13

caldaie

2.4 PRESSURE CALIBRATION ON THE

BURNER

2.4.1 Preliminary operations

The following are necessary for calibration and checks: a

pressure gauge (differential manometre), a medium flat

screwdriver, as well as 10-mm socket wrenches.

Act as follows:

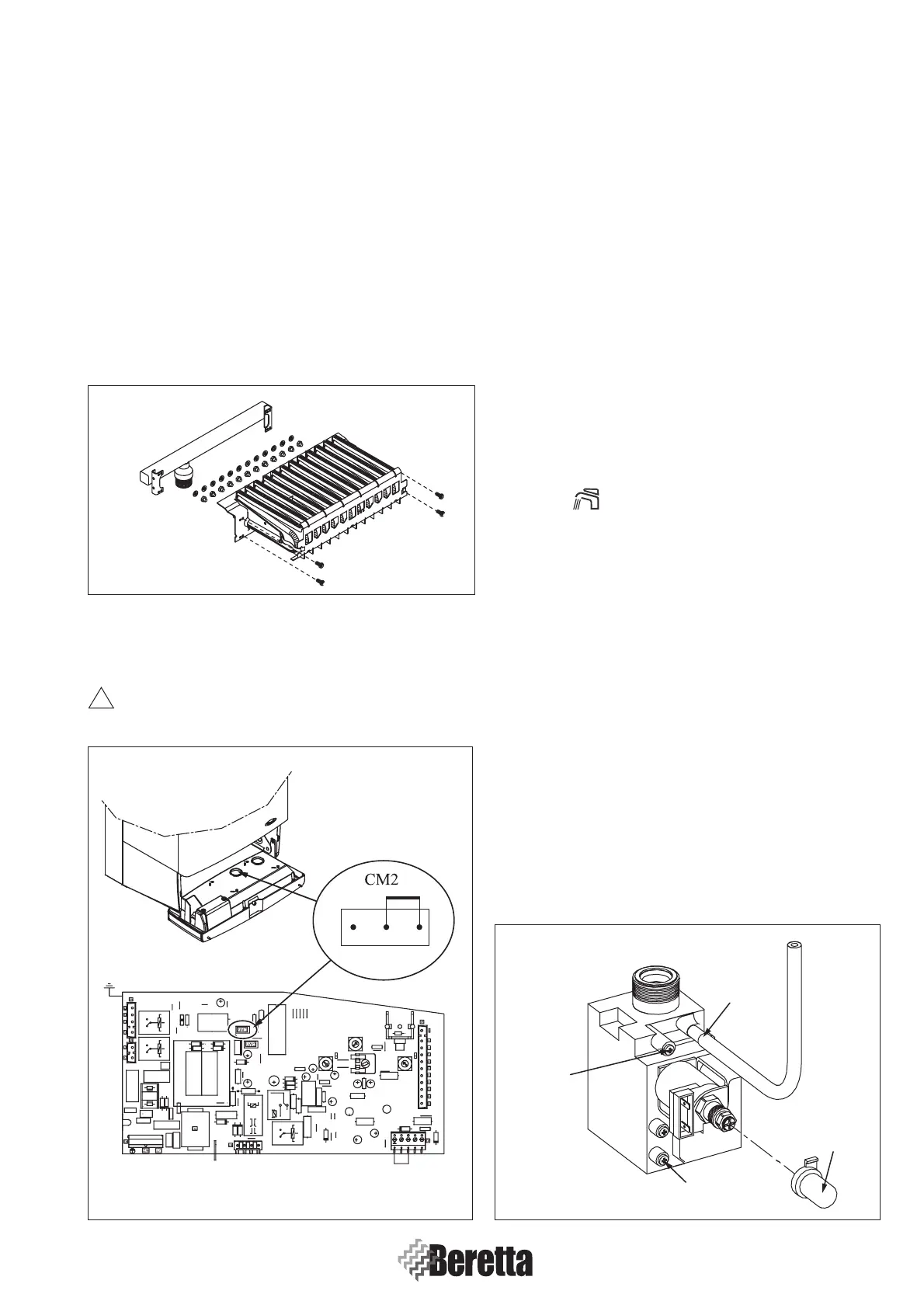

- connect pressure gauge to pressure outlet (1 - Fig. 2.13)

upstream of gas valve;

- check static pressure, with boiler off, does not exceed the

limit value of 50 mbar;

- enable « » DHW operation by dashboard controls;

- select maximum DHW temperature value;

- fully open DHW cock and check, by pressure gauge

connected, that gas dynamic pressure is not below the

following values:

- 15 mbar for methane

- 37 mbar for LPG

- disconnect pressure gauge and close outlet (1 - Fig. 2.13).

2.4.2 Pressure calibration on the burner

See the following operations:

- disconnect compensating outlet (4 - Fig. 2.13) of gas val-

ve (C.S.I. only);

- connect a pressure gauge end to pressure outlet (2 - Fig.

2.13) downstream of gas valve and the other end to

compensating outlet on air chamber (C.S.I. only);

- select maximum DHW and CH temperature values by

controls;

- remove protection cap from idling adjusting screw (3 -

Fig. 2.13).

2.3 GAS TRANSFORMATION

PROCEDURES

Shifting from a gas to another, belonging to another group, is

easy also when the boiler is already installed. For the relevant

pressure values, refer to “GAS PRESSURE TABLE”

APPENDIX - D page 80.

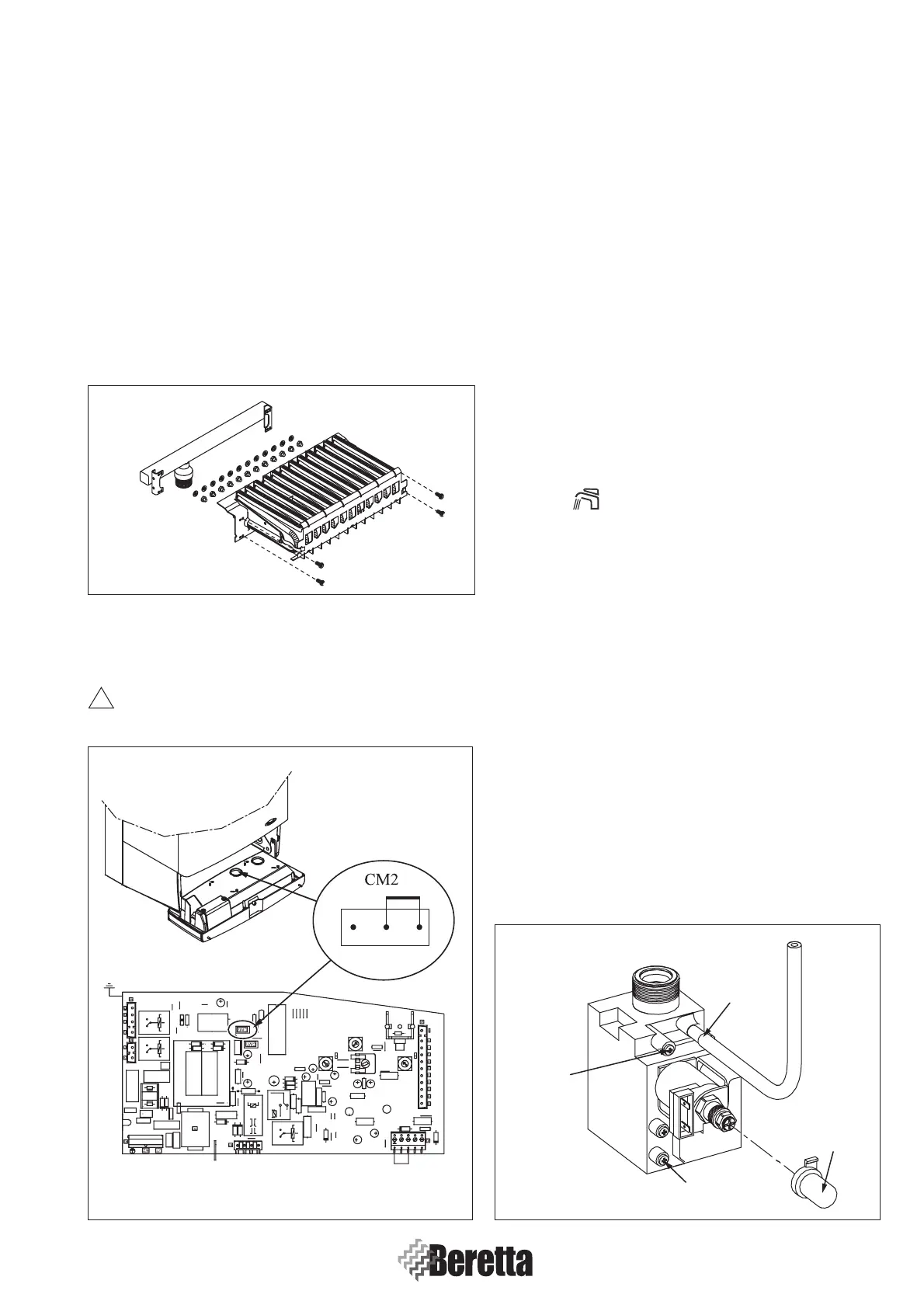

Replace burner nozzles as follows (see table 4.4.14 pages 37

and 38):

- stop boiler voltage and close gas central cock;

- remove the cover;

- remove combustion chamber front cover;

- remove burner unit by untightening screws (A) fixing it to

gas manifold (Fig. 2.11).

Now, replace nozzle with manifold installed on the boiler;

install nozzles using new gaskets available in the

transformation kit.

Carefully check nozzle cleaning: also a partial

obstruction would seriously affect combustion.

Fig. 2.11

Fig. 2.13

Fig. 2.12

!!

TRASFORMATION FROM LPG TO MTN

- Remove jumper installed in control board, in position CM2

(Fig. 2.12).

TRASFORMATION FROM MTN TO LPG

- Place jumper available in the kit in position CM2 in control

board, as shown in figure 2.12.

4

2

1

3

Loading...

Loading...