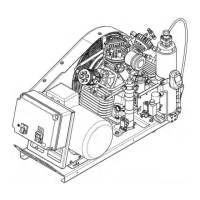

G 120 II V

Page 64 1st Edition, Rev. 0 Chg. 2

4.2.2 Component Description

4.2.2.1 Oil & Water (condensate) Separator

The air leaving the final stage is cooled in the aftercooler to approximately 18 - 27° F (10 -15° C) above

ambient temperature and then enters the oil and water separator. The oil and water separator works by

means of a sintered metal filter which separates liquid oil and water particles from the compressed air.

^ WARNING

The rapid depressurizing and repressurizing of the oil and water separator during condensate draining sub-

jects it to metallurgical stresses. To prevent catastrophic failure with the possibility of damage, injury or

death the oil and water separator (P/N 079416) must be replaced after a predetermined number of cycles.

One load cycle equals one pressurization plus one depressurization.

Units operating between 3,000 and 5,000 psi = 130,000 load cycles (32,500 hours of operation)

Units operating between 5,000 and 6,000 psi = 55,000 load cycles (13,750 hours of operation

The Bauer recommended frequency of condensate draining is every fifteen minutes and is a balance

between maximizing the life of the separator chamber and maintaining the quality of the delivered air.

Figure 4-7 Oil and Water Separator

Loading...

Loading...