Do you have a question about the Beckman Coulter COULTER EPICS XL and is the answer not in the manual?

| Brand | Beckman Coulter |

|---|---|

| Model | COULTER EPICS XL |

| Category | Laboratory Equipment |

| Language | English |

Alerts to potential hazards and provides operational guidelines, including warnings, cautions, and important notes.

Outlines the scope, audience, organization, and conventions used within the service manual.

Covers critical safety precautions for electronic, biological, and laser hazards associated with the instrument.

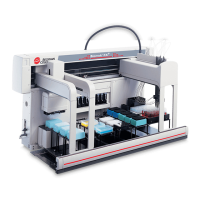

Provides a general understanding of the instrument's function, major components, and networking capabilities.

Details the instrument's core components, including optics, laser, flow cell, and signal processing systems.

Describes the function and components of the power supply module, which provides essential power to the instrument.

Explains the components and standard configuration of the computer workstation used with the instrument.

Covers basic understanding of networks, Beckman Coulter's implementation, and common topologies.

Lists preinstallation requirements and outlines the necessary steps for installing the instrument.

Details the conditions to verify before installing the instrument, including space, power, and environment.

Outlines checks to be performed before beginning the instrument installation to ensure readiness.

Provides step-by-step procedures for unpacking and installing the instrument's main components.

Guides through the setup and connection of the computer workstation, monitors, keyboard, and mouse.

Details the procedures for connecting all necessary cables and tubing between the instrument components.

Covers the installation process for the SYSTEM II software, essential for instrument operation.

Outlines the procedures for verifying the instrument's proper operation after installation.

Provides procedures for installing various upgrades and options available for the instrument.

Details the step-by-step process for installing the MCL option onto the instrument.

Guides through the process of upgrading the instrument from three colors to four colors.

Provides instructions for installing the FlowCentre II Multimedia Workstation.

Guides through the installation and connection of the bar-code printer to the CPU.

Provides instructions for installing and connecting the hand-held bar-code scanner.

Guides through the installation of the Serial/Parallel Adapter Interface Card.

Provides instructions for setting up a network for computer communication.

Details the installation of LANtastic Client/Server software, version 8.0.

Provides procedures to reinstall LANtastic Client/Server software V7.0.

Guides through reinstalling LANtastic Client/Server software V6.0.

Provides instructions for installing Sybase Client/Server SQL software.

Details the installation of EXPO32 software for acquisition and data management.

General guidelines, safety precautions, instrument access, laser, and electronic precautions for servicing.

Instructions for installing and operating the Prefinal Service software for troubleshooting.

Procedures for removing and reinstalling various covers and panels of the instrument.

Procedures for replacing the Argon laser head or power supply.

Procedures for replacing or aligning the flow cell and beamshaper assembly.

Performs optical alignment procedures, often after component replacement or PMI.

Provides instructions for field calibration of sheath pressure and sample station vacuum regulators.

Verifies sample carryover in the sample tubing and flow cell area.

Procedure for replacing PEEK tubing when conditions like excessive carryover or high CVs are present.

Instructions for field calibration of sheath pressure and sample station vacuum regulators.

Procedure for cleaning the segmenting valve to resolve performance issues.

Procedures for properly aligning and adjusting the MCL option.

Procedure to replace the vortexer foot if the bearing is binding.

Procedure to adjust ADC offset or verify offset for Trans Data Acquisition and Amp/Signal Conditioner cards.

Procedure for replacing or calibrating Amp/Signal Conditioner cards.

Procedure to prepare the instrument for shipment.

Procedure to ensure proper shutdown of the instrument before leaving the site.

Procedure to test the electrical wiring faults of the instrument's receptacle.

Procedure to replace or verify operation of power supply components.

Procedure to verify and adjust voltages at various power supplies.

Instructions for re-imaging FlowCentre desktop or tower computers.

Instructions for installing a driver for CD-ROM drives on any computer using Windows 95 or higher.

Instructions on how to reprogram the bar-code scanner EEPROM for custom configurations.

Procedure performed at the end of a service call to ensure instrument functionality before departure.

Procedure to perform a Preventative Maintenance Inspection on the instrument.

Lists and explains level sense indicators and common error messages encountered during operation.

Details various diagnostic tests available within the Prefinal Service software for troubleshooting.

Provides a master list of all components, categorized by common names and categories.

Offers illustrations of instrument components, organized by functional groups for easy identification.