8 9

OPERATING INSTRUCTIONMACHINE OVERVIEW AND INSTALLATION

A

E

J

B

B

K

C

G

F

H

D

D

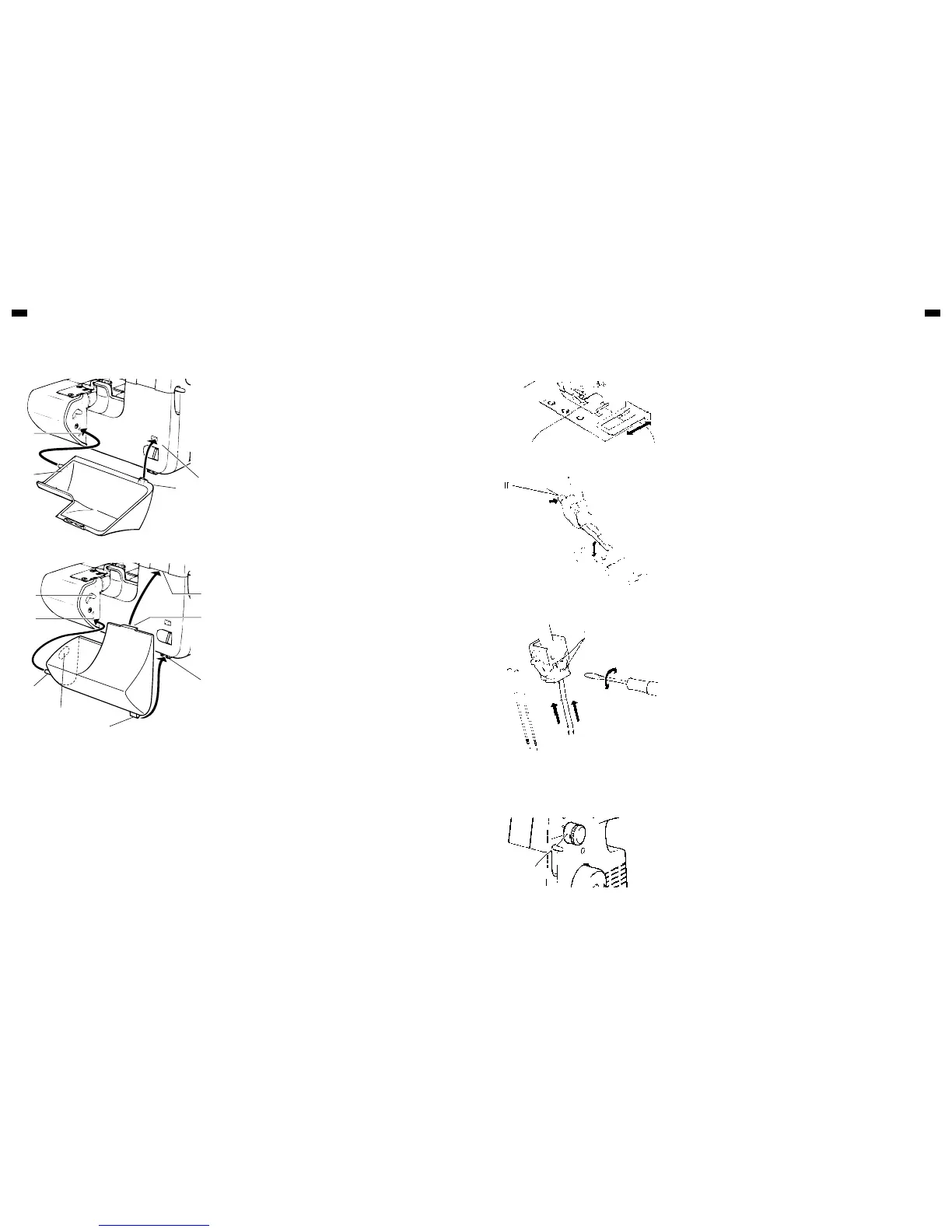

LINT TRAY

When attaching the lint tray onto the position where it may collect scraps of

fabric, insert the projection (B) into the upper hole (A) and the projection (D)

into the hole (C) at the same time.

When storing the lint tray onto the machine after completion of work,

1. Insert the projection (B) into the lower hole (E) and release lever (J) into the

hole (K) at the same time,

2. Insert the projection (D) into the hole (H) and the projection (G) into the

hole (F).

*I

*II

*III

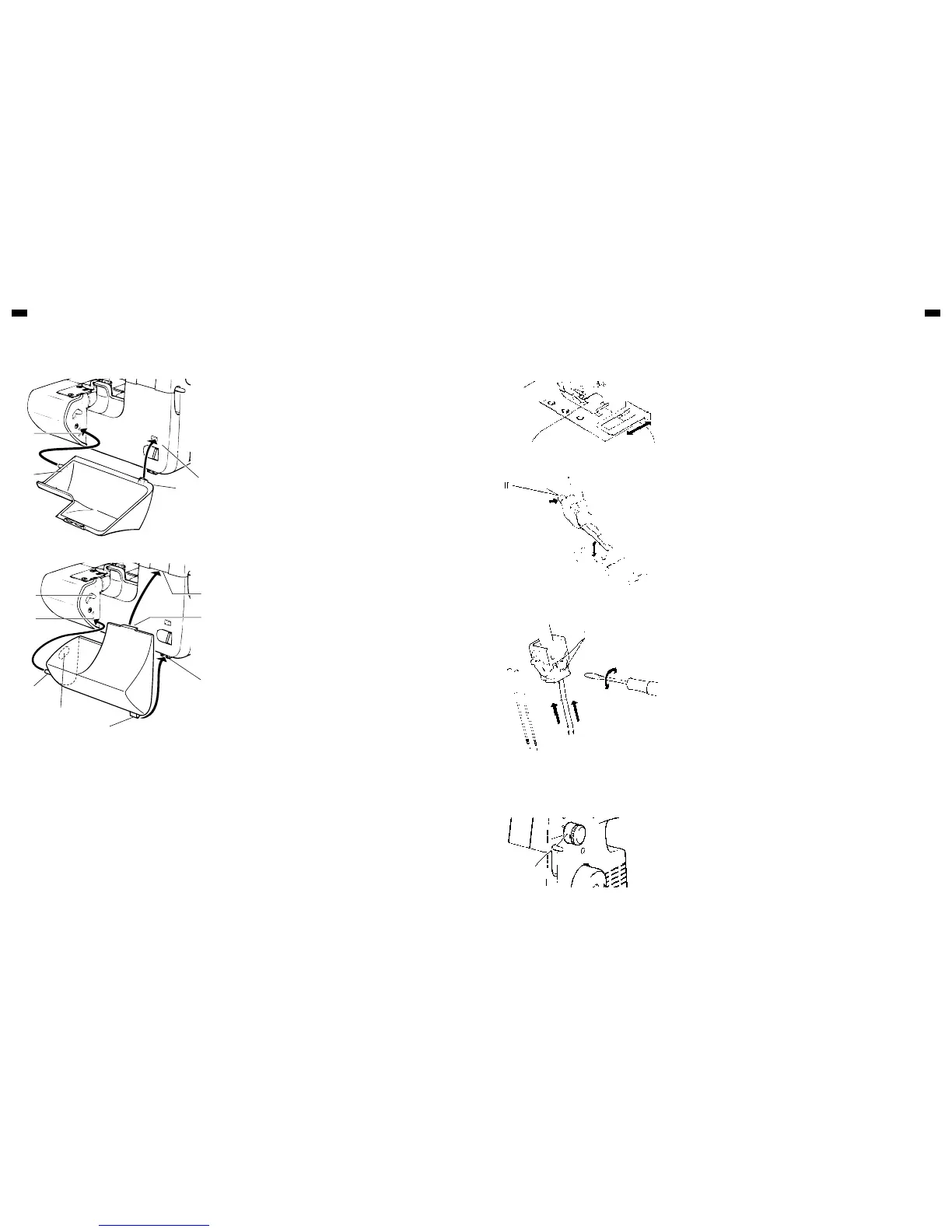

CHANGING NEEDLE

Raise needle bar to its highest point by turning hand wheel towards you, but

leave presser foot down. Loosen needle clamp screw to remove the needle,

and place new needle with Flat Side Away From You, into the needle bar as

far as it will go, and tighten screw.

CUTTING WIDTH GAUGE

When using cutting width gauge, the fabric is cut down and sewn at same

distance from the edge of fabric within the distance of the width adjuster.

CHANGING PRESSER FEET

Be sure needle is in the up position. Raise presser foot lever.

1. Push foot release lever to remove the foot.

2. Place the desired foot on the needle plate aligning needle holes.

3. Lower the presser foot lever and push foot release lever so that the foot

holder snaps on the foot.

BASIC OPERATING PROCEDURES

OPERATING INSTRUCTION

ADJUSTMENTS AND SETTINGS

STITCH LENGTH

Turn the stitch length dial until the required length is obtained.

The higher the number, the longer the stitch. This dial can adjust the stitch

length from 1 to 5 mm all so on Position P and R.

Illustration

I. Foot release lever

II. Needle clamp screw

III. Flat side away from you.

IV. Stitch length dial

IV

Loading...

Loading...