24

CH100

M12X30

M12 DIN 315

EMPTYING THE CHIPPER AFTER USE

Let the chipper run empty by operating it for a short

time.

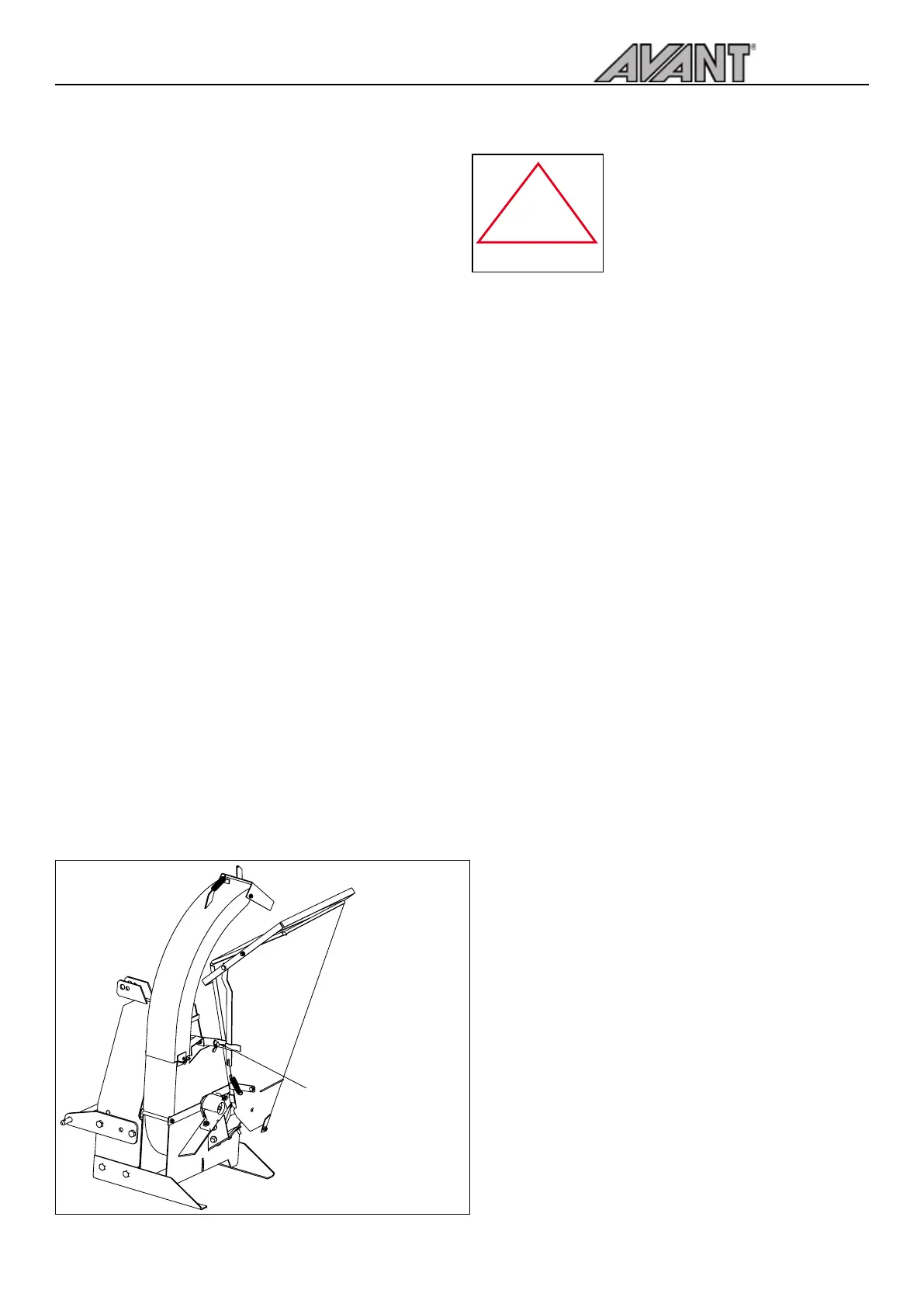

SWIVELING THE FEED HOPPER TO THE TRANSPORT

POSITION

1. Attach the feed hopper to the chipper using an

M12x30 hexagon head bolt and an M12 buttery

nut. See the gure showing how the feed hopper

is swiveled to the transport position.

STORAGE OF THE CHIPPER

• Before detaching the chipper from the tractor,

park it on level and hard ground. Take appropriate

measures to prevent the chipper from moving or

falling.

• If the chipper is to be stored for a long period,

lubricate the knives e.g. with petroleum jelly.

• Take appropriate measures to keep the water

drainage holes on the lower chamber open.

Fig 6. Swiveling the feed hopper to the transport position

Screw

Buttery nut

MAINTENANCE

Before beginning maintenance

and repair

• place the chipper onto level and hard ground and

make sure it cannot tip;

• turn o the loader.

• disconnect the hydraulic hoses from the loader.

• familiarize yourself with the machine-specic

maintenance and repair instructions.

In case of doubt, please contact the manufacturer.

• Always lock the rotor before adjusting or changing

the knives.

• Always wear protective gloves when handling

knives.

PERIODIC INSPECTIONS

• With new machines, check the mounting bolts for

tightness after the rst operating hour, tightening

them if necessary. Tightening torques are shown

in table.

• Check the mounting bolts for tightness once a

week.

• The knife-to-anvil clearance is adjusted to the

specied values. For instructions on adjusting

the clearance, For instructions on adjusting

the clearance, see Adjusting the knife-to-anvil

clearance.

WARNING!

!

Loading...

Loading...