4

1.1. TECHNICAL SPECIFICATIONS

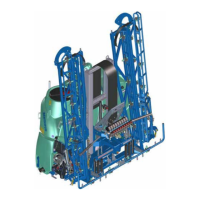

WIN'AIR 600/800/1000/1500 -

Trailed pneumatic sprayer.

- CHASSIS protected by U.H.R. polyester paint with

retractable running board.

- HITCHING:

• Hitching yoke with length adjustable drawbar.

• Support leg with wheel.

- PTO SHAFT.

- Adjustable track AXLE: made up of two sliding half

axles. Overall width: see tables, page 6.

- WHEELS:

Type of tire

WIN'AIR

600

WIN'AIR

800

WIN'AIR

1000

WIN'AIR

1500

165 R13 Standard

185 R14 Option Standard

215/75 R15 Option Option Standard

235/80 R15 Option Option Standard

10,0/75 x 15,3 Option Option Option

31/15,5 - 15 Option Option Option

- VENTILATION:

• Polyethylene ventilation case with built-in air fl ow

by 4 upper calibrated outlets.

• SPEEDAIR ventilation:

- Suction type ventilation on the front of the cell

provided by a 16-vane propeller (dia. 560 mm)

with closed centre driven by a Poly V-belt. Outside

clutch release, at rear of cell, by indexed dog

teeth.

- Maximum absorbed power: 34 HP.

• SUPAIR ventilation:

- Suction type ventilation on the front of the cell

provided by a 20-vane propeller (dia. 630 mm)

with closed centre driven by a Poly V-belt. Outside

clutch release, at rear of cell, by indexed dog

teeth.

- Maximum absorbed power: 40 HP.

- TANKS:

• High density polyethylene MAIN TANK with

diamond-shaped bottom:

- Nominal capacity 600, 800, 1,000 or 1,500 litres.

- Wide fi lling orifi ce with swing lid.

- Drain valve.

• Integrated RINSING TANK, made of high density

polyethylene, 60, 100 or 200 litres capacity

according to the sprayer capacity.

• Integrated HANDWASH TANK, made of high

density polyethylene, 16 litres capacity.

- Float GAUGE visible over 360°.

- PUMP APS 61 (WIN'AIR 600) or APS 96

(WIN'AIR 800, 1000, 1500).

- FILLING AND FILTRATION:

• Incorporation of powder by the manhole of the

main tank.

• Filtration:

- Filling fi lter (sieve, 8/10 mesh).

- Suction fi lter (vannofi lter, 6/10 mesh).

- Centralized for delivery fi lter (fi lter, 4/10 mesh).

- Hydraulic STIRRING by independent high pressure

circuit (hydro-injector). Valve to shut off stirring at end

of tank.

- VALVES BLOCK:

• BERLOGIC: manually controlled valve block with

identifi cation of different functions

.

- DPM REGULATION (fl ow rate proportional to engine

speed) with manual valves providing a constant

volume/ha independent of the advance speed of the

tractor (for the selected gear ratio).

- CONTROL of spraying in cab by 2 electric fl ap valves,

2 sections.

Electric power cut-out on the control box in cab.

- Glycerine PRESSURE GAUGE, 0/25 bar, diameter

100 mm, 0/6 bar dilated scale.

- LIGHTS AND SIGNS in compliance with the highway

code.

- EQUIPMENT:

• VITIFIRST boom.

• VITISET boom.

• Hydraulic VITIFLEX boom.

• AB Most boom with manual spreading.

• Telescopic AB Most boom.

- OPTIONS:

• Articulated hitch with homokinetic joint on sprayer

side.

• Jockey wheel.

• Homokinetic universal joint transmission.

• Single Russian universal joint transmission.

• Independent incorporation hopper to be connected

to the auxiliary outlet.

• Storable incorporation hopper (1,500 litres).

• Powder incorporator in the sieve of the main tank.

• Auxiliary outlet.

• Can rinsing in the sieve of the main tank.

• Tape gauge or NIVELEC gauge (E.C.Control).

• DP Elec for the electric control of the regulating

valve in cab.

Loading...

Loading...