Manual 2100-671C

Page 18 of 59

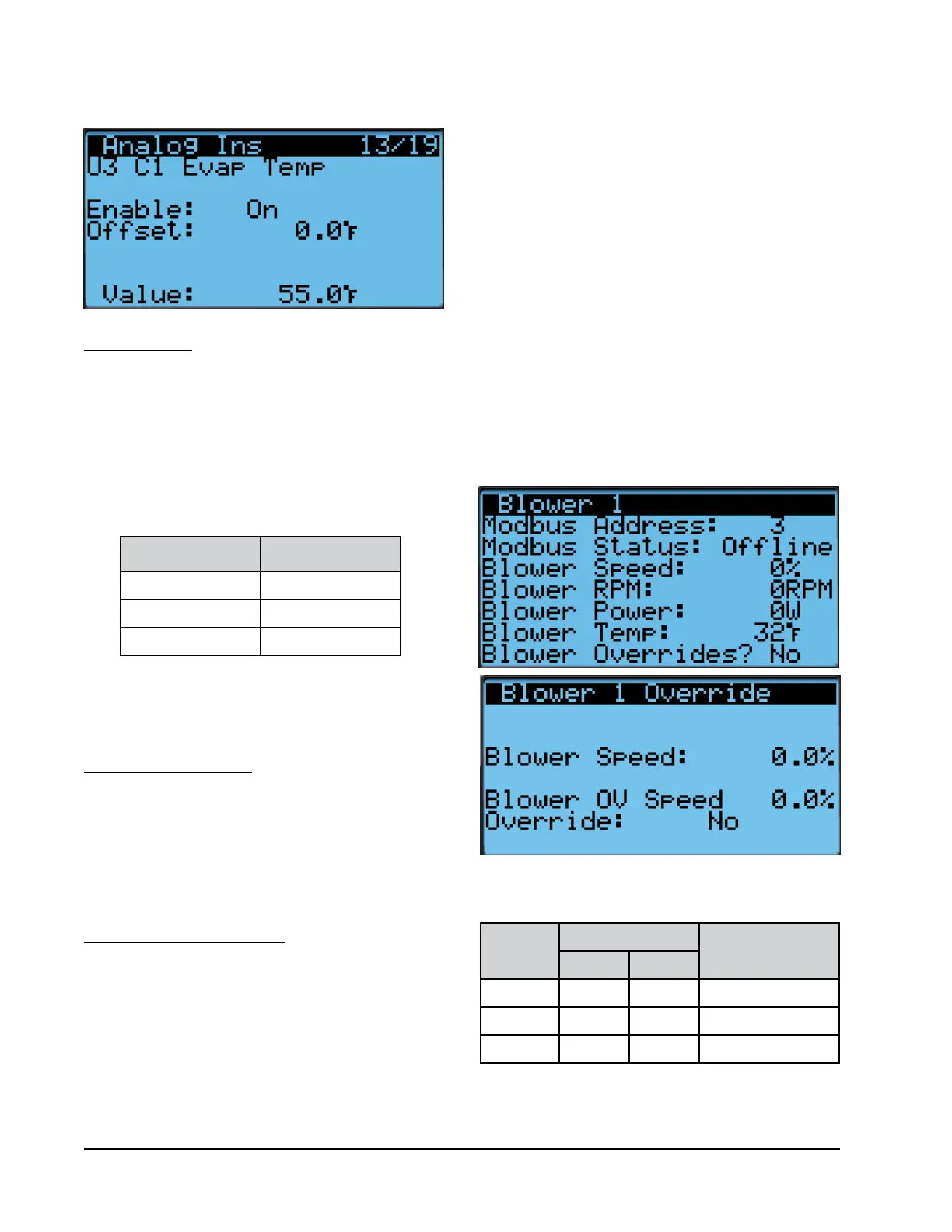

To put the blower into override:

1. Press MENU key to go to the Main Menu screen.

2. Press UP or DOWN keys and ENTER key to enter

TECHNICIAN password 1313.

3. Press UP or DOWN keys to scroll to I/O Config;

press ENTER key.

4. Press UP or DOWN keys to scroll to Fans / Blowers;

press ENTER key.

5. Press UP or DOWN keys to scroll to Blower 1.

6. Press ENTER key to scroll to Blower Overrides?

(see Figure 23).

7. Press UP or DOWN key to change No to Go. The

override will begin and the screen will change to

the override screen (see Figure 23).

The override will last for 5 minutes or until the Blower

Overrides parameter is set to No again.

EEV Operation

EEV Superheat Control

The electronic expansion valve (EEV) will open or

close to maintain the superheat setpoint while the

compressor is running (see Table 4). When the

compressor is not running, the valve will close to the

20% open default position.

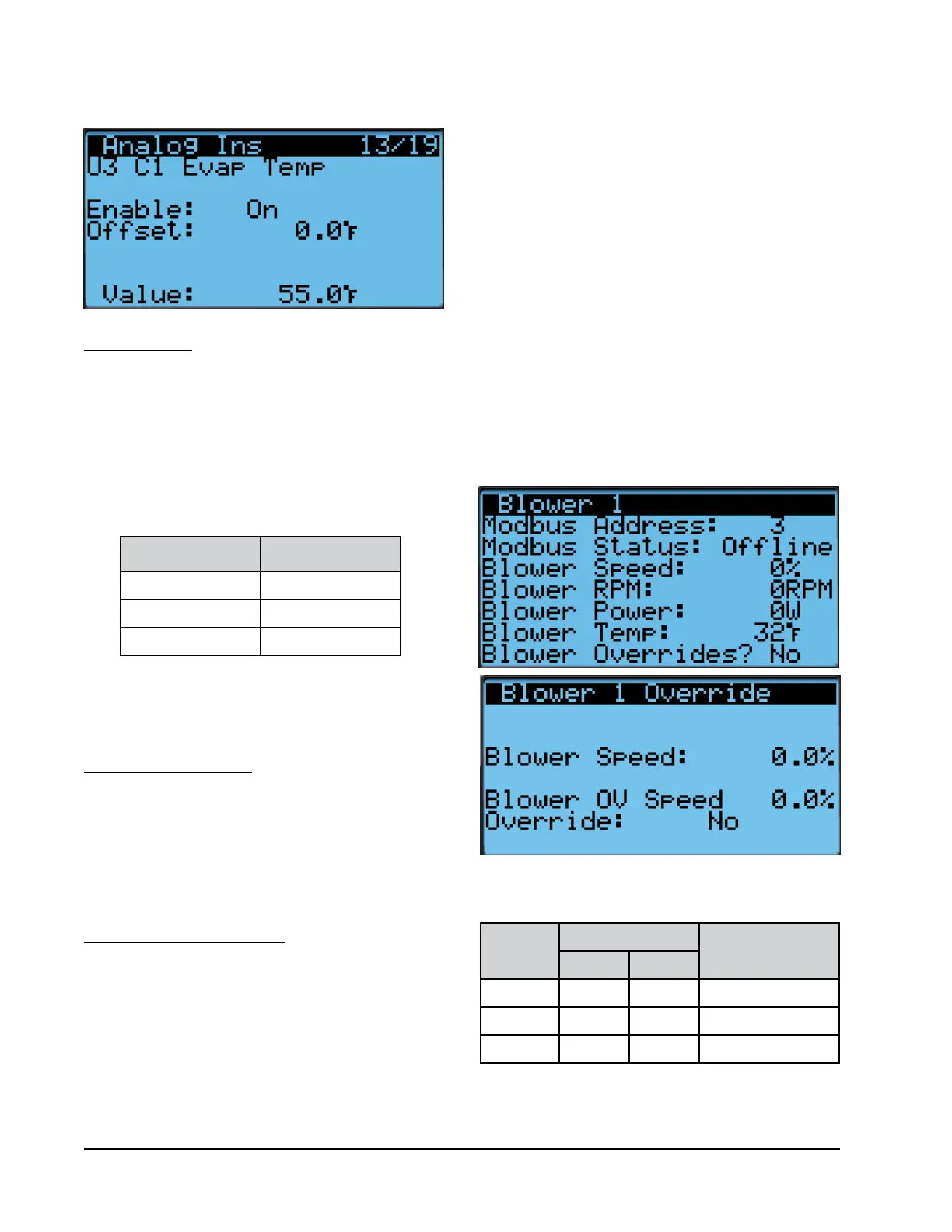

FIGURE 22

Adjusting Evaporator Freeze Sensor Values

FIGURE 23

Putting Blower Output into Override Mode

TABLE 5

Rated Airflow

Nominal Rated CFM

Nominal Rated ESP

High Low

W090A 3000 2100 0.25

W120A 4000 2800 0.30

W150A 4600 2800 0.35

TABLE 4

Unit Specific Superheat Setpoints

Unit Superheat

W090A 14°F

W120A 10°F

W150A 14°F

Low superheat protection will be active once the

superheat value is at or below 5°F. At this point,

the control will aggressively close the valve so that

superheat is maintained.

Additional EEV Alarms

Low Superheat Alarm

This alarm will become active when the calculated

superheat goes below 5°F. This alarm will clear itself

when the condition is no longer present.

This alarm cannot be adjusted.

Indoor Airflow

Indoor Airflow Components

Blower

The unit is equipped with a blower that is driven by an

electronically commutated motor (ECM). The blower

is controlled by a 0-100% signal through Modbus

communication. The motor controller converts this

signal to a PWM signal. The blower uses a 22" (560

mm) diameter wheel and operates up to 1500 rpm.

The blower output can be put into an override mode for

verification or troubleshooting.

Loading...

Loading...