Do you have a question about the Berthoud WIN'AIR 600 and is the answer not in the manual?

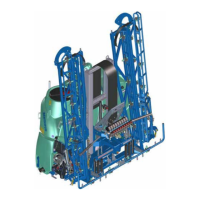

Details sprayer features including chassis, hitching, PTO, wheels, tanks, pump, and options.

Explains the sprayer's identification plate format and its components for recognition.

Provides kerb weight and gross vehicle weight data for different sprayer models.

Details atmospheric noise emission levels for the sprayer operation.

Presents diagrams and tables with overall dimensions and lift heights.

Illustrates the location of essential safety warning stickers on the sprayer unit.

Essential pre-operation checks including tank, pump oil, tyre pressure, track, and coupling.

Explains the functions of the electric control box switches for sprayer operation.

Describes the handwash and rinsing tanks, their capacities, and usage guidelines.

Details procedures for filling the main tank and incorporating liquid or powder products.

Covers valve adjustments, turbine clutching, and spraying control operations.

Explains the process for rinsing the boom and the main tank after use.

Instructions for using the optional auxiliary outlet with water from main or rinsing tanks.

Details the adjustment of the compensated return system for spray section precision.

Describes the tape gauge for monitoring the tank level from the tractor cab.

Explains the optional electric gauge for tank level monitoring.

Instructions on how to change the position of the sprayer's support leg.

Details the use and removal of the optional jockey wheel for easier movement.

Details the running board for safe access and its storage during treatment.

Explains how to raise or lower the sprayer boom using the hydraulic system.

Highlights benefits of regular cleaning for sprayer longevity and performance.

Lists essential checks before the season, including filters, leaks, and flow rate.

Provides instructions on how to protect the sprayer from frost damage during storage.

Emphasizes regular nut tightness checks and provides specific torque values.

Details the procedure for cleaning the suction and delivery filters.

Covers oil checks, draining, and valve inspection for APS 61 and APS 96 pumps.

Explains how to check and adjust the fan belt tension for optimal operation.

Outlines lubrication intervals and points for the pump, transmission, and clutch.

Diagram and itemized description of the standard spraying circuit components.

Diagram and itemized description of the spraying circuit with the flowmeter option.

Diagram and itemized description for sprayer with can rinsing and auxiliary outlet options.

Diagram and itemized description of the spraying circuit with the incorporation option.

Diagram and itemized description for sprayer with can rinsing and incorporation hopper options.

| Brand | Berthoud |

|---|---|

| Model | WIN'AIR 600 |

| Category | Paint Sprayer |

| Language | English |

Loading...

Loading...