Do you have a question about the Berthoud VANTAGE E.C.TRONIC 28-30 and is the answer not in the manual?

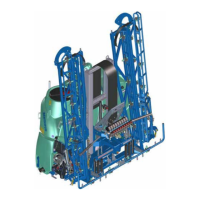

Details about the sprayer's technical specifications, including chassis, axle, brake, structure, tanks, and regulation.

Provides weight data for different VANTAGE models and boom types, essential for load planning.

Lists the external dimensions in metres for various VANTAGE models and boom configurations.

Explains the location and meaning of information found on the machine's identification nameplate.

Details adjustable and standard track widths and rim offsets for different tyre sizes.

Reports airborne noise levels emitted by the sprayer during operation.

Illustrates the location and types of safety stickers on the sprayer for user awareness.

Details the buttons and functions of the E.C.Tronic control unit for sprayer operation.

Describes the multifunction joystick for wireless control of sprayer and spraying functions.

Explains the functions of the Berlogic panel for controlling sprayer operations and settings.

Details the technical characteristics of the Omega pump used in the sprayer.

Explains the function and operation of the tracking axle system.

Describes how to transition the boom from road to field and orient it manually.

Details the operation and folding/unfolding of the manual strut.

Explains the operation of the hydraulic strut for raising or lowering the drawbar.

Describes the ribbon gauge for readable tank volume display inside the tractor cab.

Details the Nivelec unit for digital display of the tank volume.

Explains the Nivomatic unit for digital display and programming of tank fill volume.

Describes the rinsing tank's capacity and filling procedure with safety warnings.

Details the hand wash tank for hygiene and its operation with safety warnings.

Explains the procedure for draining the tank, including safety and residue management.

Describes hydraulic agitation for consistent product mixture in the tank.

Explains the function of rinsing balls for cleaning the tank.

Provides a procedure for cleaning the exterior of the sprayer and tractor.

Recommends the optimal working height for the boom to minimize drift.

Describes the folding ladder for safe access to the manhole, including safety warnings.

Details how to open and close the various doors, boxes, and the front bonnet.

Explains how to correctly adapt the transmission shaft length for safe operation.

Details how to adjust the track width for optimal alignment with the tractor.

Explains the adjustment of the service brake pressure based on load and tyre type.

Describes how to engage and disengage the sprayer's parking brake.

Explains how to adjust the drawbar position for different machine configurations.

Provides instructions for thoroughly rinsing the sprayer before its initial use.

Offers important advice for starting up and operating the sprayer safely and efficiently.

Details the steps for safely hitching the sprayer to the tractor.

Explains the procedures for filling the sprayer tank via gravity or external suction.

Describes the function and operation of the mixing hopper for powders and liquids.

Details how to use spray controls and adjust agitation levels for spraying operations.

Outlines the work sequence for triggering the dilution of residual liquid.

Provides a step-by-step guide for rinsing the machine using the DUALMATIC system.

Provides a step-by-step guide for rinsing the machine using the DUALELEC system.

Explains the procedure for performing exterior washing of the sprayer.

Details the steps for safely unhitching the sprayer from the tractor.

Offers general advice for regular cleaning, foam prevention, and end-of-season maintenance.

Explains how to clean and maintain the suction and discharge filters.

Provides instructions on how to clean clogged nozzles using a brush and water.

Lists essential checks for tyre pressure, pipes, seals, pump, and tank before the season.

A table outlining periodic maintenance tasks and their recommended frequencies.

Details the procedure for correctly overwintering the sprayer to prevent damage.

Advises on protecting the machine and boom when spraying liquid fertiliser.

Explains how to rinse, drain, and grease the boom components after use.

Emphasizes checking nut tightness on wheels, axles, and tow coupling periodically.

Provides safety precautions and steps for changing a sprayer wheel.

Details the lubrication and greasing procedures for the gearbox, pump, and various points.

A visual guide and schedule for greasing various components of the sprayer.

A diagram illustrating the E.C.Tronic hydraulic circuit.

A diagram showing the hydraulic circuit for the E.C.Tronic with Dilunet option.

A diagram illustrating the hydraulic circuit for the E.C.Tronic with Dilunet + option.

| Brand | Berthoud |

|---|---|

| Model | VANTAGE E.C.TRONIC 28-30 |

| Category | Paint Sprayer |

| Language | English |