Start up & adjust burner Service & maintain burner

10

Instruction Manual – Model NX Oil Burner

Beckett

Perform regular maintenance

Start up burner/set combustion

Do not attempt to start the burner when excess fuel or vapor

has accumulated in the appliance. Starting the burner under these conditions

could result in a puffback of hot combustion gases, high smoke levels, or

otherwise hazardous operation.

1. Open the shutoff valves in the oil supply line to the burner.

2. Set head/air adjustment screw setting to 3. This is an initial air setting for

the pump bleeding procedure only. Additional adjustments must be made

with instruments.

3. Set the thermostat substantially above room temperature.

4. Close the line voltage switch to start the burner. If the burner does not

start immediately you may have to reset the safety switch of the burner

primary control.

5.

Bleed air from fuel unit

as soon as burner motor starts rotating.

To bleed the fuel unit, attach a clear plastic hose over the vent fitting.

Loosen the fitting and catch the oil in an empty container. Tighten the

fitting when all air has been purged from the oil supply system.

• If the burner locks out on safety during bleeding, reset the safety

switch and complete the bleeding procedure. Note — Electronic

safety switches can be reset immediately; others may require a three-

to five-minute wait.

•

If burner stops after flame is established, additional bleeding is

probably required. Repeat the bleeding procedure until the pump is

primed and a flame is established when the vent fitting is closed.

•

For R7184 primary controls, see

Technician’s Quick Reference Guide

,

part number 61351 or 61465, for special pump priming sequence.

• Prepare for combustion tests by drilling a ¼" sampling hole in the flue

pipe between the appliance and the barometric draft regulator.

6.

Initial air adjustment

— Using a smoke tester, adjust the head/air setting

to obtain a clean flame. Now the additional combustion tests with

instruments can be made.

Set combustion with instruments

The combustion must be adjusted using test instruments.

Failure to do so could result in burner or appliance failure, causing potential

severe personal injury, death or substantial property damage.

1. Let burner run for approximately 5 to 10 minutes.

2. Set the over-fire or stack draft as specified by appliance manufacturer

(usually –0.01 to –0.02 inches w.c. over-fire for natural draft applications).

3. Follow these four steps to properly adjust the burner:

Step 1:

Adjust air until a trace smoke level is achieved.

Step 2:

At the trace of smoke level, measure the CO

2

(or O

2

). This is

the vital reference point for further adjustments.

• Example: 14.0% CO

2

(2.0% O

2

)

Step 3:

Increase the air to reduce CO

2

by 1 to 2 percentage points. (O

2

will be increased by approximately 1.5 to 2.5 percentage points.)

• Example: Reduce CO

2

from 14.0% to 12.0% (O

2

– 2.0% to 4.6%)

Step 4:

Recheck smoke level. It should be zero.

• This procedure provides a margin of reserve air to accommodate

variable conditions.

•

If the draft level has to be changed, recheck the smoke and CO

2

levels. Adjust the burner air if necessary.

4. Once combustion is set, tighten all fasteners on head/air adjusting

mechanism.

5. Reinstall the cover and repeat Steps 2 and 4 above. If CO

2

increases (O

2

decreases), remove the cover and adjust the air setting so the CO

2

(O

2

)

with cover on meets requirements of Step 3.

6. Start and stop the burner several times to ensure satisfactory operation.

Test the primary control and all other appliance safety controls to verify

that they function according to the manufacturer’s specifications.

This equipment must be serviced only by a qualified service

agency. The appropriate test instruments must be used. Failure to do so could

result in burner or appliance failure, causing potential severe personal injury,

death or substantial property damage.

Replace the oil supply line filter. The line filter cartridge must be replaced

to avoid contamination of the fuel unit and nozzle.

Inspect the oil supply system. All fittings should be leak-tight. The supply

lines should be free of water, sludge and other restrictions.

Remove and clean the pump strainer if applicable.

Replace the nozzle with an equivalent nozzle.

Clean and inspect the electrodes for damage, replacing any that are

cracked or chipped.

Check electrode tip settings. Replace electrodes if tips are rounded.

Inspect the igniter spring contacts.

Clean the cad cell grid surface, if necessary.

Make sure Low Firing Rate Baffle is in place if required for the burner

application. Omitting the baffle can result in unacceptable burner

combustion.

Inspect all gaskets. Replace any that are damaged or would fail to seal

adequately.

Clean the blower wheel, air inlet, air guide, retention head, throttle plate

and throttle ring of any lint or foreign material.

If motor is not permanently lubricated, oil motor with a few drops of SAE

20 nondetergent oil at each oil hole. DO NOT over oil motor. Excessive

oiling can cause motor failure.

Check motor current. The amp draw should not exceed the nameplate

rating by more than 10%.

Check all wiring for secure connections or insulation breaks.

Check the pump pressure and cutoff function.

Check primary control safety lockout timing.

Check ignition system for proper operation.

Inspect the vent system and chimney for soot accumulation or other

restriction.

Clean the appliance thoroughly according to the manufacturer's

recommendations.

Check the burner performance. Refer to the section “Set combustion

with instruments

”.

It is good practice to make a record of the service performed and the

combustion test results.

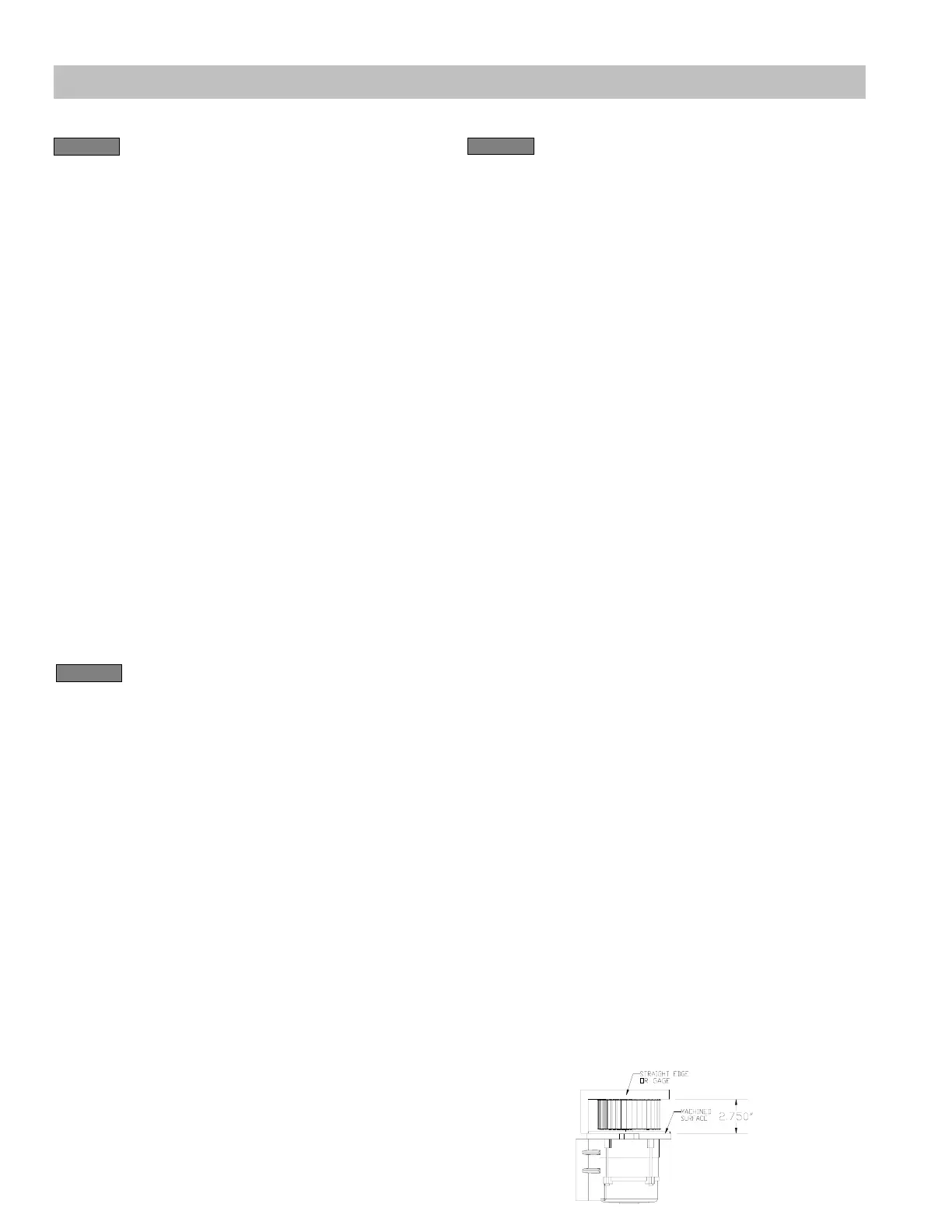

To replace the blower wheel:

1. Turn off all power to the burner before servicing.

2. Disconnect the burner motor wires.

3. Remove the bolts securing the motor to the burner, remove motor.

4. Remove the existing blower wheel from the motor.

5. Slide the new blower wheel onto the shaft.

• Place a straight edge across blower wheel as shown.

•

Slide blower wheel up shaft , 2.750” from machined motor mounting

surface to straight edge.

• Rotate the blower wheel until the setscrew is centered on the flat of the

motor shaft. Tighten the setscrew to secure the wheel.

6. DO NOT use a motor that has endshield openings outside the blower

wheel circumference.

7. Install the motor on the burner housing. Tighten screws. Reconnect wires.

8. Restore power, start the burner and perform combustion tests. Refer to

the section “

Set combustion with instruments

”.

SK9670

WARNING

WARNING

WARNING

Loading...

Loading...