5-5

5-4. EPM (Electro-pneumatic converter module) balance adjustment

In situations such as when excessive mechanical shocks and other external disturbances

have been applied to the SVP itself, or when contamination from the instrumentation air has

collected in the nozzle flapper area, the internal EPM (electropneumatic converter module)

balance point may be displaced and the response characteristics degraded. This can lead to

malfunctions occurring. If the balance point displacement cannot be rectified by cleaning the

nozzle flapper area, EPM adjustment will be necessary.

CAUTION

The EPM balance adjustment can cause the valve position to change rapidly. Only perform

this adjustment in a state where no one will be injured and plant operation will not be

adversely influenced even if the valve moves suddenly.

Procedure

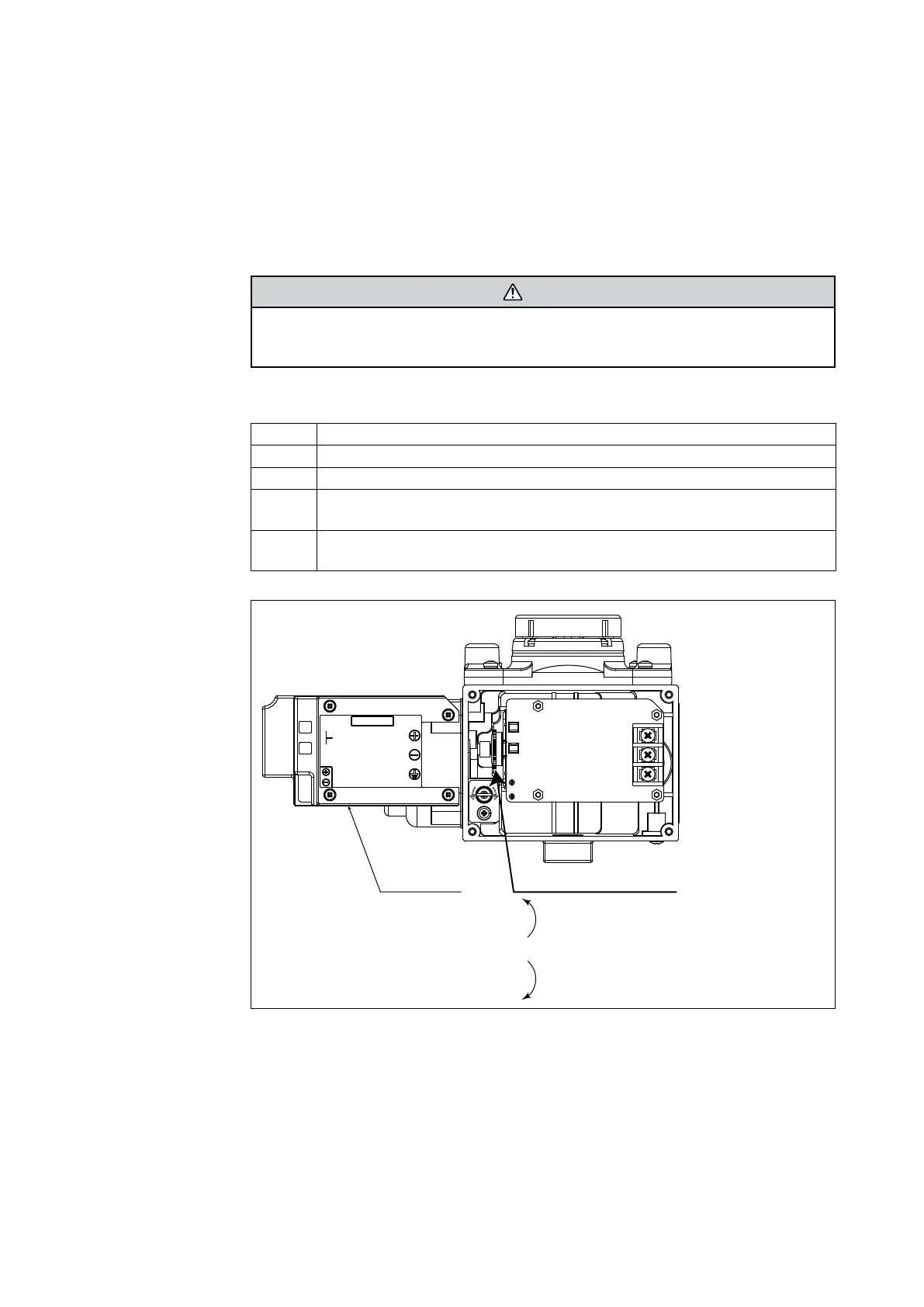

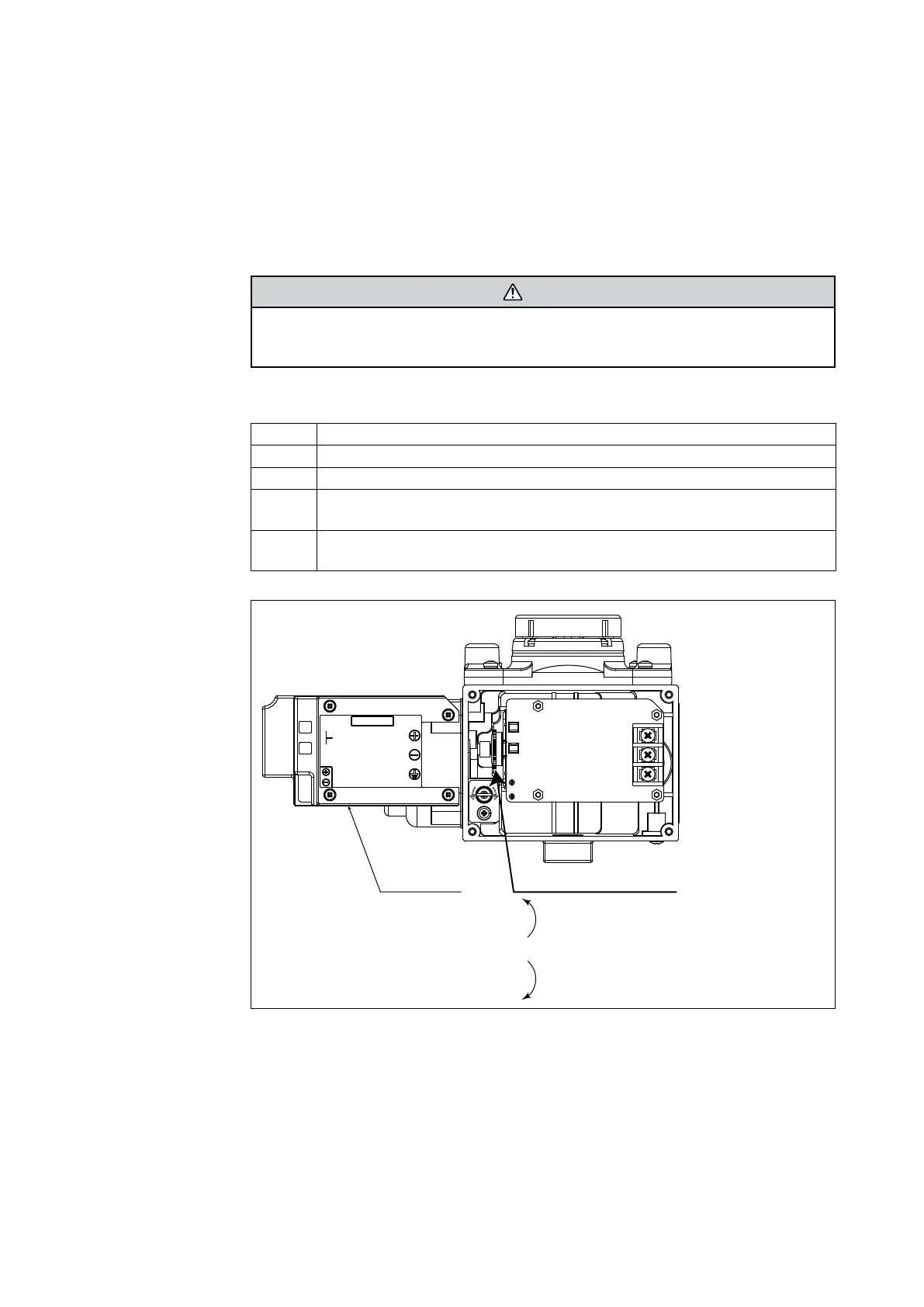

Step No. Procedure

1 Remove the cover and the cover plate.

2 After supplying the stipulated air pressure, set the input signal to 50%.

3

Observe the EPM drive signal using the Commstaff. (Refer to “4-6-4. Dummy

Drive Signal” on page 4-19)

4

Adjust the EPM drive signal to have a 50% ±5% duty by turning the EPM

adjustment screw.

Cover plate

EPM adjustment screw

Turning this screw in the counterclockwise

direction increases the EPM drive signal (duty value).

Turning this screw in the clockwise direction

decreases the EPM drive signal (duty value).

AUTO

MAN.

DOWN

UP

TRAVEL SW

Fig. 5-6. EPM balance adjustment

Loading...

Loading...