4

bernette SEWING MACHINE WORKBOOK

SEWING MACHINE NEEDLES

General Information

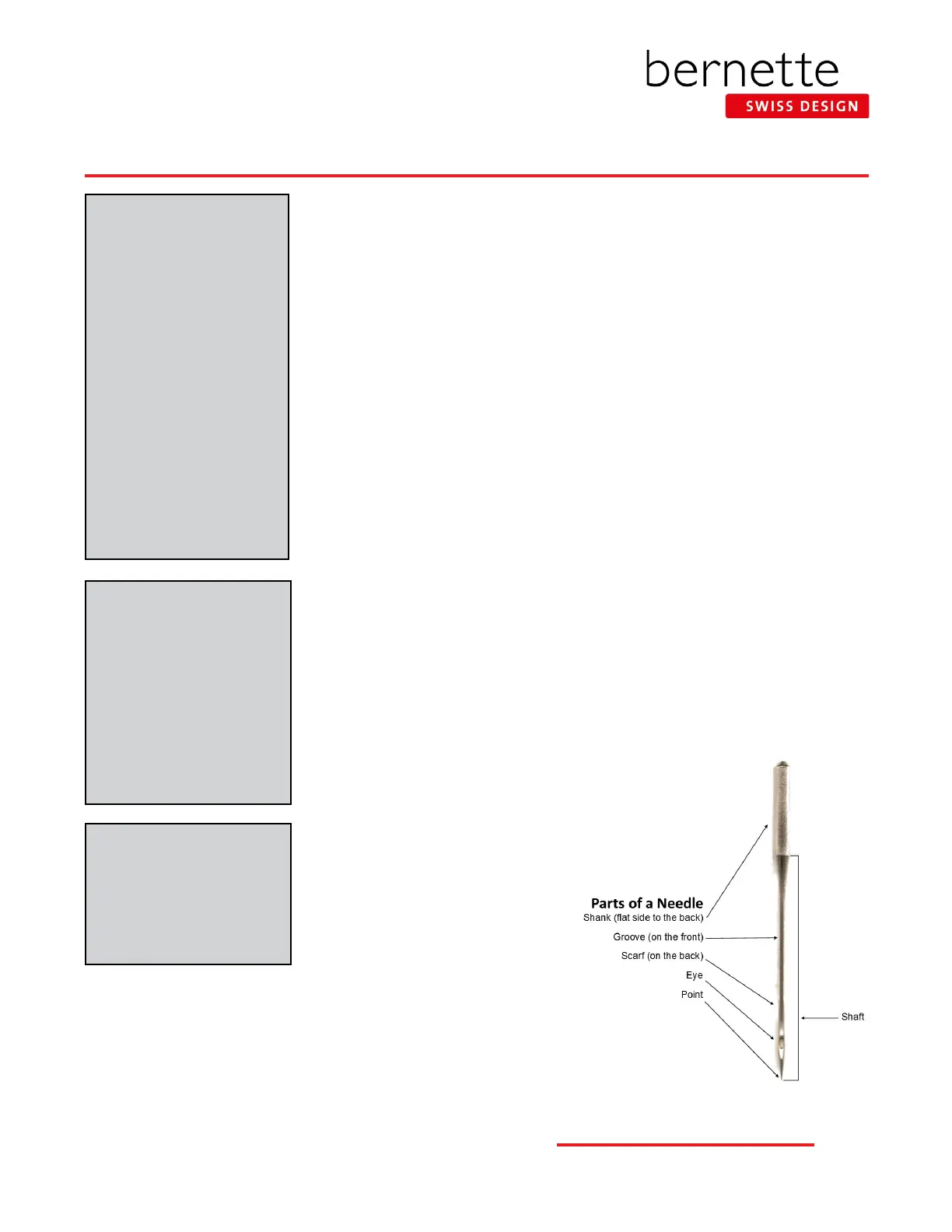

Along with thread, needles are very important to stitch formation. Many “mechanical”

problems and damage to fabrics can be traced to a bent, damaged, or incorrect size or

type needle.

When selecting the correct needle, consider the following:

• Needle system – 130/705H

• Needle point – assures proper stitch formation; avoids fabric damage

• Needle size – smaller for lightweight fabrics; larger for heavier fabrics

If the needle is:

• Too small – the thread can’t stay in the groove to form a loop to be picked up by the

hook point

• Bent – the thread loop forms too far away from hook point and the hook can’t enter

the loop to form a stitch

• Blunt – the needle won’t pierce fabric, so no thread loop forms to make a stitch

Need to Know

• Needles should be changed after every 4-6 hours of stitching. The needle is the most

inexpensive part in your sewing machine, but it is crucial for getting good results and

keeping your machine running well.

• Don’t let false economy keep you from doing what is best for your sewing projects

and your machine.

• The selected thread should t in the groove on the front of the needle. If it isn’t

protected by the groove, a needle

with a larger groove should be

used.

• Always make sure needles are fully

inserted as high as possible, with

the at side to the back.

Needle “Secret” Code

• DRI = Triple

• E = Embroidery

• J = Jeans

• L, LL, R = Leather

• M = Microtex

• MET = Metallic

• N = Topstitching/

Cordonnet

• Q = Quilting

• S = Stretch

• SUK = Fine Ball Point

• SES = Medium Ball Point

• WING = Wing

• ZWI = Double

• ZWIHO = Double Wing

Needle Size Conversion

Regardless of the system,

the greater the number,

the larger the diameter of

the needle.

European vs. Domestic

60=8 90=14

70=10 100=16

75=11 110 =18

80=12 120=19

Needle Size for Fabrics

60 – very ne batiste

70 – shirt-weight

80 – medium-weight

90 – denim and twill

100/110/120 – canvas

Loading...

Loading...