GENERAL RULES

The installation of an oil burner should

be carried out in accordance with local

regulations. The installer of the burner

must therefore be aware of all

regulations relating to oil and combu-

stion.

Only oil suitable for the burner should

be used and then in combination with

a suitable oil filter before the oil pump

of the burner.

If the burner is replacing an existing

burner make sure that the oil filter is

replaced or cleaned. The installation

must only be undertaken by experien-

ced personnel. Care should be taken

by the installer to ensure that no

electrical cables or fuel/gas pipes are

trapped or damaged during installation

or service/maintenance.

INSTALLATION INSTRUCTIONS

General installation instructions ac-

company the burner and should be left

in a prominent place adjacent to the

burner.

ADJUSTMENT OF BURNER

The burner is from the factory pre-set

to an average value that must then be

adjusted to the boiler in question.

All burner adjustments must be made

in accordance with boiler manufacturers

instructions.These must include the

checking of flue gas temperatures,

average water temperature and CO

2

or

O

2

concentration.

To adjust the combustion device, start

by increasing the air volume somewhat.

When the burner starts it is burning

with excess air and smoke number 0.

Reduce the air volume until soot occurs

and increase again to reach a

combustion free of soot.

By this procedure an optimum adjust-

ment is obtained. If larger nozzles are

used the preadjustment of the air

volume must be increased.

CONDENSATION IN CHIMNEY

A modern burner works with less ex-

cess air and often also with smaller

nozzles than older models. This

increases the efficiency but also the

risk of condensation in the chimney.

The risk increases if the area of the

chimney flue is too large. The tempera-

ture of the flue gases should exceed

60°C measured 0,5 metres from the

chimney top.

Measures to raise the temperature:

Insulate the chimney in cold attics

AIR ADJUSTMENT

On all burners the air adjustment can

be made with or without the cover

fitted. Final fine adjustment must be

made with the cover on.

MAINTENANCE

The boiler/burner should be exami-

ned regularly for any signs of mal-

function or oil leakage.

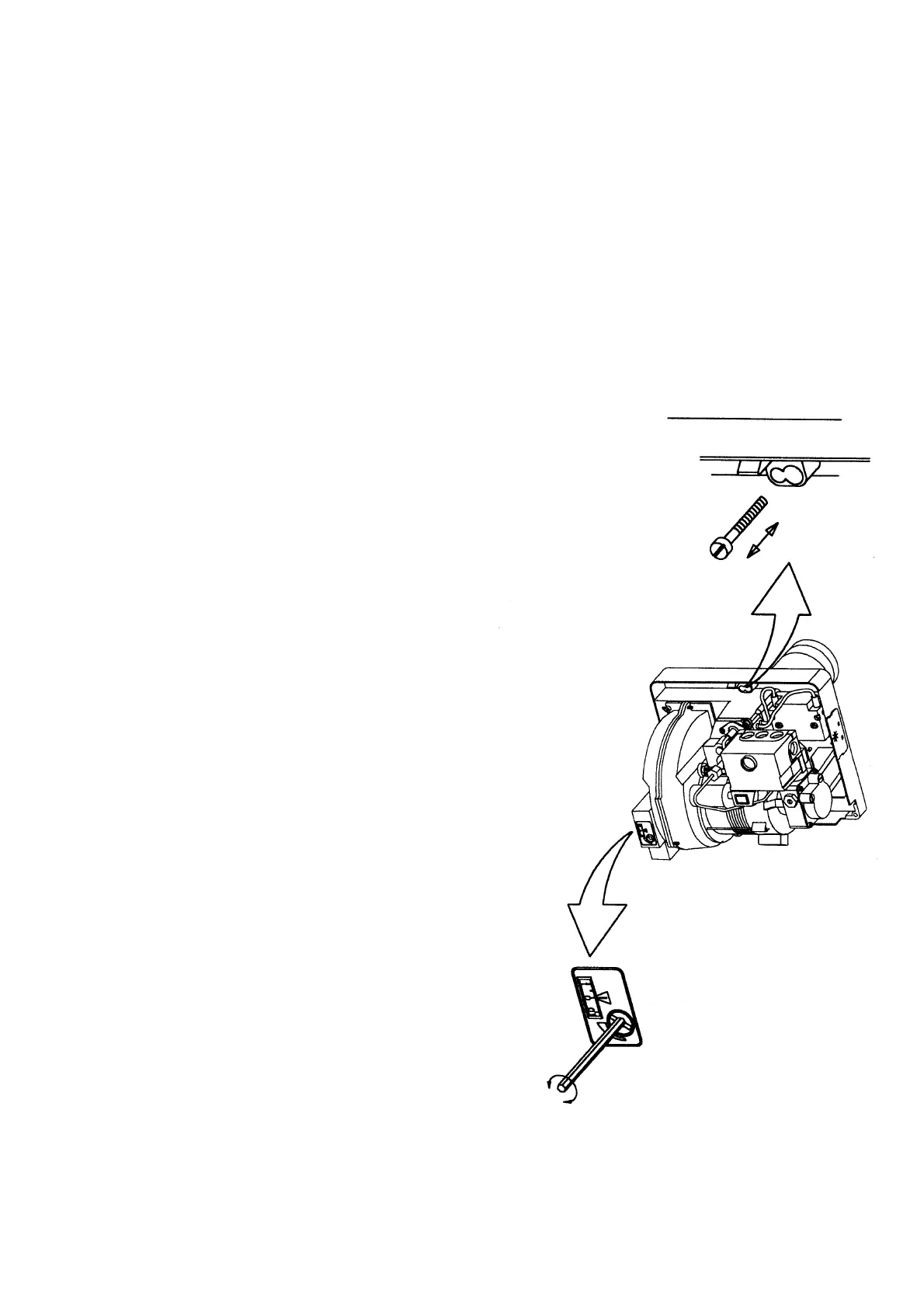

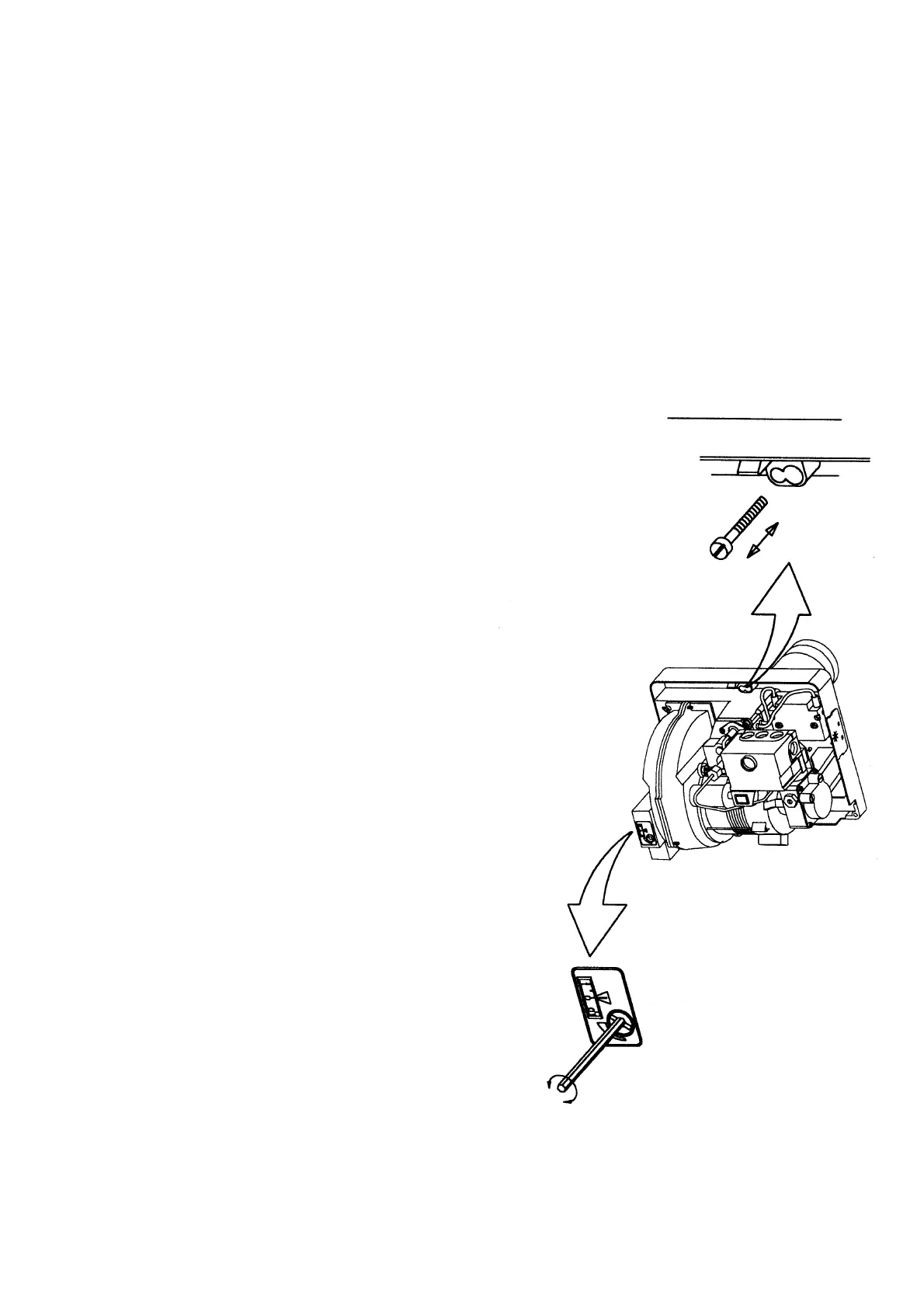

FASTENING OF THE BURNER

TO THE BOILER (FLANGE)

GENERAL INSTRUCTIONS

Install a tube in the chimney

Install a draught regulator (dilutes the

flue gases during operation and dries

them up during standstill)

Increase the oil quantity

Raise the flue gas temperature by

removing turbulators, if any, in the

boiler.

INSTRUCTIONS FOR USE

The end user of the burner should be

instructed about the operation and

safety features of the burner.

He should also be made aware of the

importance of the area around the

boiler/burner being kept free of combu-

stible material.

PUMP ADJUSTMENT

See separate description.

ADJUSTMENT OF BURNER

To obtain a correct adjustment a flue

gas analysis and a temperature

measurement must be carried out.

Otherwise there is a risk that a bad

adjustment may cause a formation of

soot, bad efficiency or condensate in

the chimney.

AIR ADJUSTMENT

171 305 17 06-01

Loading...

Loading...