7. Electrical connection

.

Work on the electrical system or equipment must only be

carried out by a skilled electrician himself or by specially

instructed personnel under the control and supervision of

such an electrician and in accordance with the applicable

electrical engineering rules.

.

Installation regulations for Modbus must be observed for

the wiring.

(For literature references, please refer to appendix C)

Make sure to respect electromagnetic compatibility (EMC) when installing

cables:

Signal and bus cables are susceptible to interference.

Electric power cables are interference sources.

.

Lay cables being susceptible to inferference or sources of interference at

the highest possible distance from each other.

.

The interference immunity of signal and bus cables increases if the cables

are laid close to the ground potential.

.

Avoid long cables, if possible, or make sure that they are laid in locations

with low susceptibility to interference.

.

Avoid long parallel paths with cables being either interference sources or

susceptible to interference.

7.1 Power supply (standard) For explosion-proof version (type designation: AMExB/ AMExC), please

refer to page 15 or page 17.

.

Check whether type of current, supply voltage, and frequency comply with

motor data (refer to name plate at motor).

.

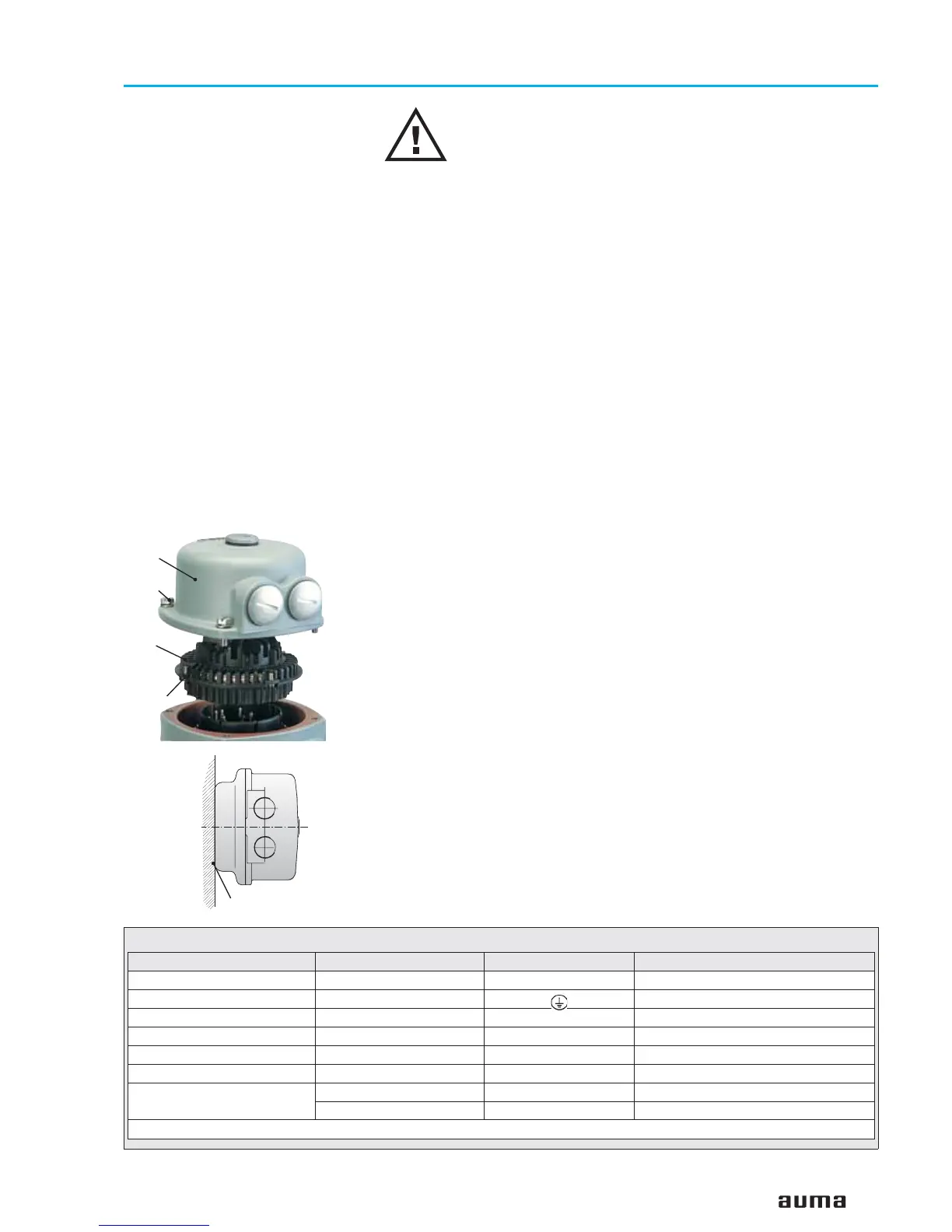

Loosen bolts (50.01) (figure B-1) and remove connection housing.

.

Loosen screws (51.01) and remove socket carrier (51.0) from plug cover

(50.0).

.

Insert cable glands suitable for connecting cables.

(The enclosure protection stated on the name plate is only ensured if suit-

able cable glands are used).

.

Seal cable entries which are not used with suitable plugs.

.

Connect cables according to order-related wiring diagram.

The wiring diagram applicable to the actuator is attached to the

handwheel in a weather-proof bag, together with the operation instruc-

tions. In case the wiring diagram is not available, it can be obtained from

AUMA (state commission no., refer to name plate) or downloaded directly

from the Internet (www.auma.com).

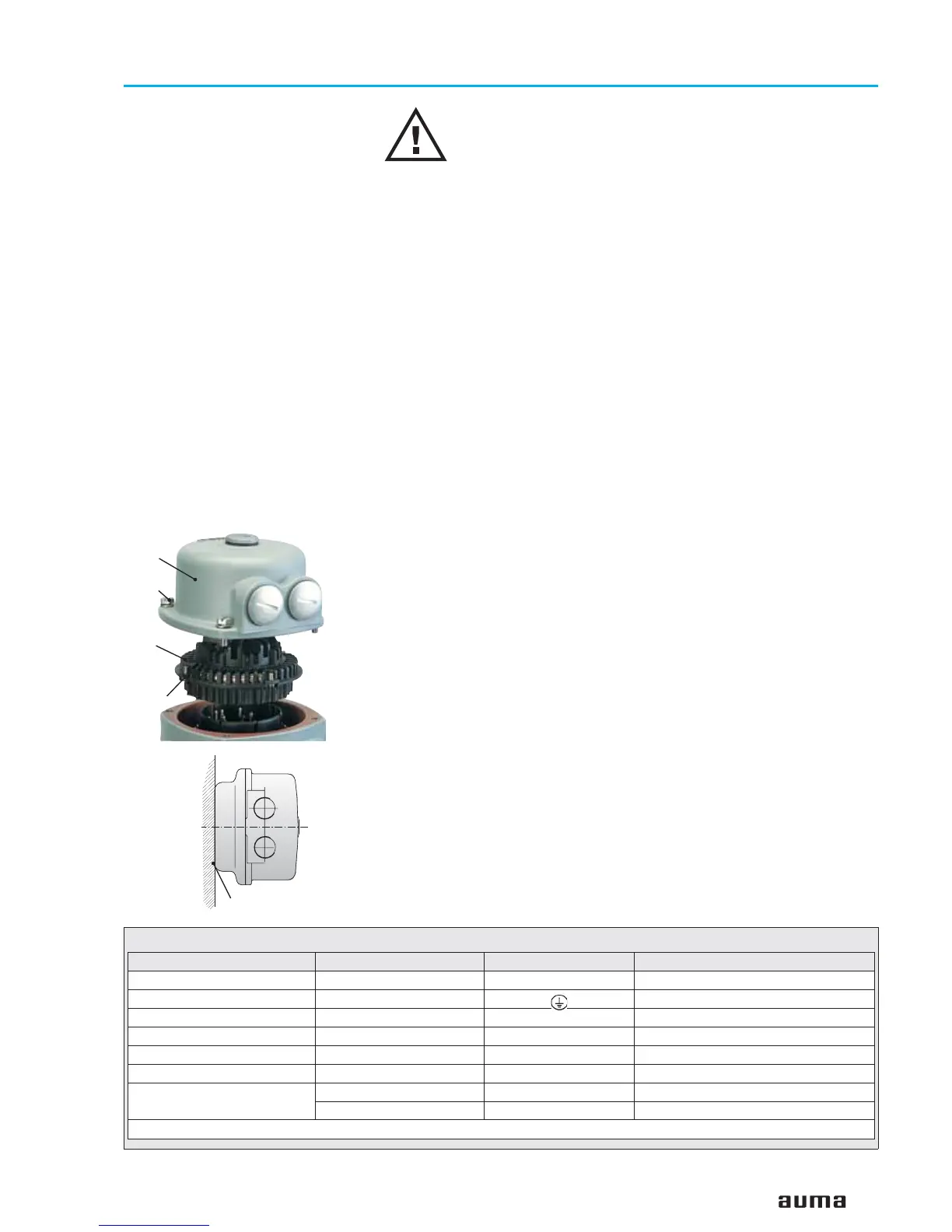

A special parking frame (figure B-2) for protection against touching the bare

contacts and against environmental influences, in case the electrical

connection has been removed, is available.

11

Actuator controls AUMA MATIC AM/ AMExB/ AMExC

Operation instructions Modbus

Figure B-1: Connection

50.0

50.01

51.0

51.01

Parking frame

Technical data Motor power connections

1)

Protective earth Control terminals

No. of contacts max. 6 (3 are used) 1 (leading contact) 50 pins / sockets

Marking U1, V1, W1, U2, V2, W2 1 to 50

Connecting voltage max. 750 V – 250 V

Nominal current max. 25 A –

16 A

Type of customer connection Screws Screw for ring lug Screws

Cross section max. 6 mm

2

6 mm

2

2.5 mm

2

Material: Pin/ socket carrier Polyamide

Polyamide Polyamide

Contacts Brass (Ms)

Brass (Ms)

Brass, tin plated or gold plated (option)

1)Suitable for copper wires. For aluminium wires, please contact AUMA

Table 2: Technical data AUMA plug/ socket connector for bus connection

Figure B-2: Parking frame (accessory)

Loading...

Loading...