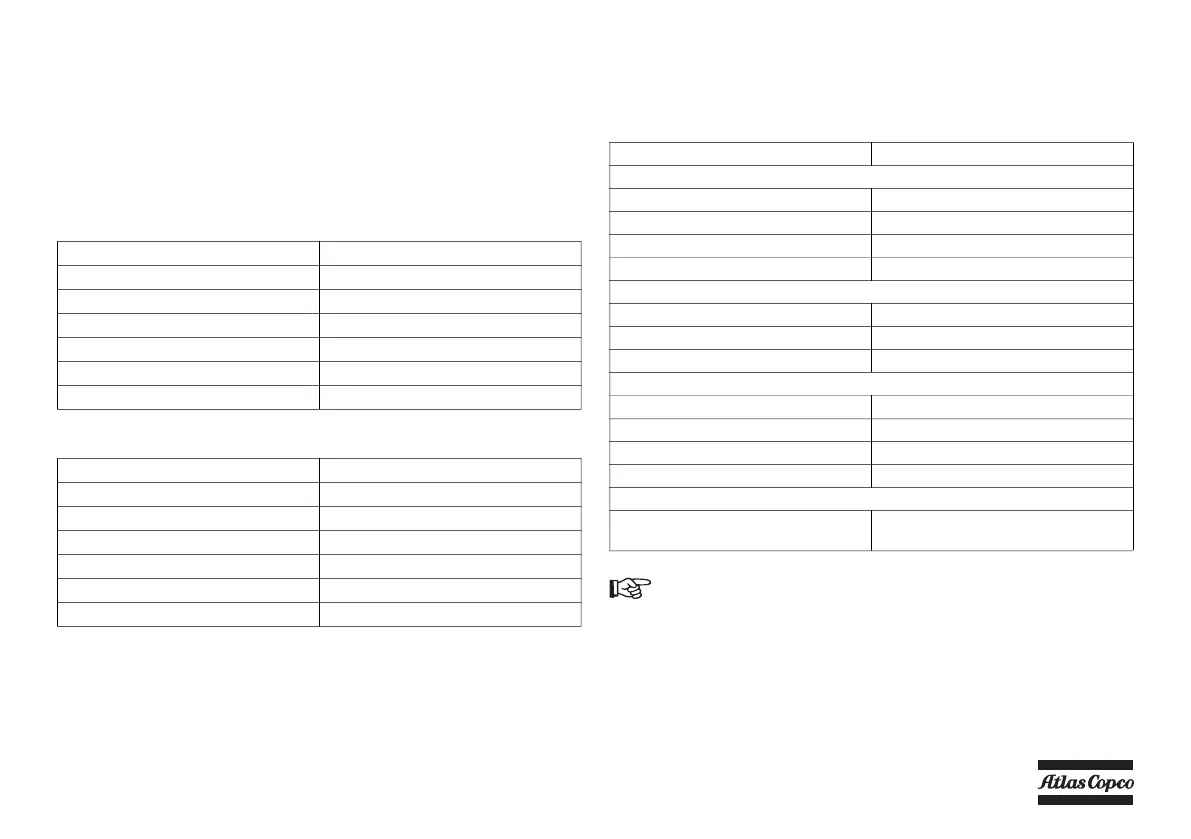

GENERAL TORQUE VALUES

The following tables list the recommended torques applied for general applications

during assembly of the compressor.

For hexagon screws and nuts with strength grade 8.8

For hexagon screws and nuts with strength grade 12.9

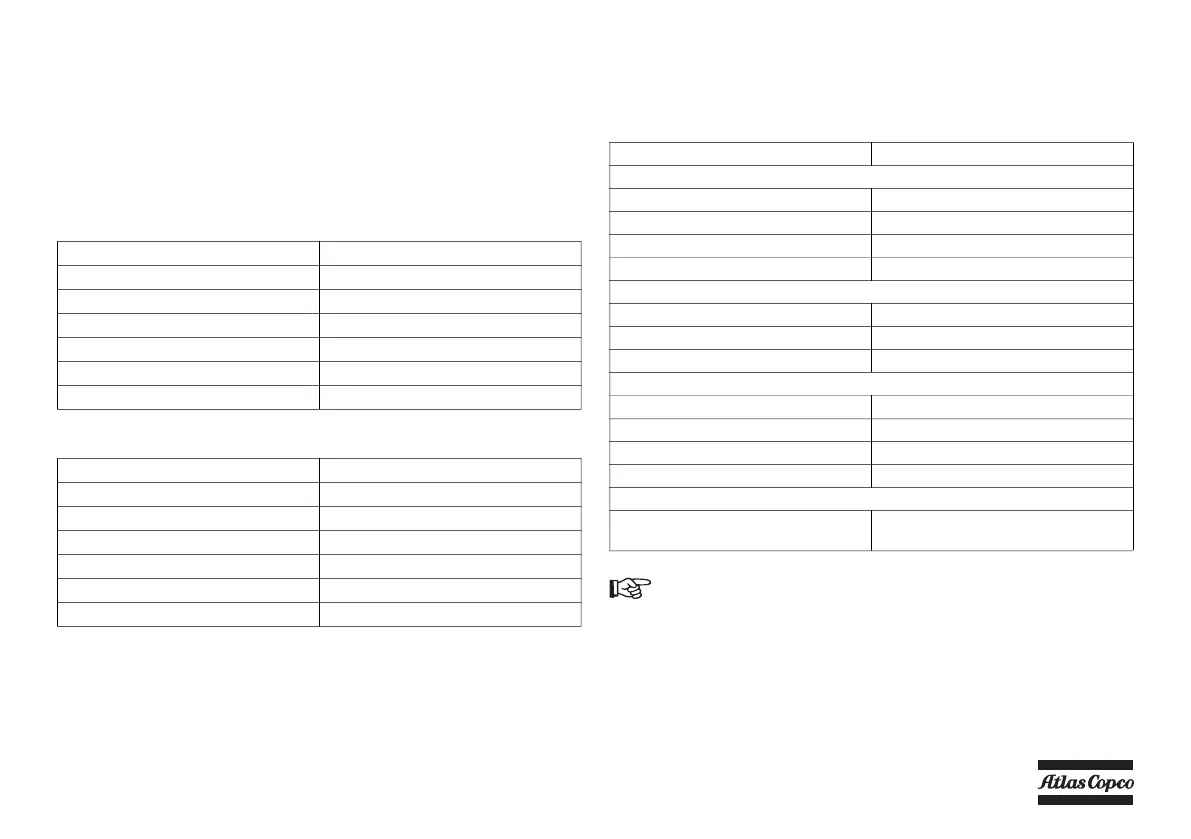

CRITICAL TORQUE VALUES

Thread size Torque value (Nm / lbf.ft)

M6 8 (6) +/-25 %

M8 20 (15) +/-25 %

M10 41 (30) +/-25 %

M12 73 (54) +/-25 %

M14 115 (85) +/-25 %

M16 185 (137) +/-25 %

Thread size Torque value (Nm / lbf.ft)

M6 14 (10) +/-21 %

M8 34 (25) +/-23 %

M10 70 (52) +/-24 %

M12 120 (89) +/-25 %

M14 195 (144) +/-23 %

M16 315 (233) +/-23 %

Assemblies Torque value (Nm / lbf.ft)

Compressor to frame:

Bolts, elements/gear casing 46 (33.95)

Bolts, elements/support 80 (59.04)

Bolts, support/buffer 205 (151.29)

Bolts, buffer/frame 80 (59.04)

Engine to frame:

Bolts, engine/support 205 (151.29)

Bolts, support/buffer 46 (33.95)

Bolts, buffer/frame 23 (16.97)

Lifting beams to frame:

Bolts, lifting beams/yoke (M12) 125 (92.25)

Bolts, lifting beams/yoke (M16) 205 (151.29)

Bolts, lifting beams/A-Frames 205 (151.29)

Bolts, A-Frames/frame 205 (151.29)

Hose clamps:

Pebra hose clamps on all IC/radiator

hoses

12 (8.85)

Secure the drain cock and tank cap of the fuel tank handtight.

Loading...

Loading...