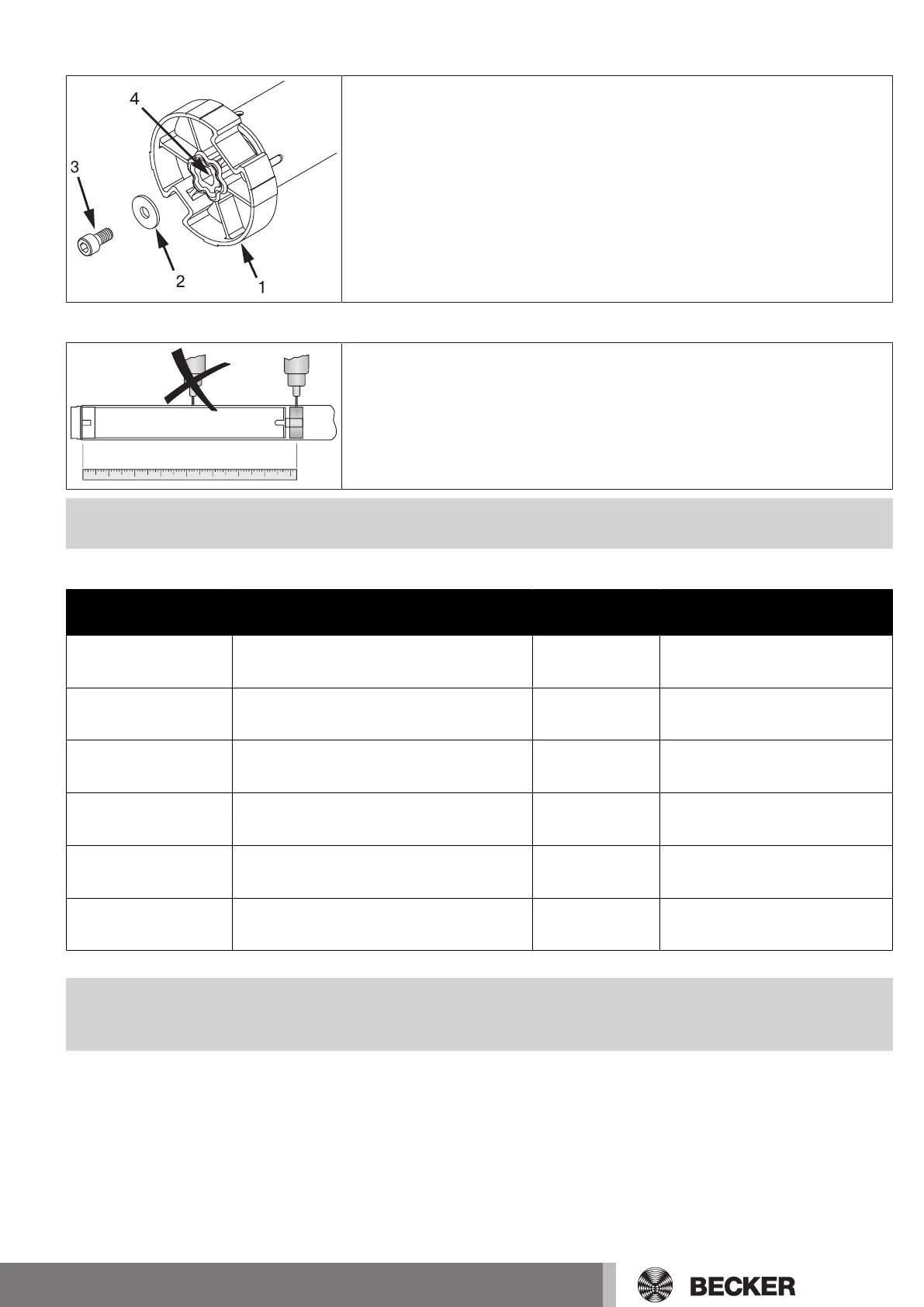

Assembling the drive adapter with screw connection

Put the drive adapter (1) onto the drive shaft of the tubular drive. For the assembly,

use an M6 x 12 screw (3) with appropriate washer (2) and suitable screw retainer.

Threaded hole (4)

Securing the drive against axial displacement

In order to secure the drive against axial displacement, we recommend screwing the

drive adapter to the tube.

Attention

When drilling into the barrel, never drill near the tubular drive!

Fixing the drive adapter to the barrel dia. 35 and dia. 45 and dia. 58

Size of drive

[mm]

Diameter of barrel

[mm]

Torque

max. [Nm]

Fastening screws

for drive adapter (4 pc.)

dia. 35

40 mm plastic drive adapter 13 Self-tapping screw

dia. 4.8 x 9.5mm

dia. 45

50-70mm plastic drive adapter 25 Self-tapping screw

dia. 4.8 x 9.5mm

dia. 45

50-85mm plastic drive adapter

for obstacle detection

40 Self-tapping screw

dia. 4.8 x 9.5mm

dia. 45

50 - 85 mm diecast drive adapter 50 Self-tapping screw

dia. 4.8 x 9.5mm

dia. 58

85-133mm aluminium drive adapter 120 Countersunk screw

M8 x 16mm

dia. 58

63-120mm diecast drive adapter 120 Self-tapping screw

dia. 6.3 x 13mm

We also recommend screwing the idler to the barrel.

Attention

Do not hammer the tubular drive into the tube or drop it into the barrel! The curtain can only

be secured using springs or anti-lifting devices.

9

Loading...

Loading...