5-4

5-3. Cleaning the flapper

If contamination from the instrumentation air has accumulated on the flapper, clean the

flapper as described below.

CAUTION

If air pressure is supplied to the SVP, the nozzle back pressure may change causing the valve

position may change suddenly when the flapper is cleaned. Only clean the flapper in a state

where no one will be injured and plant operation will not be adversely influenced even if the

valve moves suddenly.

Procedure

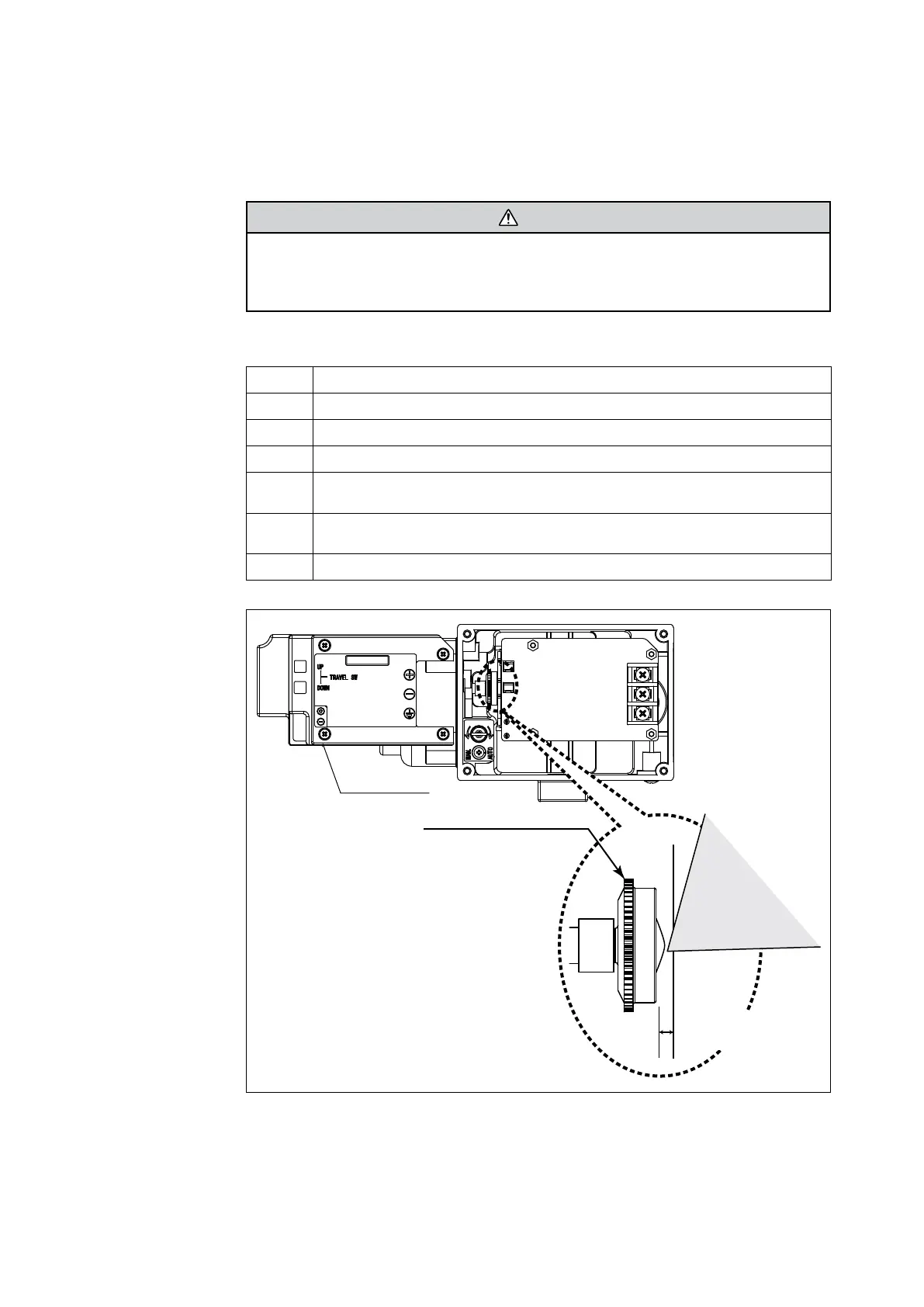

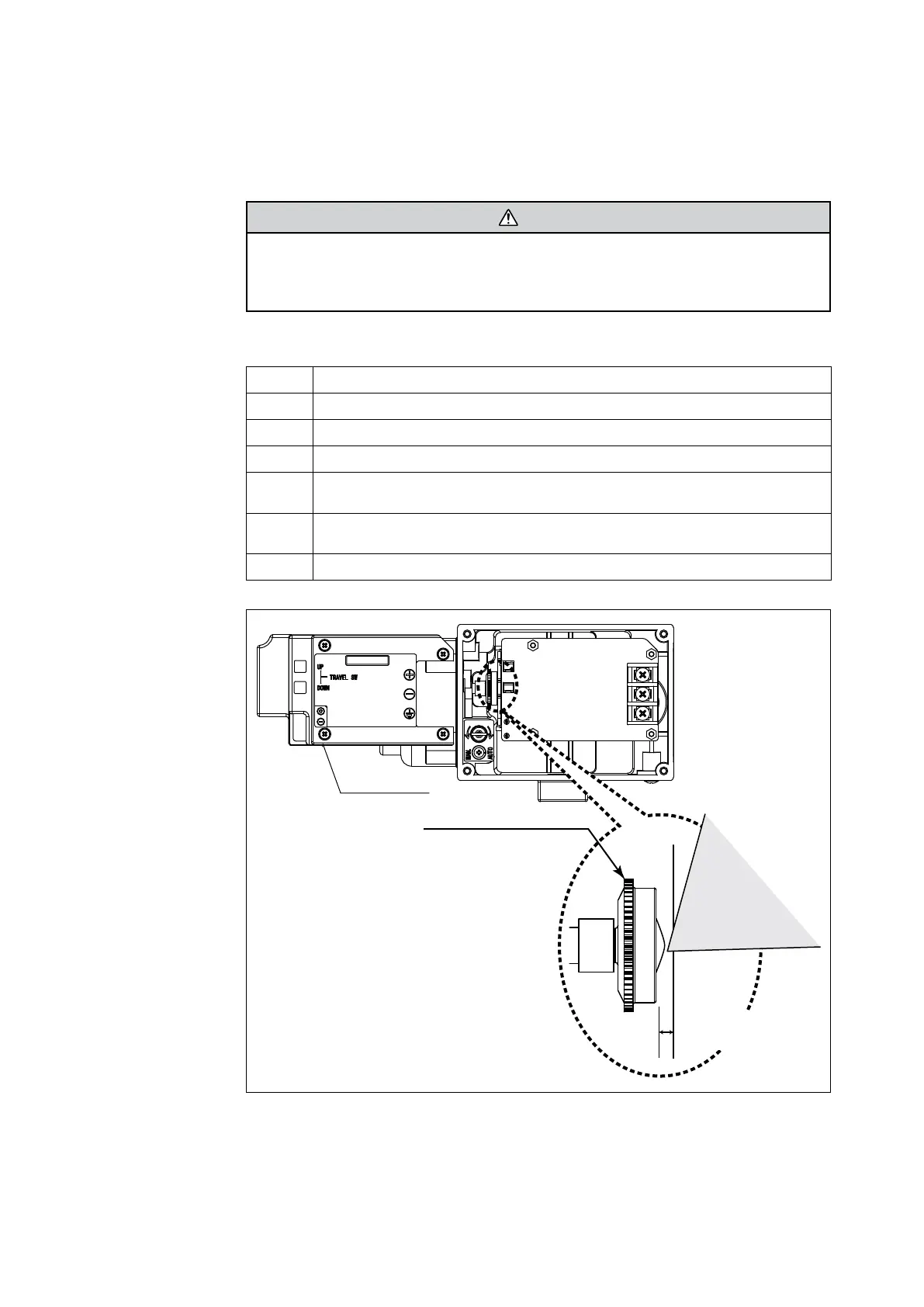

Step No. Procedure

1 Remove the cover.

2 Remove four screws from the cover plate.

3 Remove the plate by sliding it to the left.

4

Provide pieces of paper with a thickness of 0.2 mm. Standard business cards will

do.

5

Use the scraps of paper to clean the contamination from the gap between the

EPM nozzle and the flapper.

6 After cleaning the gap, reassemble the plate and cover.

Cover plate

EPM adjustment screw

Business card

Approx.

0.2 mm

Fig. 5-5. EPM balance adjustment

Loading...

Loading...