OV500G2-EE GAS OVEN

SPECIFICATIONS

1. WATER:

1/2" NPT, 30-75 PSI cold water required,

customer

to install in-line filter, shut off valve and

line strainer.

2. DRAIN:

2 3/4" (front) or 5 1/2" (rear) connection A.F.F.

SEE NOTES. Route to air-gap drain. Do not

slope drain upwards. Plug the drain connection

that is not in use. Kit provided to extend drain to

either side of oven.

Rear Drain: 3/4" NPTF

Front Drain: 3/8" NPTF

3. POWER:

Two supplies required.

120/60/1 20 AMP dedicated circuit required and

one of the following voltage options.

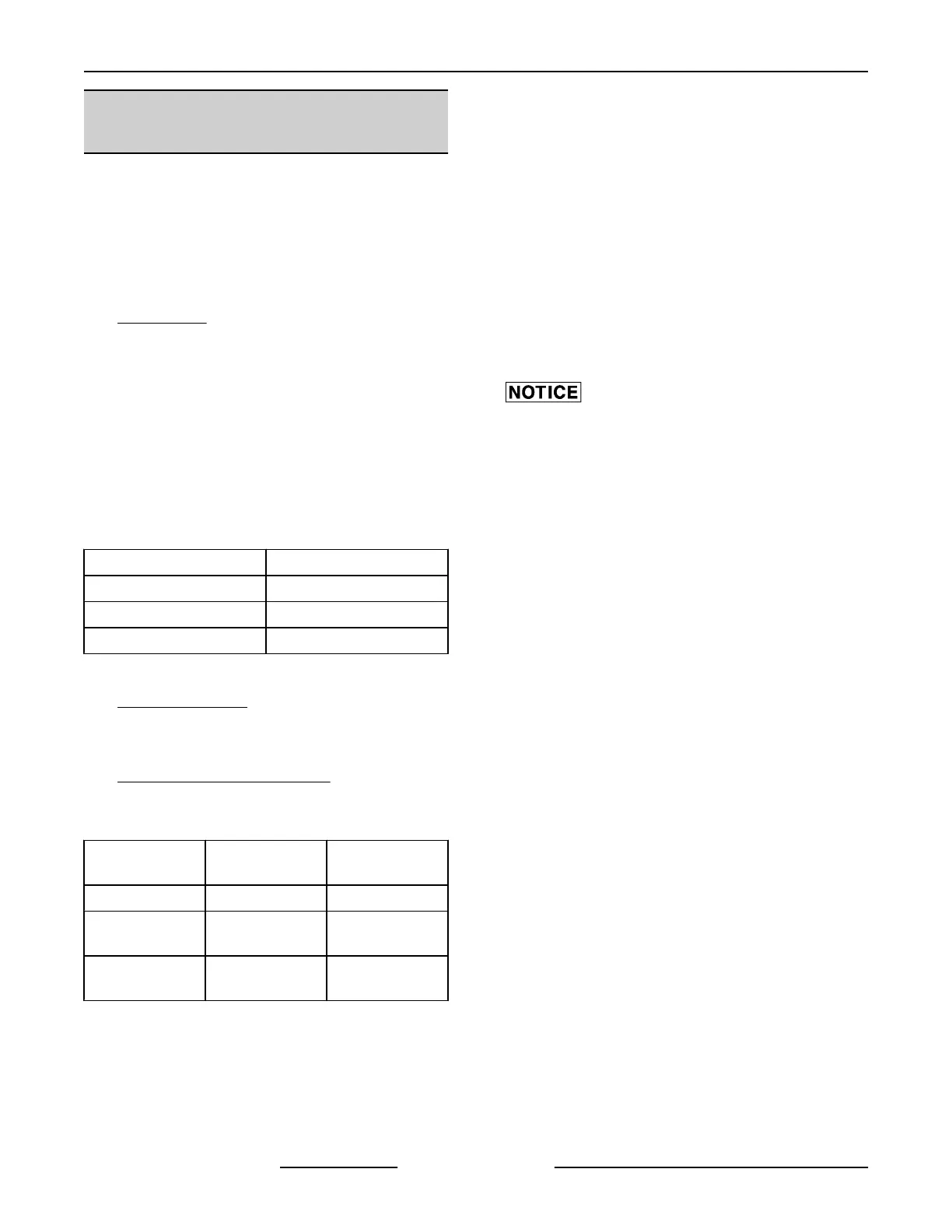

Voltage Full Load AMPS

208 - 240/60/1 8.8 - 7.6 AMPS

208-240/60/3 5.0 - 4.4 AMPS

440 - 480/60/3 2.4 - 2.2 AMPS

4. GAS:

Natural Gas (N.G.)

1

1/4" NPT, W.C.N.G. (N.G. rated 1025 BTU/CU.

FT. SP. GR. 1.00)

Liquified Propane Gas (L.P.G.)

1

1/4" NPT, W.C.L.P.G. (L.P.G. rated 2440 BTU/

CU.FT., SP. GR. 1.52)

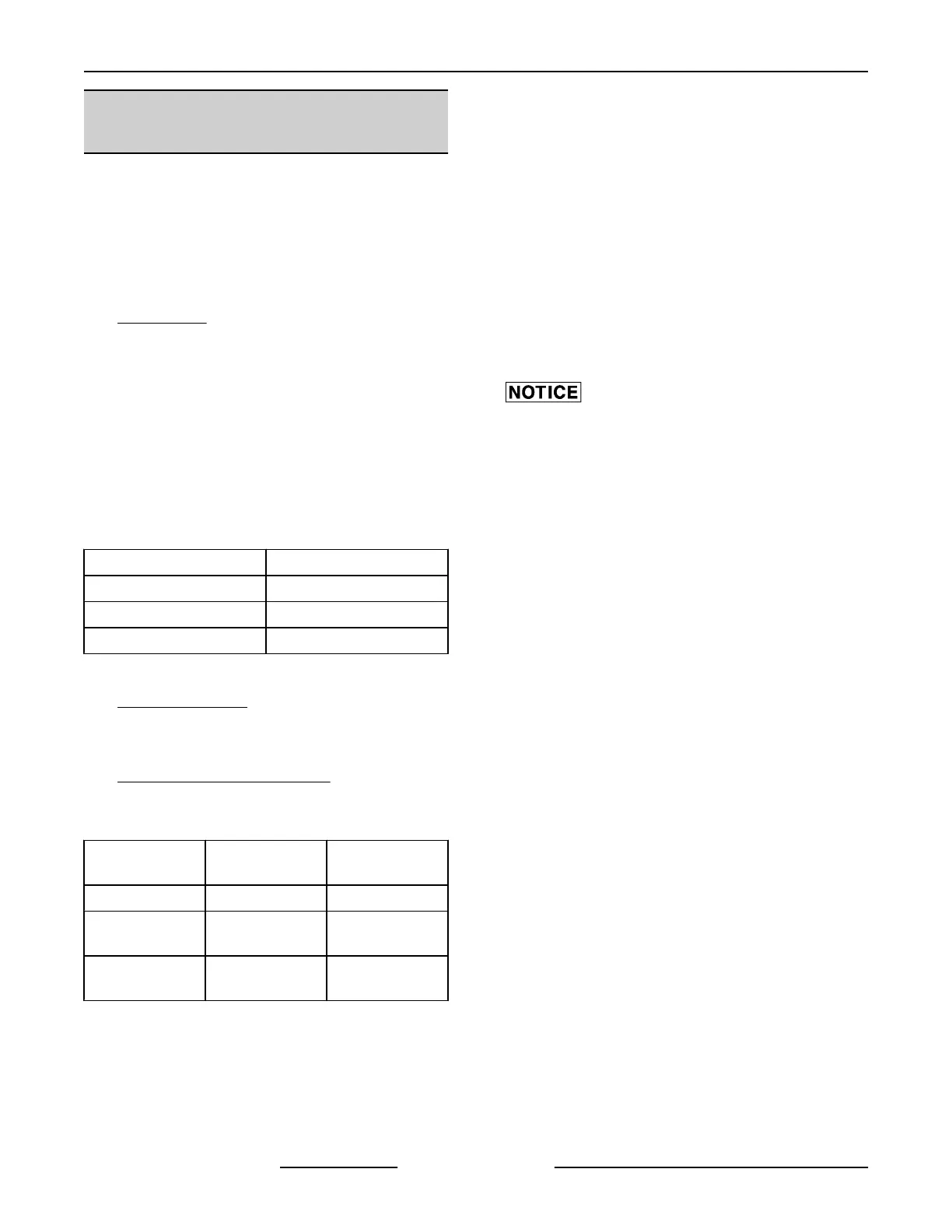

Natural Gas

Liquified

Propane Gas

BTU/HR 275,000 275,000

INLET

PRESSURE

5.0 -10.0" W.C.

10.0" - 14.0"

W.C.

MANIFOLD

PRESSURE

3.5" W.C. 8.75" W.C.

5. HOOD VENT:

10" DIA connection collar. Air proving switch

factory

installed & integrated with burner system

operation. Oven provided rely with max. 10 amp

1/2 H.P. @ 120V output for fan operation. If

larger, use oven relay to control additional

separately powered contactor / relay for hood

fan. Customer to supply duct and ventilator fan

per state and local codes. Chamber vents are

factory ducted to this integral hood. 900 CFM

required, 0.6" W.C. static pressure drop through

hood. Hood is UL710 Listed when grease filters

are installed. Type B gas vent can be used except

when bake products are grease laden.

NOTES:

1. A.F.F.: Above finished floor.

2. Customer responsible to finish and install all

utilities to and from oven.

3. All services must comply with all Federal, State

and Local codes.

To reduce the risk of fire, the appliance is

to be installed on non-combustible surface only, with

no combustible material within 18 inches above the

appliance. The appliance is to be mounted on floors

of non-combustible construction with non-combustible

flooring and surface finish and with no combustible

material against the underside, or on non-combustible

slabs or arches having no combustible material

against the underside. Such construction shall in all

cases extend not less than 12 inches beyond the

equipment on all sides.

4. The floor must be of non-combustible material,

and must be level with surrounding area with a

maximum slope of 1/8" per foot up to 3/4"

maximum in all directions. Floor anchors require

a minimum 1" thick solid floor substrate.

5. Oven is UL/C-UL classified and CSA (AGA/CGA)

approved for 0" clearance on the side and rear

walls. Unit requires 1" to 4" clearance for rear

drain connection.

6. Top of oven requires a minimum of 24" for service

accessibility.

7. Customer responsible to install flue piping. Flue

must be vented outside of building.

8. Manufacturer reserves the right to make changes

in sizes and specifications.

Export Ratings

1. WATER:

1/2” NPT, 2.1-5.2 Bar cold water required,

customer to install in-line filter, shut off valve and

line strainer. Flow rate of 8 l/min..

2. DRAIN:

INSTALLATION INSTRUCTIONS OV500-EE SERIES GAS RACK OVENS AND OV500 SERIES ELECTRIC RACK

OVENS - GENERAL

F45469 Rev. D (1019) Page 10 of 49

Loading...

Loading...