1515

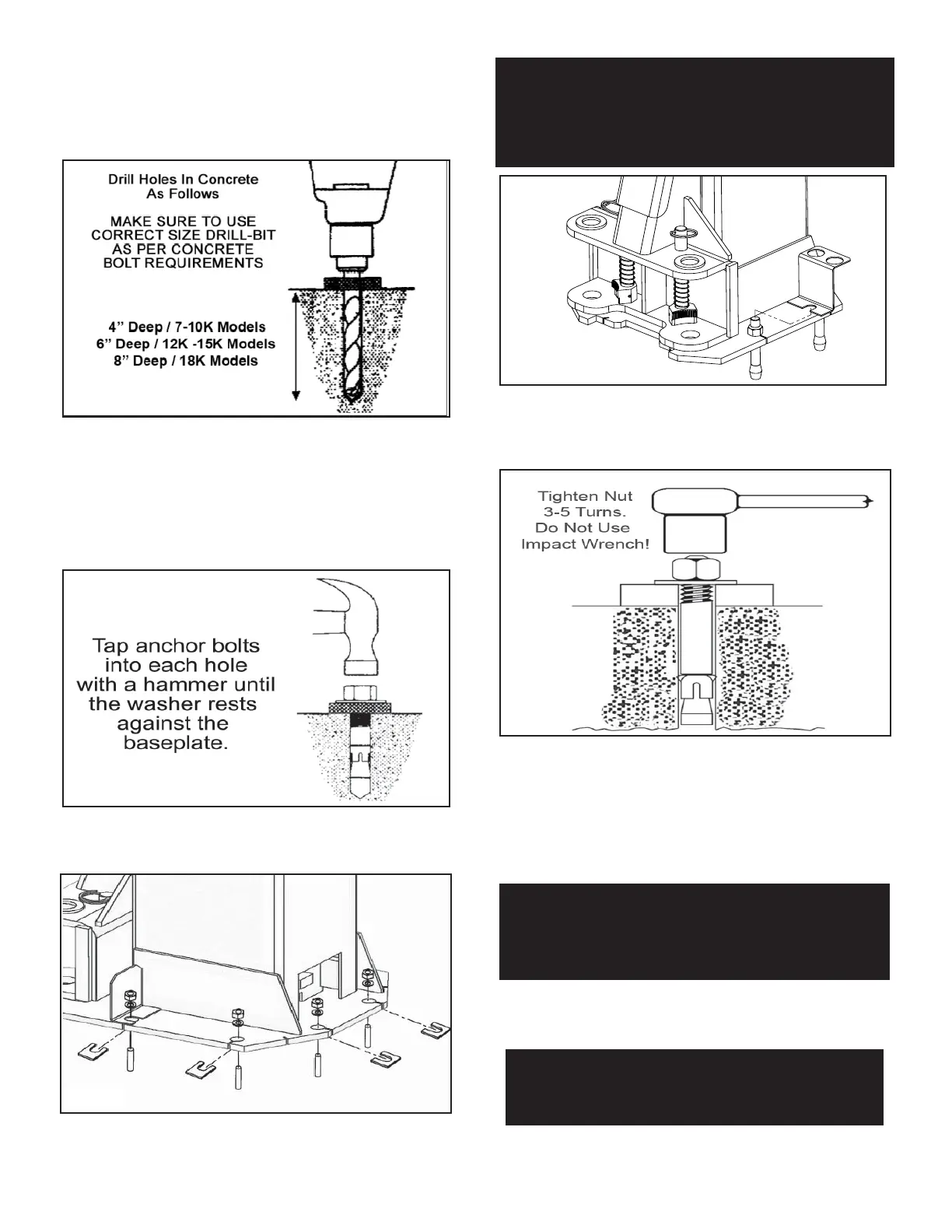

2. Using the baseplate on the POWER SIDE post as a

guide, drill each anchor hole in the concrete (approximately

4” deep for 10K models and 6” deep for 12K and 15K; 8” for

18K models) using a rotary hammer drill and 3/4” concrete

drill-bit. To ensure full holding power, do not ream the hole

or allow the drill to wobble. (See Fig. 5.1)

3. After drilling, remove dust thoroughly from each hole

making certain that the posts remain aligned with the

chalk line.

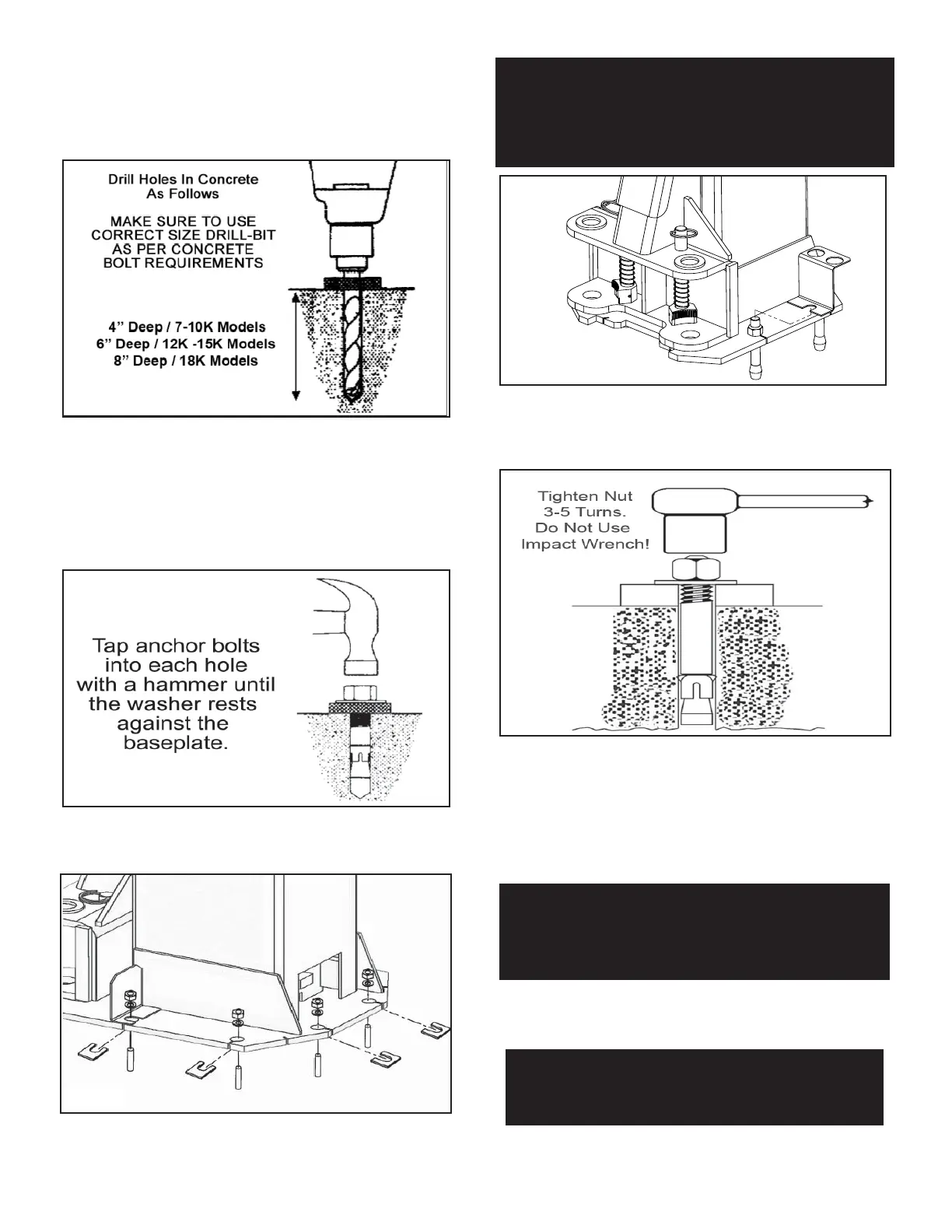

4. Assemble the washers and nuts on the anchors then

tap into each hole with a hammer until the washer rests

against the base plate. If shimming is required be sure

that enough threads are left exposed. (See Fig. 5.2)

5. If shimming is required, insert the shims as necessary

under the base plate so that when the anchor bolts are

tightened, the posts will be plumb. (See Fig. 5.3)

6. If installing the optional foot guards, place foot guards

on left and right side as shown. (See Fig 5.4)

7. With the foot guards, shims and anchor bolts in place,

tighten by securing the nut to the base then turning 3-5 full

turns clockwise (90 ft-lbs.). DO NOT use an impact wrench

for this procedure. (See Fig. 5.5)

STEP 6

(Installing the OFF SIDE post)

1. Position the OFF SIDE post at the designated chalk

locations and secure post to oor following the same proce-

dures as outlined in STEP 5; Paragraphs 1-6.

STEP 7

(Mounting the Overhead Assembly)

1. Remove all of the equalizer cable sheaves in prepara-

tion for the installation of the Overhead Assembly.

Fig 5.1

Fig 5.2

Fig 5.3

Fig 5.4

Fig 5.5

NOTE:

TO EASE THE INSTALLATION OF THE OVERHEAD

ASSEMBLY, IT HELPS TO KEEP THE ANCHOR BOLTS

LOOSE ON ONE OF THE POSTS UNTIL THE OVER-

HEAD ASSEMBLY IS MOUNTED.

NOTE:

IN ORDER TO ROUTE THE EQUALIZER CABLES

THE SHEAVES MUST BE REMOVED.

NOTE:

TO EASE INSTALLATION OF THE OVERHEAD

ASSEMBLY, IT HELPS TO KEEP THE ANCHOR

BOLTS LOOSE ON ONE OF THE POSTS UNTIL THE

OVERHEAD ASSEMBLY IS MOUNTED.

Loading...

Loading...