24 25

MAINTENANCEPRACTICAL SEWING

Please refer to page 11 DIFFERENTIAL FEED.

Differential feed is designed to minimize puckering and wavering. It is also very

effective for gathering.

1. Puckering

Puckering tends to occur on woven or sheer fabrics. To obtain pucker-free

seams, set the differential feed control dial at less than 1.

2. Wavering

Wavering tends to occur on knitted or stretchable fabrics. To obtain waver-

free seams, set the differential feed control dial at more than 1.

3. Gathering

Differential feed makes gathering easier on lightweight fabric. Use it on

waistlines, sleeve heads, sleeve bottoms and ruffles, etc.

Set the differential feed control dial between 1.5 and 2 to obtain the best

gathering effect for your use.

NOTE

The exact adjustment depends on the thickness and elasticity of fabric. Even

the stitch length can influence the setting. The longer the stitches, the more the

fabric is contracted.

Always do a test run with a piece of actual fabrics you use and find the best

settings.

DIFFERENTIAL FEED APPLICATIONS REPLACING MOVING CUTTER

DISENGAGING MOVING CUTTER

REPLACING THE SEWING-LIGHT BULB

MAINTENANCE

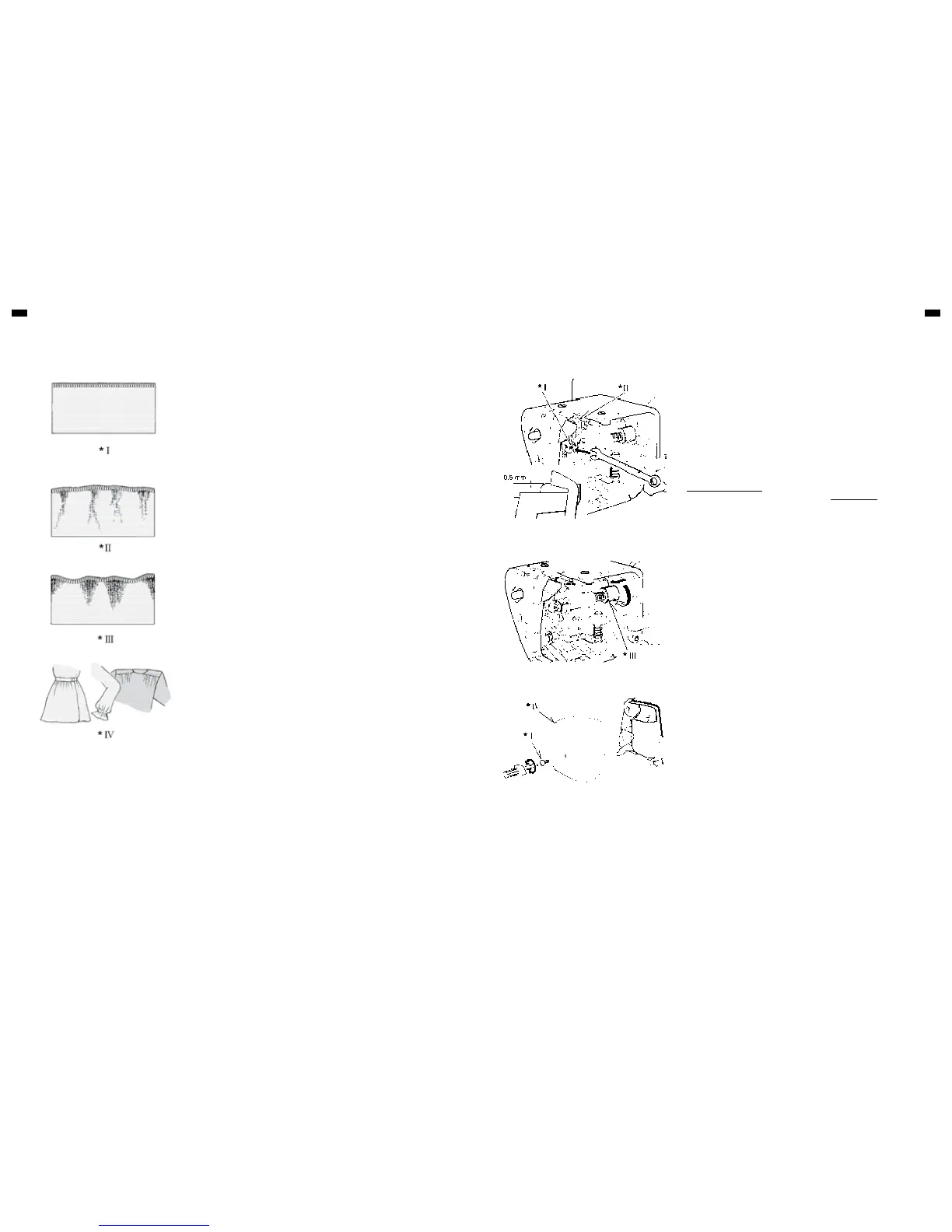

Replace a moving cutter if it becomes blunt as follows. A spare cutter will be

found in your accessories.

NOTE:

You should not need to replace fixed cutter, which is made of a special hard

alloy material.

FIRST REMOVE THE POWER PLUG FROM THE SUPPLY SOCKET-

OUTLET.

1. Loosen screw and take out moving cutter.

2. Close the working table. Lower cutter driving arm to its lowest position by

turning the hand wheel towards you by hand. In this position, set

replacement cutter in position and secure it with screw, ENSURING THAT

THE EDGE OF THE MOVING CUTTER IS APPROXIMATELY 0.5 MM

BELOW THE SURFACE OF THE FIXED CUTTER.

If you want to sew without cutting, open the working table and disengage the

moving cutter by pushing the cutter release knob to the left and turning it

towards you as illustrated.

Ensure that fabric edge is not wider than overedge width selected or upper

looper and needle can be damaged.

Switch machine off before removing the face cover.

Remove screws and face cover as illustrated. Push thermal screen aside to

access the bulb. Unscrew and remove defective bulb. After replacing the bulb,

push thermal screen back into its basic position. Refit face cover and retighten

screws.

Illustration

I. Screw

II. Moving cutter

III. Cutter release knob

IV. Face cover

Illustration

I. Pucker or waver-free seams

II. Puckering

III. Wavering

IV. Gathering

Loading...

Loading...