10 11

OPERATING INSTRUCTIONOPERATING INSTRUCTION

Overedge cutting width can be adjusted from 4 to 7

mm by simply turning overedge cutting width dial

according to the kind of fabric.

It is set at standard width of 6 mm when delivered

from the factory.

Turn it towards “5” if fabric edge curls while sewing.

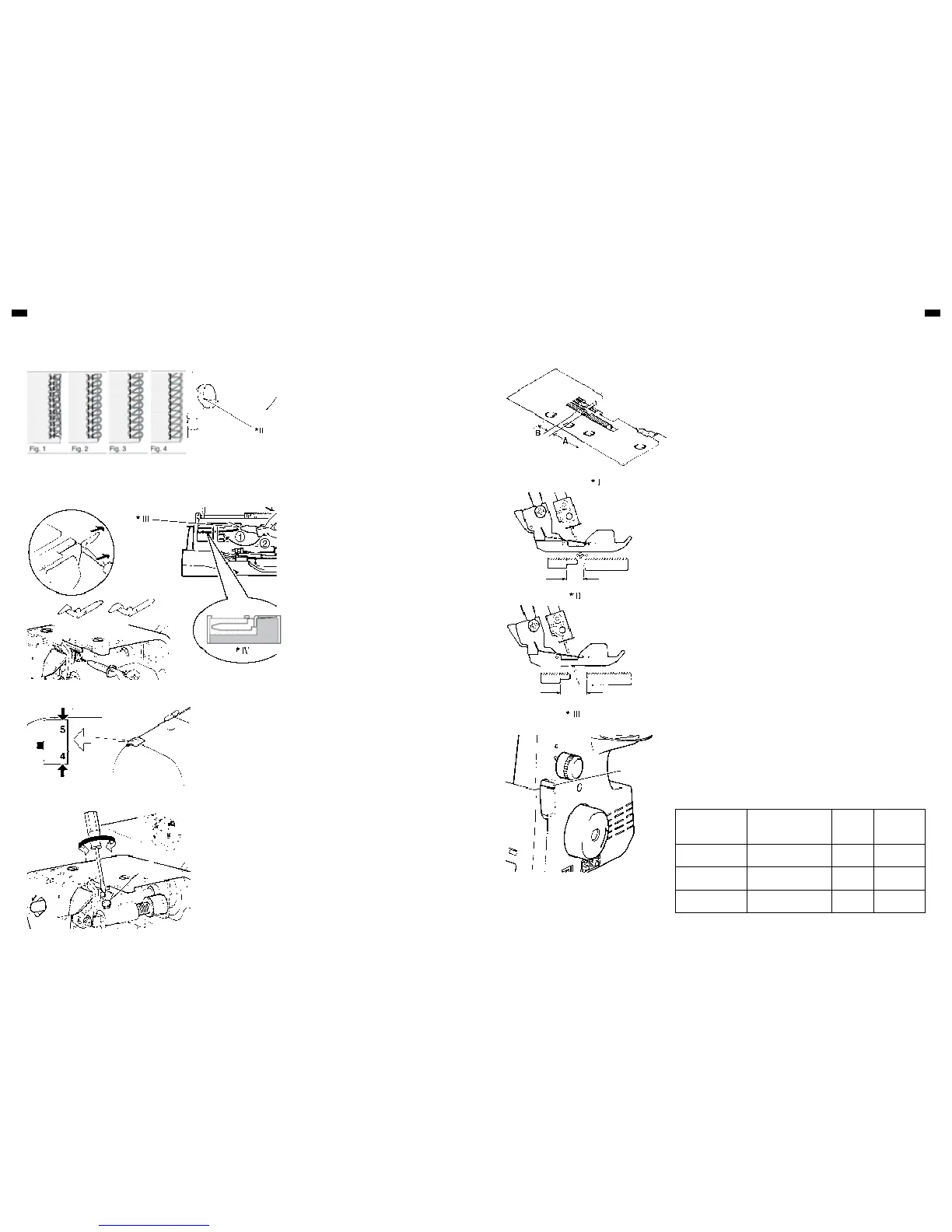

(Fig. 1)

Turn it towards “7 “ if loops hang off the edge. (Fig.

2)

Loops may hang off the edge, when you sew with

lightweight fabric using 3 threads (right needle

only), and setting cutting width dial at 4 - 5 (Fig. 3).

In such a case change the stitch finger (A) to (B) to

get neat stitching (Fig. 4).

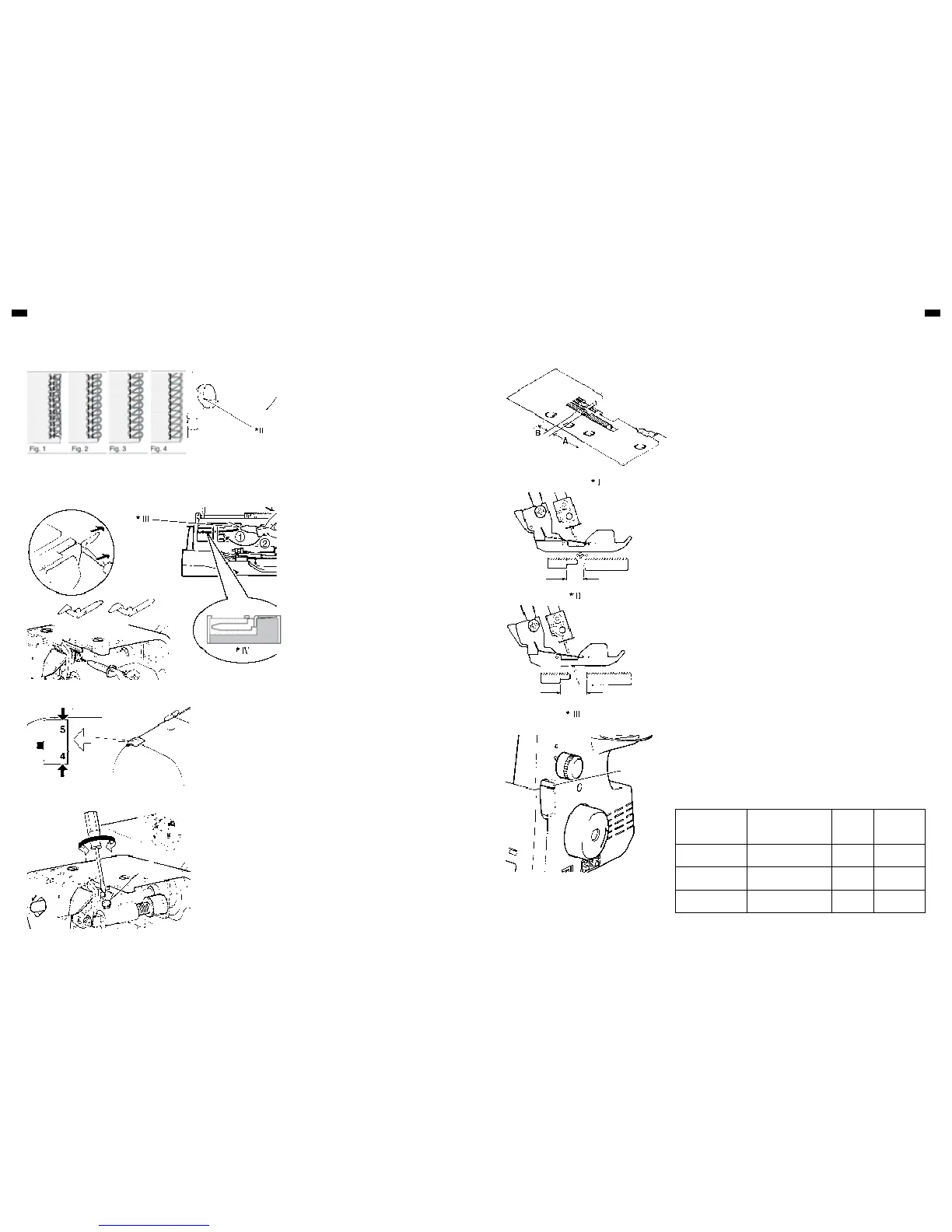

The differential feed has two independent feed dogs, one front (A) and one rear

(B).

Each feed dog has an individual feed mechanism which enables the feeding of

material at a different ratio.

DIFFERENTIAL FEEDADJUSTING OVEREDGE CUTTING WIDTH

STITCH FINGER (B)

FOOT PRESSURE REGULATOR

Presser foot pressure has been correctly set at the

factory, so you do not need to adjust it for most of

ordinary sewing. If adjustment is necessary, turn

the foot pressure regulator to higher number to

increase or to lower number to decrease pressure.

SEWING WITH EXTRA HEAVYWEIGHT FABRIC OR MULTIPLE LAYERS OF FABRIC

A wide range of fabric can be overlocked on this

machine, but it is recommended to tighten screw as

illustrated, when sewing with extra heavyweight

fabrics or mulitiple layers of fabric. Open working

table for adjustment.

Loosen the screw when sewing with light to normal

weight fabric or turning overedge cutting width dial,

or otherwise fabric may not be well cut.

The machine is set for normal weight fabrics from

the factory.

POSITIVE DIFFERENTIAL FEED

WHEN SET FOR POSITIVE DIFFERENTIAL FEED, the front feed dog (A)

makes a longer stroke than the rear feed dog (B).

This has the effect of accumulating material under the presser foot to offset the

wavering on the fabric.

NEGATIVE DIFFERENTIAL FEED

WHEN SET FOR NEGATIVE DIFFERENTIAL FEED, the front feed dog (A)

makes a shorter stroke than the rear feed dog (B).

This has the effect of stretching material under the presser foot to offset the

puckering on the fabric.

SETTING DIFFERENTIAL FEED

Set by simply moving the differential feed control lever in the direction desired

referring to the chart below.

The adjustment can be made between 0.7 (negative effect) and 2 (Positive

effect). These settings give the best ratio of feeding.

For normal sewing, the lever should be set at 1.

The lever can be reset even while sewing.

EFFECT AND

APPLICATION

TYPE OF FEEDING SETTING

FEED RATIO

REAR/FRONT

Waver-free seams,

Gathering

Positive differential feed 1-2 |-----------|----------------|

No differential feed Neutral feed 1 |--------------|-------------|

Pucker-free seams Negative differential feed 0.7-1 |-----------------|----------|

Illustration

V. Increase

VI. Decrease

VII. Tighten

VIII. Loosen

IX. Screw

Illustration

II. Overedge cutting width dial

III. Stitch finger (B)

IV. Cross section

Illustration

I. Differential feed dogs

II. Positive differential feed

III. Negative differential feed

IV. Differential feed control lever

IV

V

VII VIII

IX

VI

Loading...

Loading...