General Information

39

Appendix 3 continued

Calibrating the FLR Horizontal Alignment

After the physical horizontal alignment has been conducted on the chassis, there is a calibration procedure that should be implemented

prior to delivery to the customer. This can also be performed as a service function at any point in time, if required. The calibration procedure

requires the use of diagnostic software on a mobile computer that can be operated in the cab while the vehicle is in motion.

This procedure requires two people. The driver must not attempt to perform the calibration procedure while driving the vehicle.

In order to perform this procedure, the VORAD equipped vehicle must be traveling on a straight road at a speed above 30 mph behind a

target vehicle traveling in the same lane. The Bendix

™

VORAD

®

-equipped vehicle should be placed into SmartCruise

®

mode behind this

target vehicle. If the VORAD

®

system is not Bendix

™

SmartCruise

®

adaptive cruise control-equipped, position the vehicle manually 200 to

300 feet behind the target vehicle. At highway speeds, this can be approximated by the VORAD

®

DIU displaying a following distance of "2

seconds" or "3 seconds."

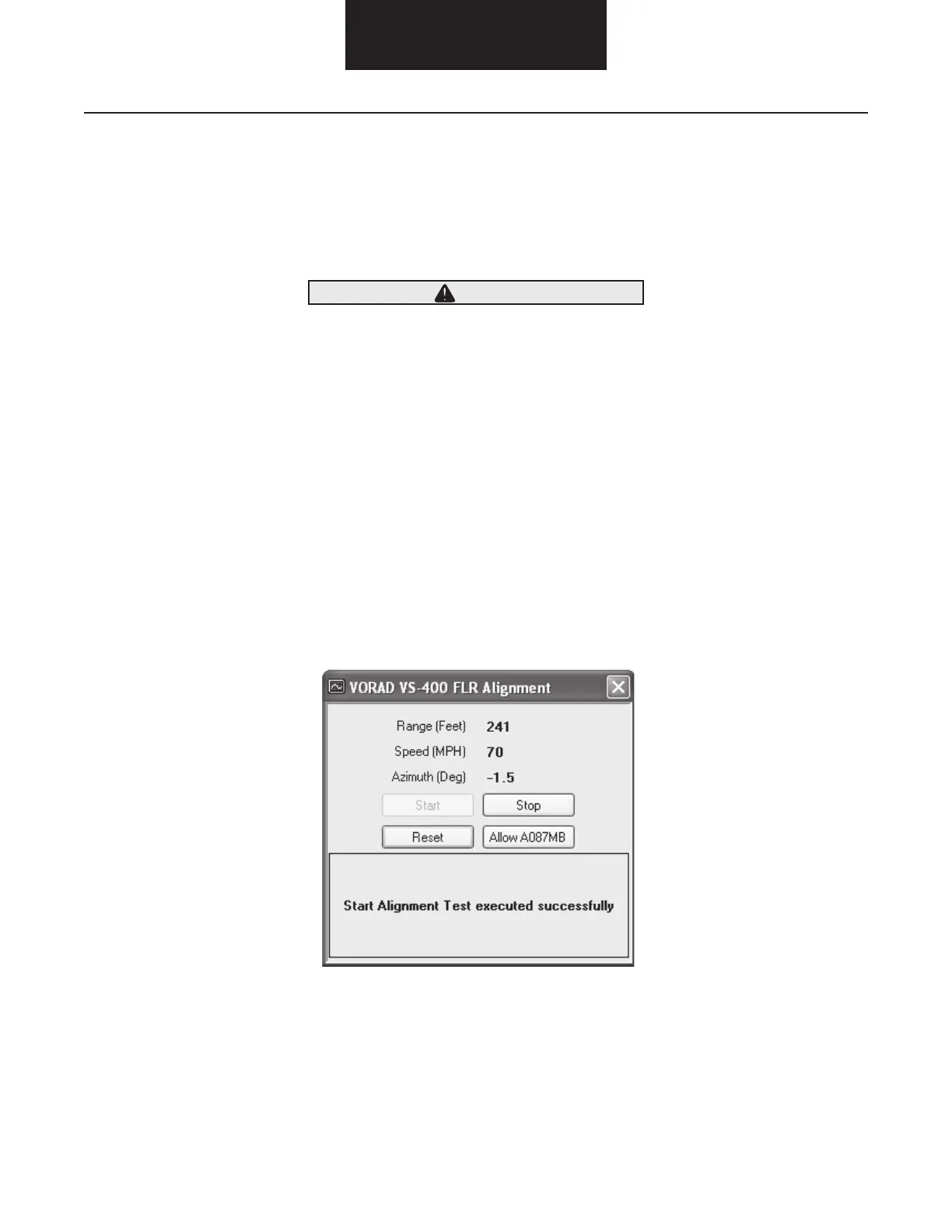

Double click on the option for "VORAD

®

VS-400 Alignment Tests."

Follow the steps shown on the diagnostic software.

Continue to run the truck for a period of time (2-5 min), monitoring the azimuth value. As long as the vehicle the VORAD

®

system is tracking

isinthesamelane,theazimuthpositionshouldbe0°,butuctuationsindrivingtechniquesmaycausethevehicletodrift+/-0.3°.Ifthis

value cannot be consistently kept, click the "Reset" button again and monitor the azimuth position. If the position is consistently more than

0.5°orlessthan-0.5°,theFLRhorizontalalignmentmustbeadjustedbasedontheaverageazimuthposition.

Note: For best results it is recommended that the driver perform the alignment test for 2-5 minutes to verify correct tracking of vehicles in

the same lane.

CAUTION

Loading...

Loading...