26 27

MAINTENANCEMAINTENANCE

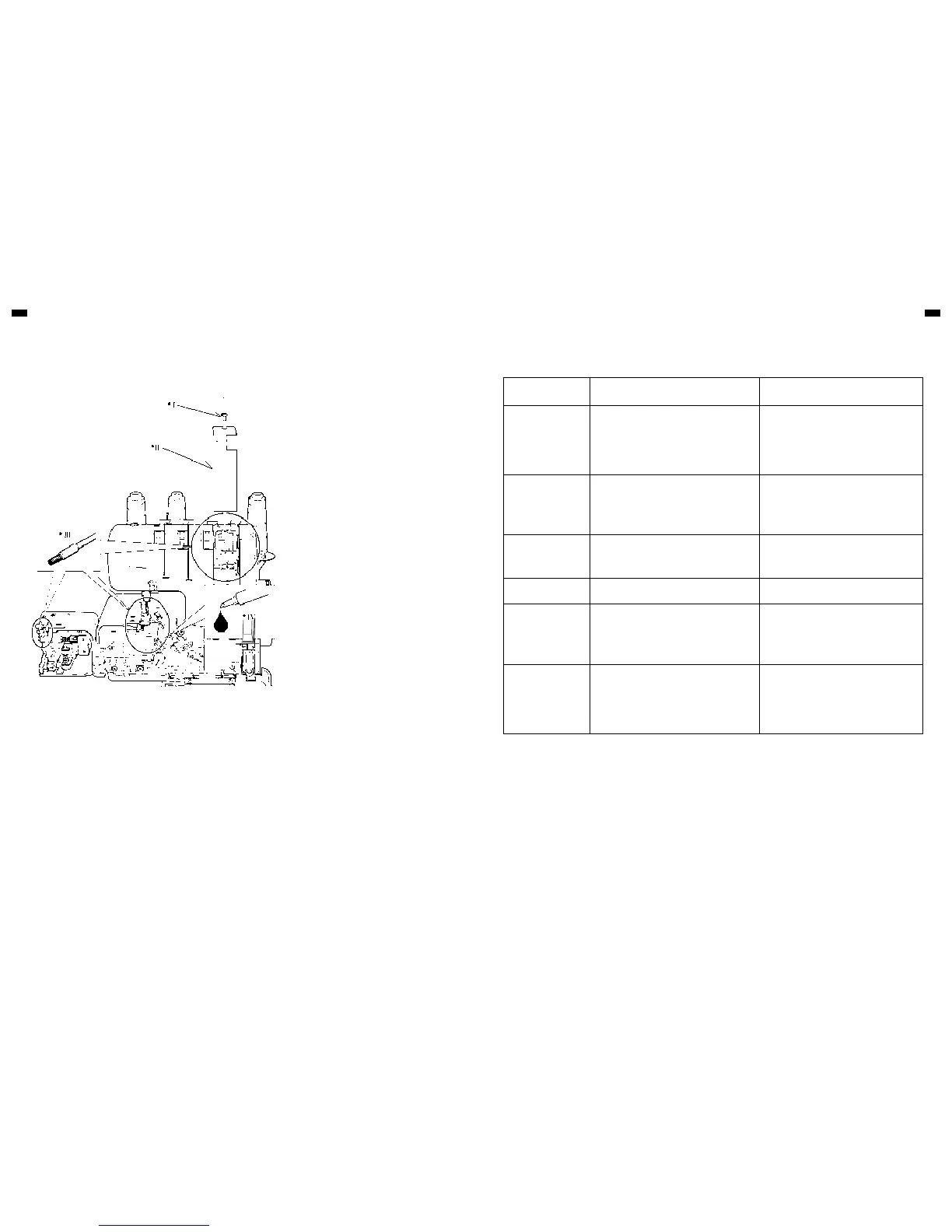

CLEANING AND LUBRICATING

To keep the machine running smoothly, keep it

clean and lubricated at all times.

FIRST DISCONNECT MACHINE FROM POWER

SUPPLY BY REMOVING PLUG FROM SOCKET-

OUTLET.

1. Open the front cover and working table. Using

the brush provided, remove dust and lint that

have accumulated.

2. Apply a few drops of oil to the points indicated

by arrows.

ALWAYS USE A GOOD QUALITY Overlock

machine OIL.

3. Remove front cover with screw driver and

remove dust and lint of inside with the brush.

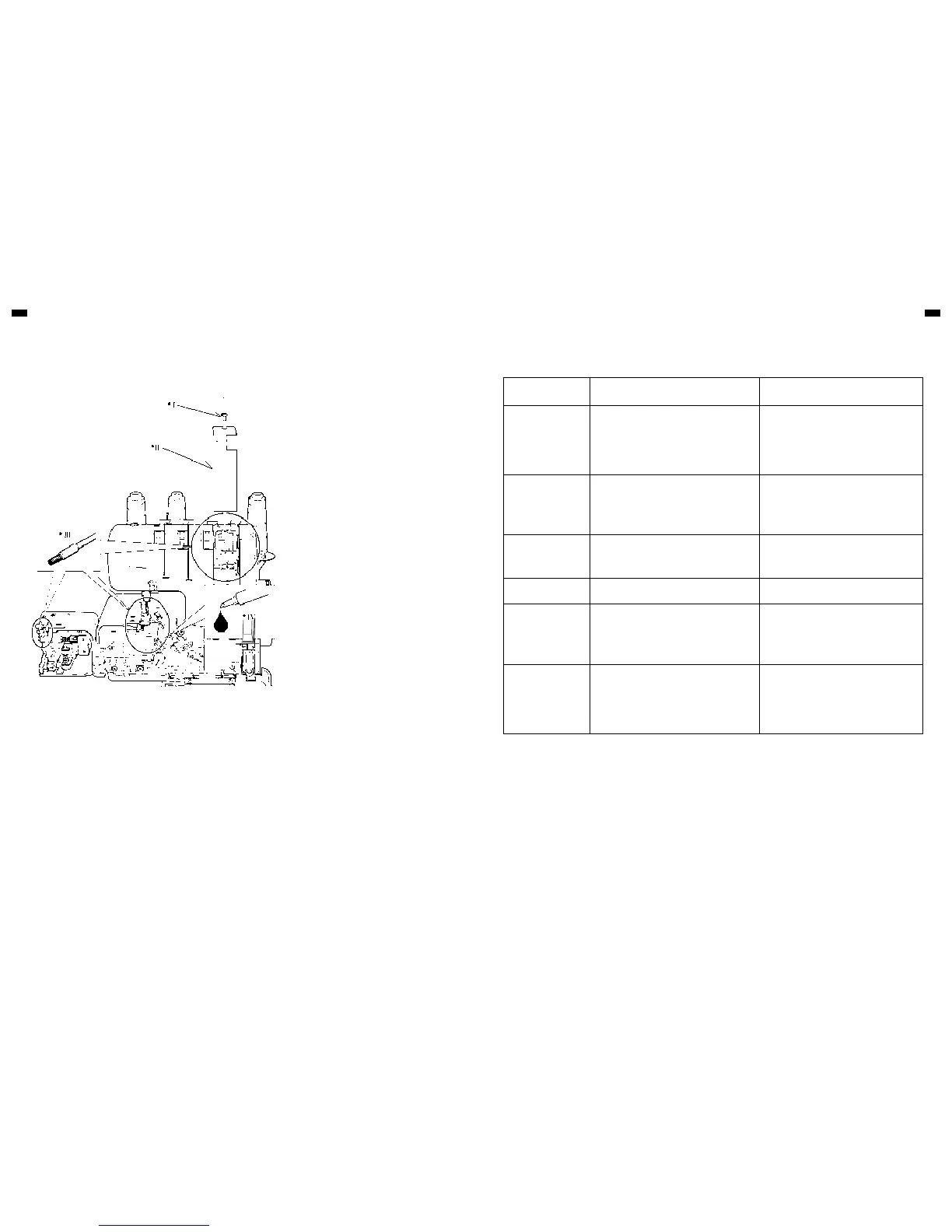

PROBLEM PROBABLE CAUSE CORRECTION

Irregular Stitches

Incorrect Thread Tension(s).

Incorrect size Needle.

Improper Threading.

Pulling Fabric.

Loose Presser Foot.

Reset Thread Tension(s).

Choose correct size Needle for Thread and

Fabric.

Re-thread Machine.

Do not pull Fabric; guide it gently.

Reset Presser Foot.

Breaking Needle

Pulling fabric.

Incorrect size Needle.

Incorrect setting of Needle.

Loose Presser Foot.

Do not pull Fabric; guide it gently.

Choose correct size Needle for Thread and

Fabric.

Reset Needle.

Reset Presser Foot.

Puckering

Incorrect Thread Tension(s).

Bent or blunt Needle.

Differential feed is set incorrectly.

Reset Thread Tension(s).

Insert new Needle.

Set it at less than 1.

Wavering Differential feed is set incorrectly. Set it at 1 or at more than 1. for knitted fabrics.

Skipping Stitches

Incorrect size Needle.

Improper Threading.

Bent or blunt Needle.

Incorrect setting of Needle.

Re-thread Machine.

Choose correct size Needle for Thread and

Fabric.

Insert new Needle.

Reset Needle.

Breaking Threads

Improper Threading.

Bent needle.

Thread Tension(s) too tight.

Incorrect setting of Needle.

Thread Spool tangled.

Thread Guide Pole not extended.

Re-thread Machine.

Insert new Needle.

Reset Thread Tension(s).

Reset Needle.

Reset Spool properly.

Fully extend Guide Pole.

TROUBLESHOOTING GUIDE

Illustration

I. Screw

II. Front cover

III. Brushing

IV. Oil

Loading...

Loading...