9 / 22

Installation of gas circuit

The dregs like hydrocarbon and vapor contained in the cutting gas will damage the optical lens,

and fluctuate the power of gathered laser beam which will result in the differences of the cutting section

from the up to the bottom. Here are the suggested cutting gas and its purity (Figure 5). The higher the

gas purity is, the better the cutting quality of section will be.

The dregs can be filtered in the gas providing pipes while O2 and vapor can easily enter into the

optical system by permeating nonmetal parts, which is the reason why dust and hydrocarbon appear

inside the cutting head. So we kindly suggest you to use accessories in stainless steel and to use

purifier that can filter particulate minimum in 0.01 μm. And suggest you to use diaphragm pressure

gage in stainless steel, if you use diaphragm pressure gage in rubber, once the rubber aged, it can

easily react with the air inhaled by the industrial pressure gage and generate hydrocarbon. A230E

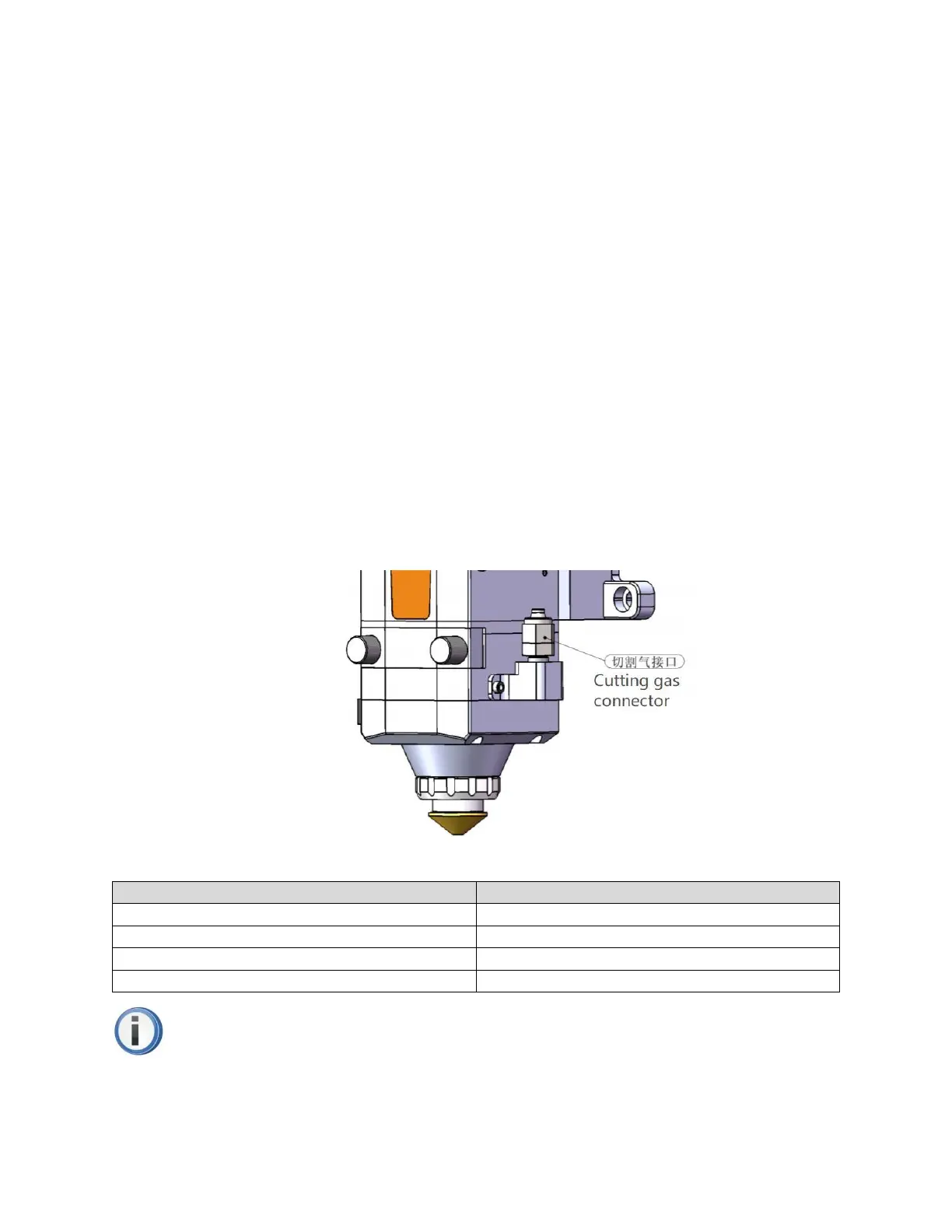

fiber laser cutting head has 1 cutting gas circuit, the outside diameter of gas pipe is 10mm. (Figure 5)

Figure 5. The interface of cutting gas of A230E electric fiber laser cutting head.

PS: Please don’t change the gas connector randomly, especially don’t use PTFE tape to

seal the gas connector or it may block the gas circuit thus affect the cutting quality and

damage the cutting head.

Loading...

Loading...