Page 18/37

Operating Instructions BA 373-E66

Technical specifications subject to change

W. Bälz & Sohn GmbH & Co. Koepffstrasse 5 74076 Heilbronn Germany

Phone +49 (0)7131 15 00 0 Fax +49 (0)7131 15 00 21 www.baelz.de mail@baelz.de

Observe copyright protection DIN 34

7. POSITIONING ELECTRONICS

7.1 Operating principle of the positioning electronics

The positioning electronics is designed for the control and positioning of actuators. By applying a continuous input

signal, the positioner moves the actuator to the dened position. To do so, the positioner compares the controlled

variable (actual value) and the reference variable (set point). If these two values deviate, the positioner issues a

voltage signal (manipulated variable) to control the valve until the set point and the actual value are within a toler-

ance band. To determine the set point, a potentiometer to record the actuator's travel movement is required in the

actuator. The LEDs on the positioner board indicate the status of the positioning electronics.

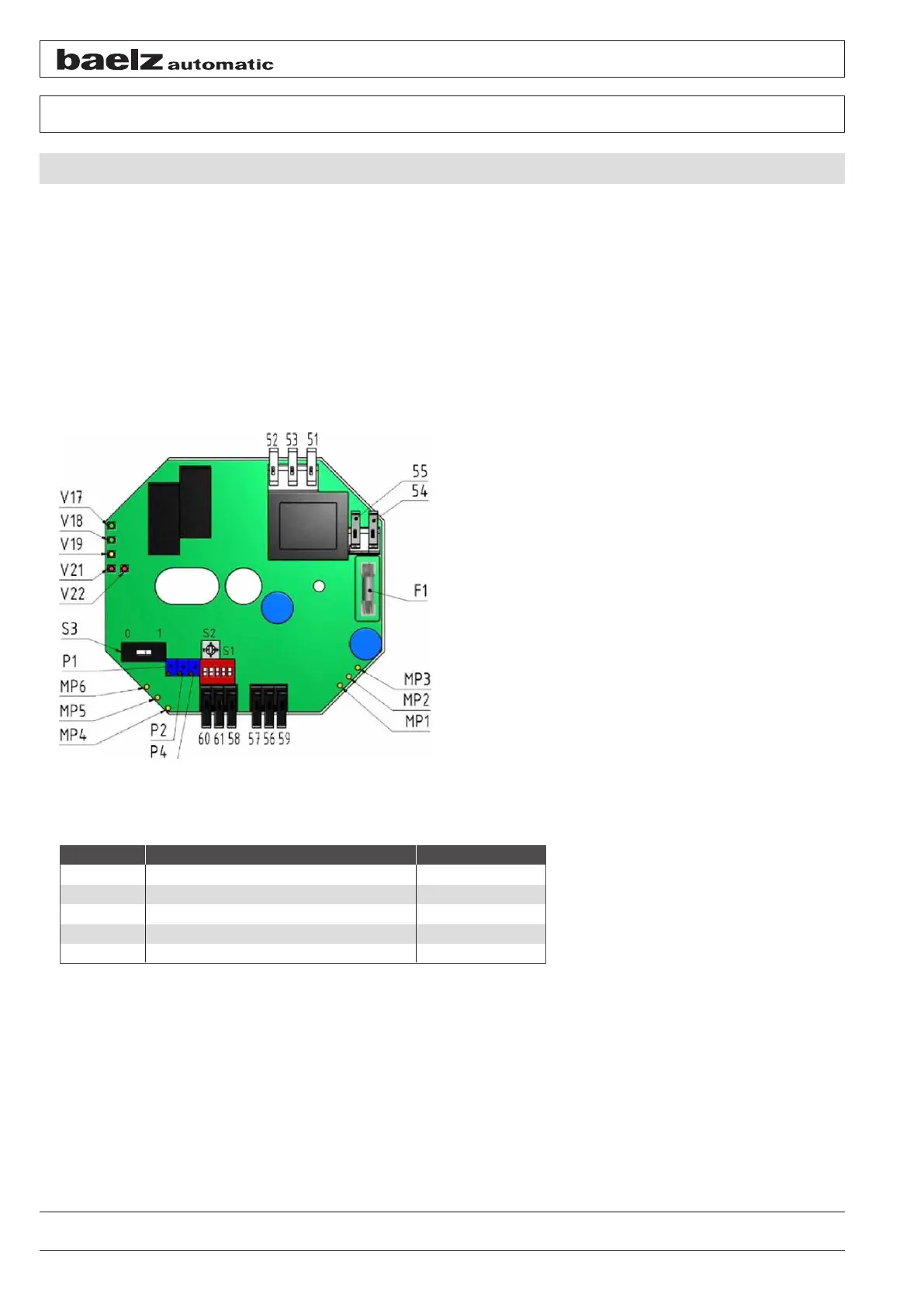

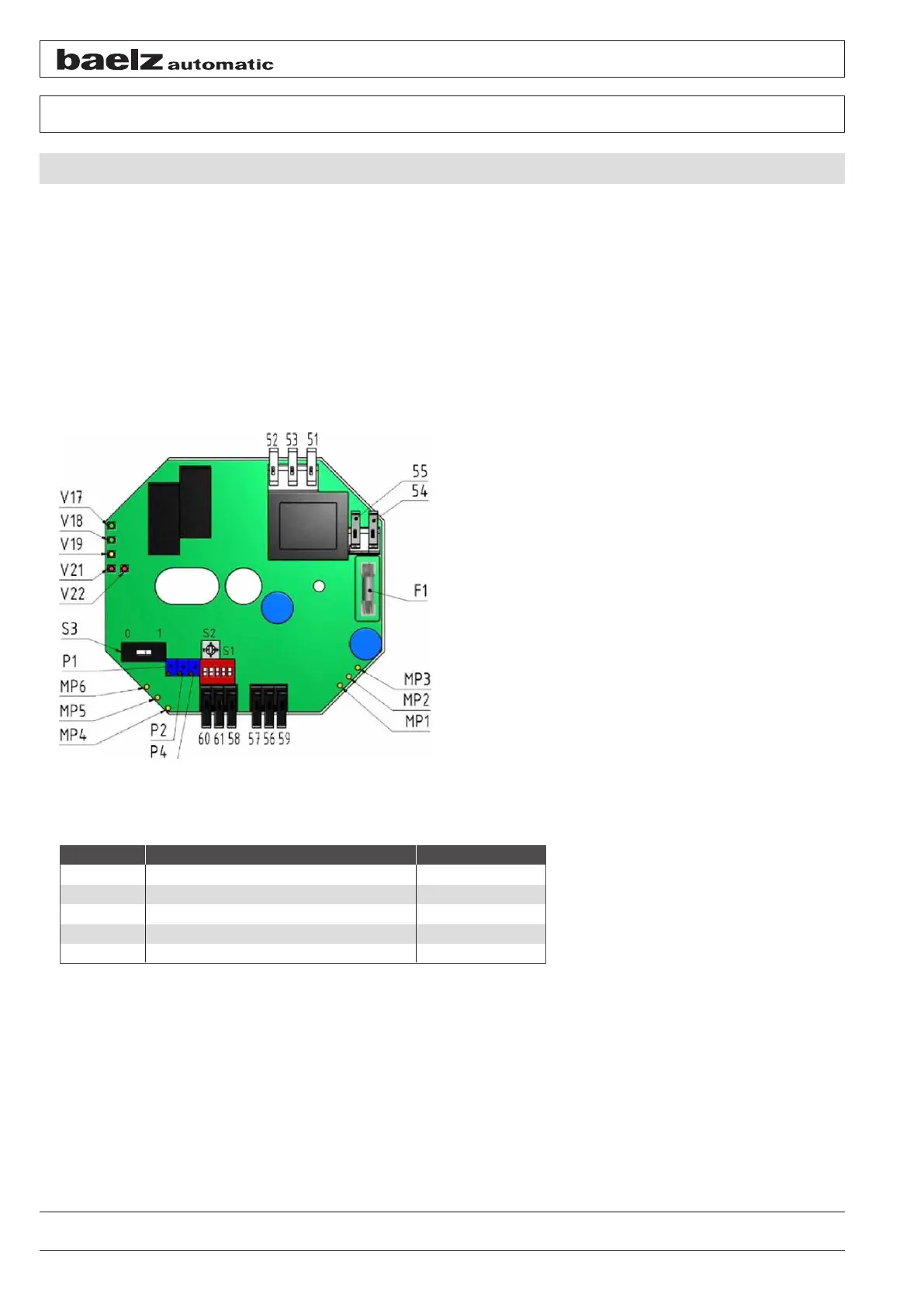

Figure 15: Positioning electronics

Use potentiometers P1, P2 and P4 as well as selector switches S2 and S3 to adjust settings, e.g. stroke calibra-

tion, split-range operation, reversed actuator action and dead band. The DIP switch settings of switch S1 allow

additional functions to be adjusted (e.g. preset zero, spreading of the potentiometer signal and behaviour upon

signal failure). The positioner comes with a minimum dead band of 200 ms to prevent sudden changes of the

actuator action or rapid activation and deactivation of the actuator. By default, the positioner has a feedback signal

that returns the current position of the valve. The signal range corresponds to the input signal range. The feedback

signal is not isolated from the input. The type of the control signal (voltage or current) is determined by the termi-

nal assignment.

LED Meaning Indicator

V17 Supply voltage ok green

V18 Actuator spindle retracts green

V19 Actuator spindle extends green

V21 Dead band active red

V22 E1 < 4 mA red

Loading...

Loading...