Bandit

Copyright 11/10 PAGE 28

MODEL 490 MAINTENANCE SECTION

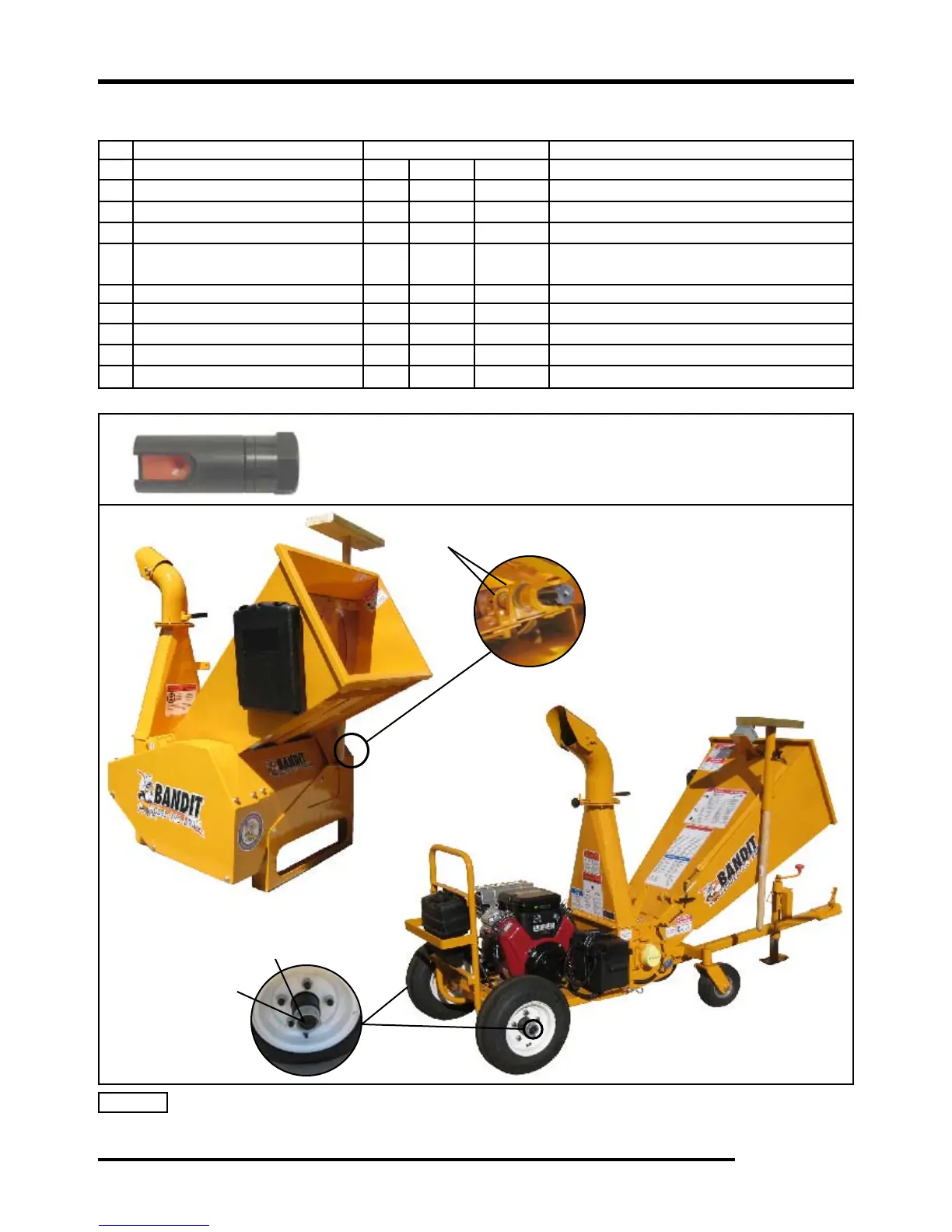

LUBRICATION CHART

NOTICE Use as a reference only, locations may vary depending on options or component manufacturer.

Lubrication point instructions are described on the machine, in the Lubrication & Coolant Section

and Maintenance Section of this manual, or component manufacturer’s manual.

CHECK

# DESCRIPTION DAY WEEK MONTH PROCEDURE

1 Drum Bearings X Purge bearings daily - wipe off excess

2 Jack Shaft Bearings (PTO) X Purge bearings daily - wipe off excess

3 Infeed Hopper Hinge X Lubricate

4 Steel Friction Areas: pivoting, X Lubricate (i.e. castor wheel mount bar,

hinged, sliding, rolling discharge ipper, etc)

5 Castor Wheel Pivot Bushings X 1 to 2 shots of grease - wipe off excess

6 Wheel Bushings X 1 to 2 shots of grease - wipe off excess

7 Wheel Bearings (Towable) X Grease until full - wipe off excess

8 Discharge Swivel Plates 3 Months Grease as needed

9 Wheel Bearings (Towable) Yearly Purge yearly - wipe off excess

A right angle grease tting may need to be used to grease

some of the lubrication points. This type of grease tting

can be obtained from most local automotive parts stores.

2

9

7

Loading...

Loading...