TAM 00682 18

DSC 045-100 07 / 2012

Three-phase synchronous motor English

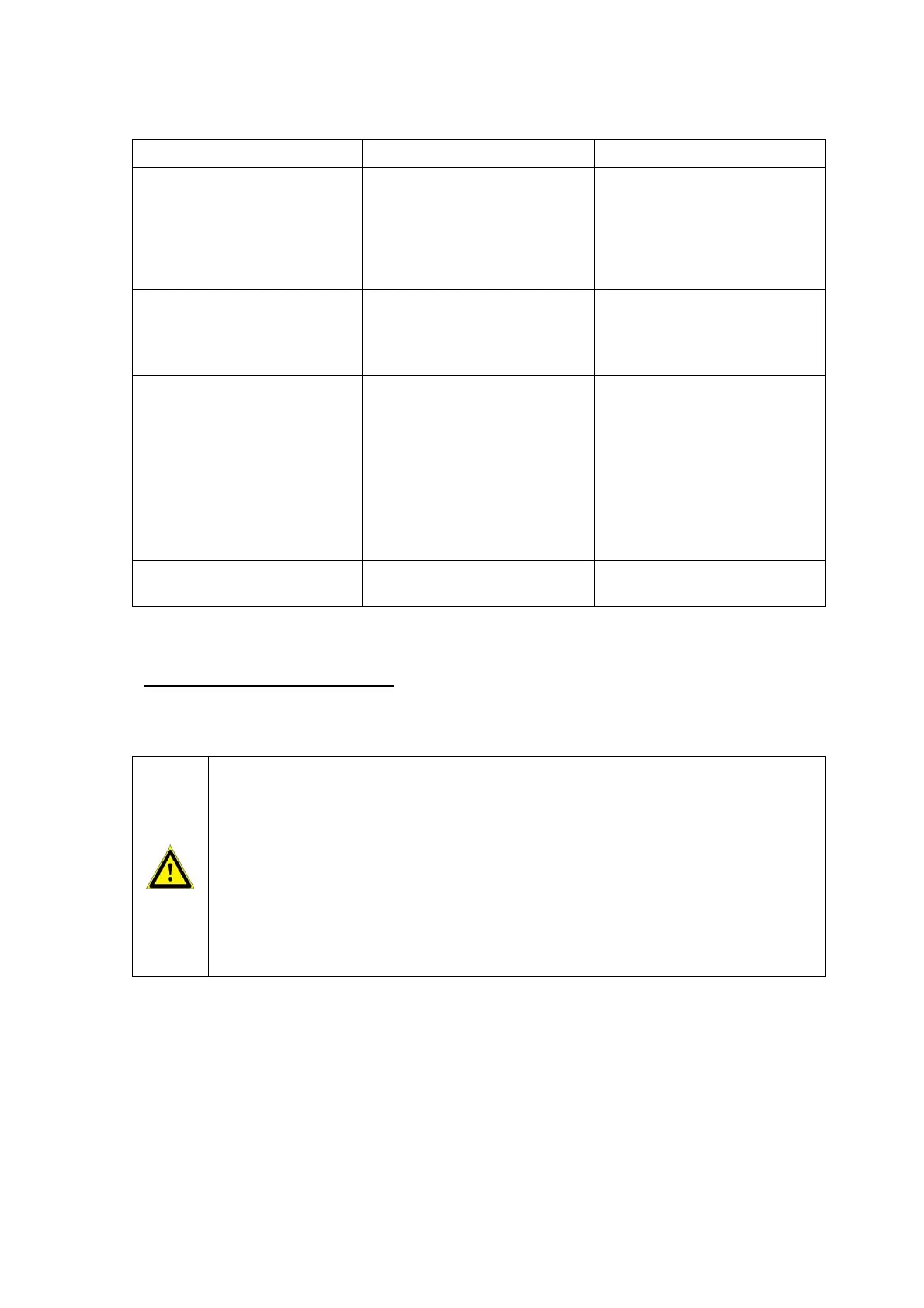

Malfunction Cause Remedy

Vibrations Coupling element or driven

machine poorly balanced

Inadequate alignment of the

drive train

Fixing screws loose

Rebalance

Realign machine set

Check and tighten screwed

connections

Running noises Foreign matter in motor

Damaged bearing

Repairs carried out by motor

manufacturer

Repairs carried out by motor

manufacturer

Temperature rise in the motor

Motor temperature monitoring

unit trips

Drive overload

Motor surface/air ducts soiled

Cramped installation

conditions

Brake does not release

sufficiently: grinding brake

Check motor load and

compare with nameplate

Clean motor surface/air ducts

Check motor has been

mounted in accordance with

Sect. 2.6 and 3

Repairs carried out by motor

manufacturer

Current consumption too high,

motor torque too low

Indexing angle incorrect Check indexing angle and

adjust if necessary

Table 3: Malfunctions

6 Inspection and maintenance

Working on the electric motor:

Work must not be carried out on the electric motor until the motor has come to a

standstill, is electrically isolated, and has cooled down. All connections, such as screw

connections, that were loosened when working on the motor must be tightened again

after the inspection and maintenance work.

When carrying out work on the motor, please observe the technical instructions and

notes in the respective sections in these Commissioning and Maintenance

Instructions.

When carrying out maintenance work, observe all safety instructions which also apply

to the commissioning of the motor (see Sect. 5.1).

Attention: if the optional holding brake is fitted, this brake must not perform a safety

function during work on the motor (e. g. retaining loads)!

6.1 Inspection

Depending on the severity of soiling on site, cleaning will have to be carried out regularly to

guarantee the continuous adequate dissipation of heat.

If an optional brake is fitted, wear limits are specified (e. g., maximum permissible operating air

gap, maximum number of emergency braking operations). The actual degree of wear on the brake

must be checked at regular intervals. If the permissible wear limits are reached, the brake must be

replaced (see Sect. 6.2).

If an optional shaft sealing ring is used, it must be checked at regular intervals to ensure it is

functioning correctly (leakage).

Loading...

Loading...