P/N 43298 rev. E 13

Banner Engineering Corp. •Minneapolis,MNU.S.A.

www.bannerengineering.com•Tel:763.544.3164

MINI-ARRAY

®

InstructionManual

Installation and Mechanical Alignment

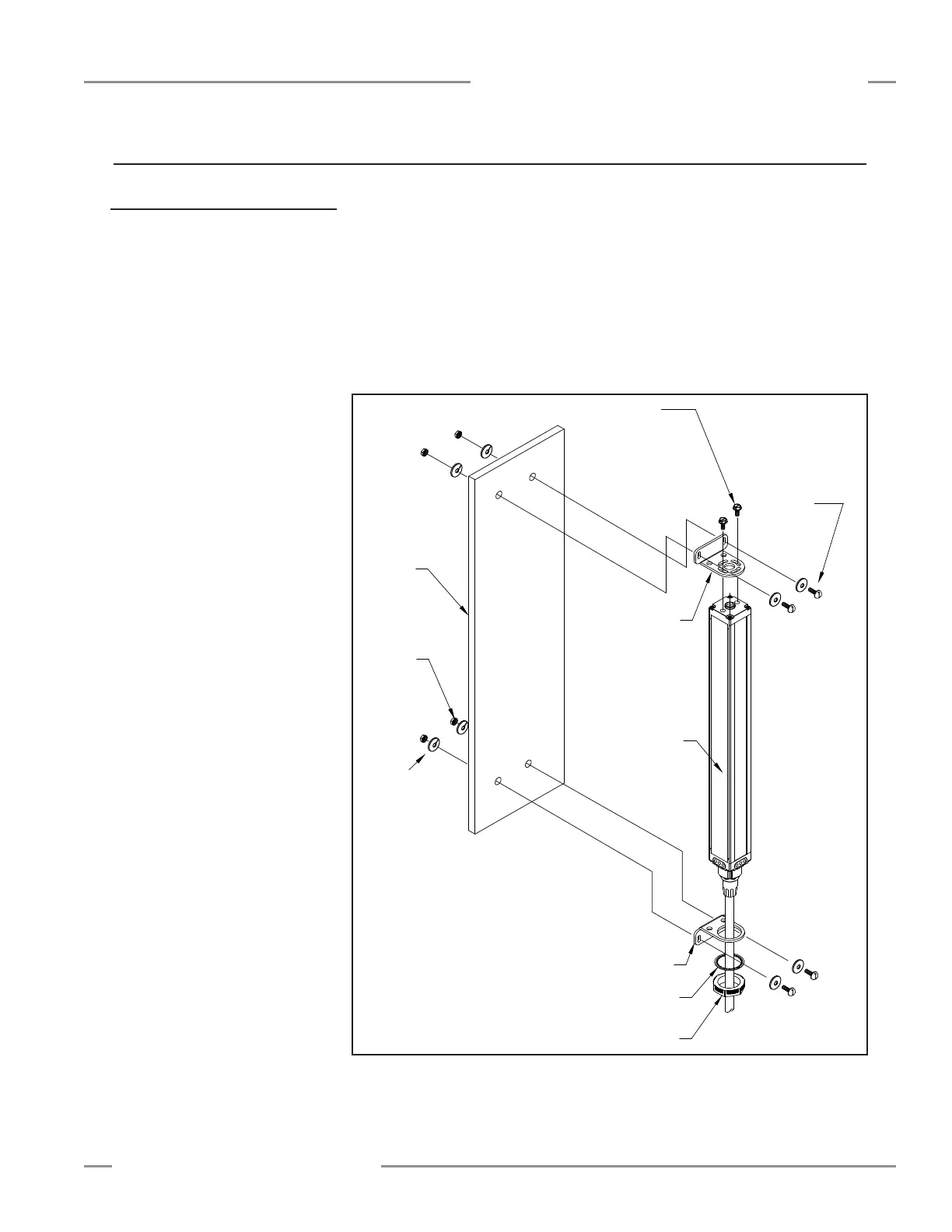

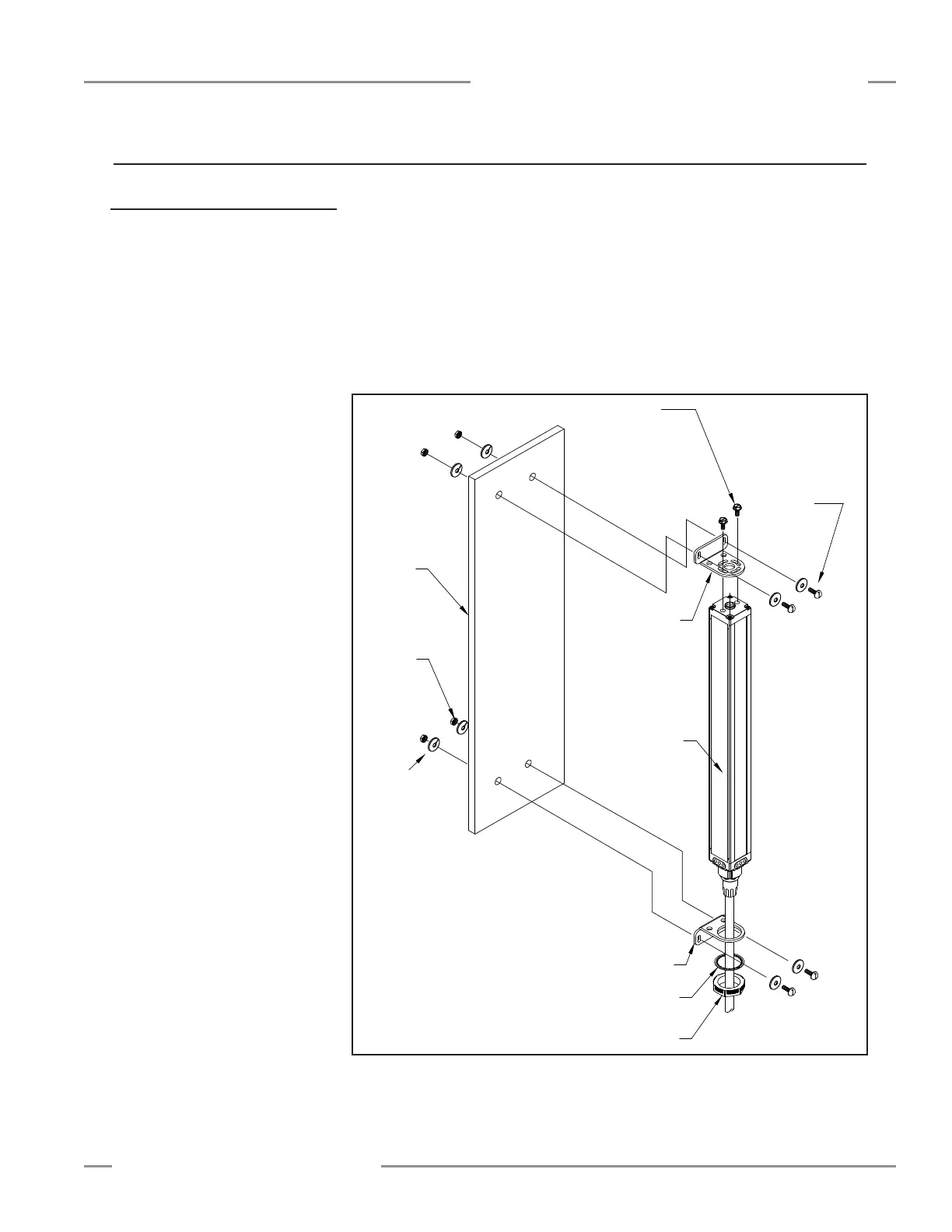

3.1 Emitter and Receiver Mounting

BannerMINI-ARRAYemittersandreceiversaresmall,lightweight,andeasytomount;themountingbrackets(supplied)allow±30

degreesrotation.

Fromacommonpointofreference,makemeasurementstopositiontheemitterandreceiverinthesameplanewiththeir

midpointsdirectlyoppositeeachother.MounttheemitterandreceiverbracketsusingtheM4x0.7x14mmboltsandassociated

mountinghardware(allsupplied).SeeFigure3-1.

Althoughtheinternalcircuitryoftheemitterandreceivercanwithstandheavyimpulseforces,vibrationisolatorscanbeused

insteadoftheM4boltstodampenimpulseforcesandpreventpossibledamagefromresonantvibrationoftheemitterorreceiver

assembly.TwodifferentAnti-VibrationMountingKitsareavailablefromBannerasaccessories.

Figure 3-1. MINI-ARRAY emitter and receiver mounting hardware

Emitter

or

Receiver

Mounting

Mounting

Bracket

Surface

M4

Nut (4)

Washer (2)

with Compression

Slotted Hex Head

M4 x 10 mm

Bracket

Mounting

Nut

Washer

M4 x 14 mm

Screw with Flat

Washer

Compression

Washer (4)

Torque to

12 in. lbs.

(1.3 N-m)

3. Installation and Mechanical Alignment

P/N48955consistsof4anti-vibration

mounts(M4x0.7x9.5mm)and8

M4Kepsnuts.Thesemountsaremade

fromBUNA-Nrubberandaremore

resistanttochemicalsandoils.

P/N12847consistsof4anti-vibration

mounts(M4x0.7x9.5mm)and8

M4Kepsnuts.Thesemountsaremade

fromnaturalrubber,whichareless

chemicallyresistantthanthe48955

mounts,buthaveagreatersheerforce

specathighertemperature.

Loading...

Loading...