2. Short description

Part-turn actuator

Definition in compliance with EN 15714-2/EN ISO 5211:

A part-turn actuator is an actuator which transmits a torque to the valve for less than

one full revolution. It need not be capable of withstanding thrust.

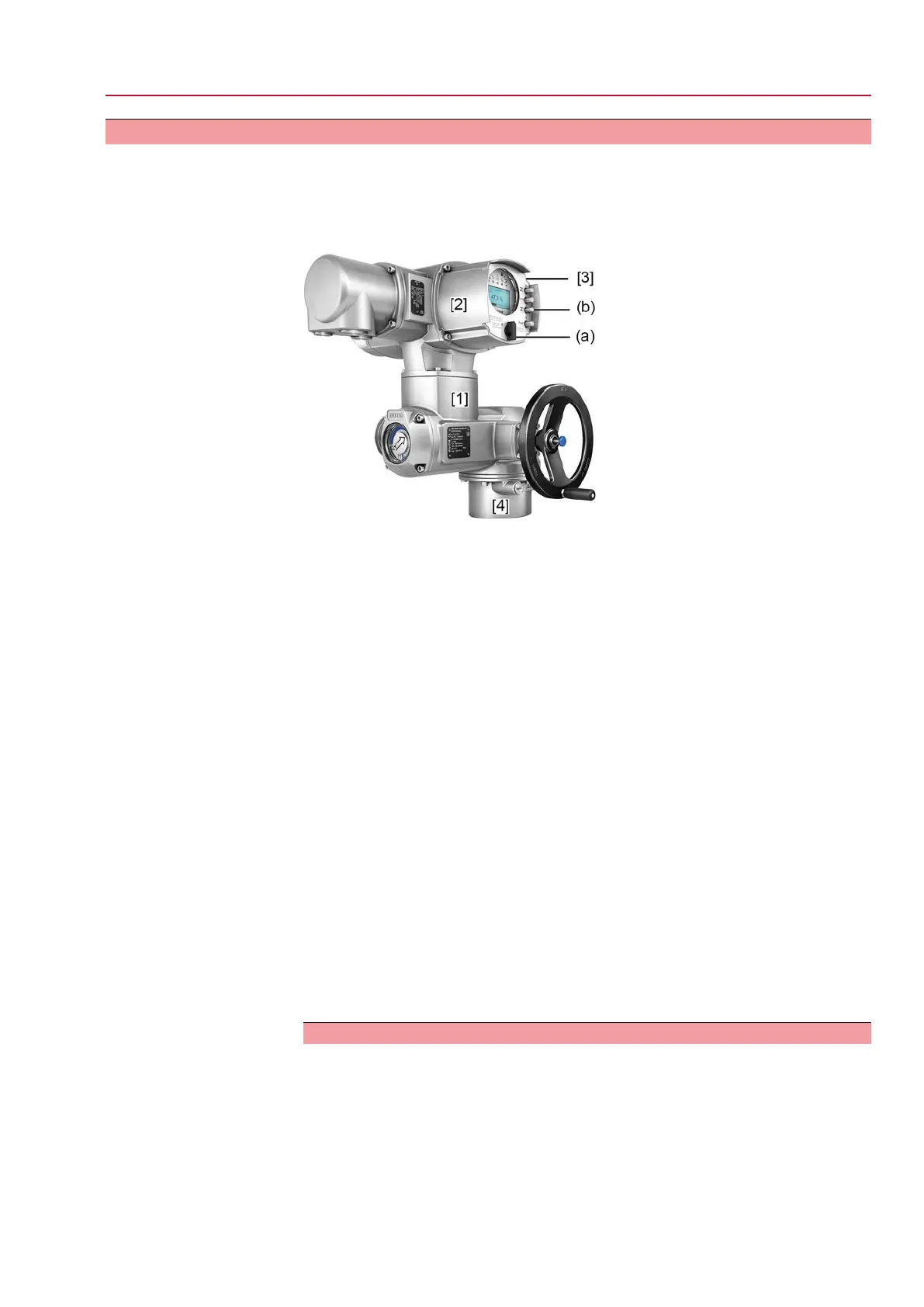

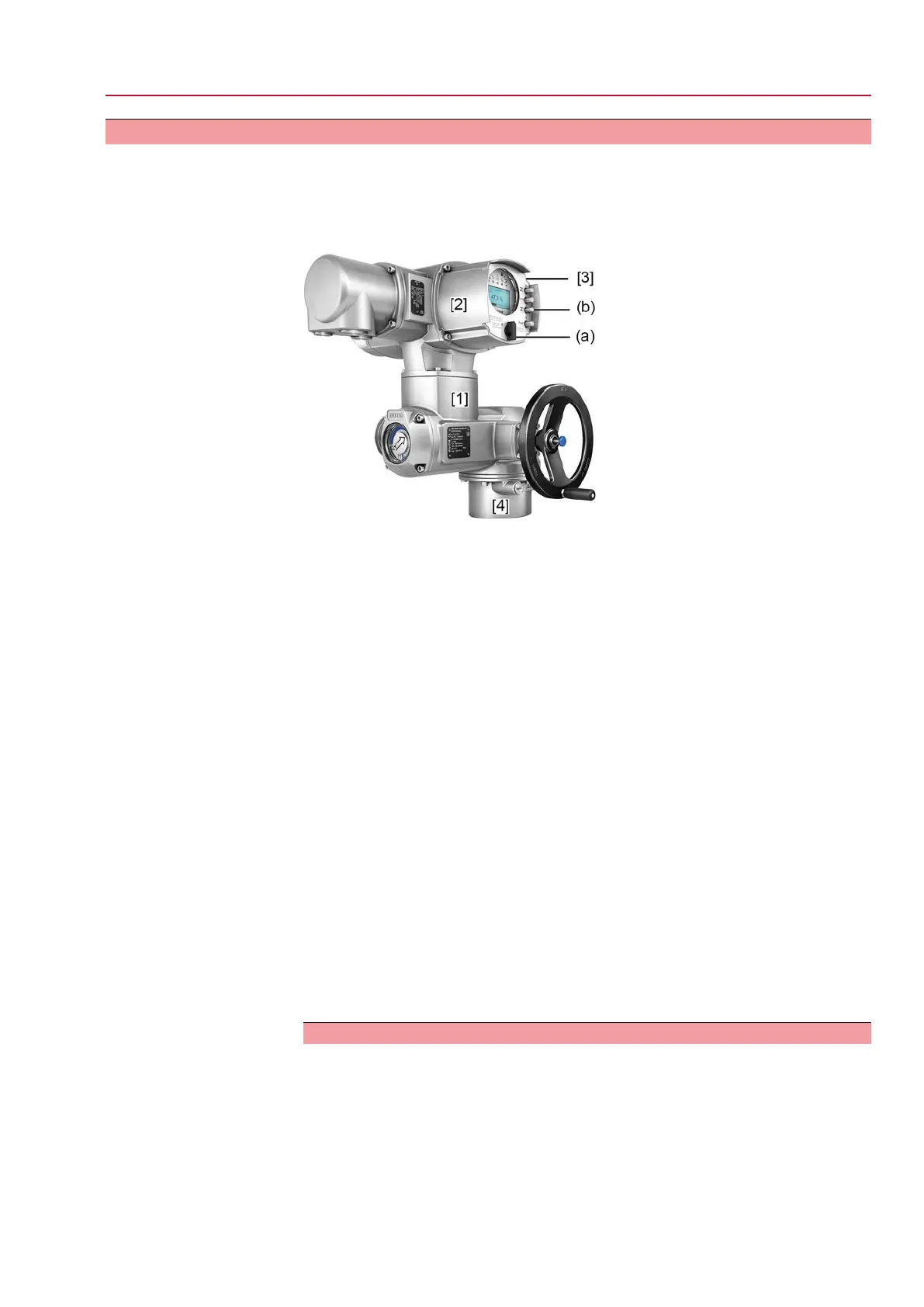

AUMA part-turn actuator Figure 1: AUMA SQ 10.2 part-turn actuator

[1] Part-turn actuator with motor and handwheel

[2] Actuator controls

[3] Local controls with display, (a) selector switch and (b) push button

[4] Valve attachment

AUMA part-turn actuators SQ 05.2 – SQ 14.2/SQR 05.2 – SQR 14.2 are driven by

an electric motor. For manual operation, a handwheel is provided. Switching off in

end positions may be either by limit or torque seating. Actuator controls are required

to operate or process the actuator signals.

For non-intrusive version (control unit: electromechanical version), limit and torque

setting is made via switches within the actuator.

For non-intrusive version (control unit: electronic version), limit and torque setting is

made via the actuator controls, neither actuator nor the actuator controls housing

have o be opened. For this purpose, the actuator is equipped with an MWG (magnetic

limit and torque transmitter), also capable of supplying analogue torque feedback

signals/torque indication and analogue position feedback signals/position indication

at the actuator controls output.

Actuator controls

The actuator controls AC 01.2 may be mounted directly to the actuator or separately

on a wall bracket.

The actuator can be operated via the push buttons on the local controls of the actuator

controls or settings can be made in the actuator controls menu.The display shows

information on the actuator as well as the menu settings.

The functions of actuator controls AC 01.2 include standard valve control in

OPEN-CLOSE duty, positioning, process control, logging of operating data right

through to diagnostic functions.

App and software

Using the AUMA CDT software for Windows-based computers (notebooks or tablets)

and the AUMA Assistant App, actuator data can be uploaded and read, settings

can be modified and stored.The connection between computer and AUMA actuator

is established wireless via Bluetooth interface. With the AUMA Cloud, we provide

an interactive platform to collect and assess e.g. detailed device data of all actuators

within a plant.

7

SQ 05.2 – SQ 14.2/SQR 05.2 – SQR 14.2 Control unit: electronic (MWG)

AC 01.2 Non-Intrusive Short description

Loading...

Loading...