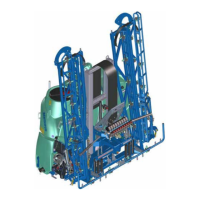

82527 Vantage 35

5.4 CHECKS BEFORE THE SPRAYING SEASON

Check the tyre pressures:

Check the tightness of the wheel pins.

Filters: Make sure of the good condition and

cleanliness of the suction and discharge lters.

TYPE OF

TYRE

PRESSURE IN BARS

KLEBER MICHELIN ALLIANCE

230/95 R44 3.6 4.3 4.3

230/95 R48 3.6 4.3 4.3

270/95 R48 4 4.3 4.3

300/95 R46 4.3 4.3 4.3

340/85 R38 1.9 1.9 1.9

380/85 R46 - - 4.2

420/85 R38 2 1.9 1.9

460/85 R38 2 1.9 1.9

Pipes: Search for any leaks and check the bends in

the pipes.

Seals and connectors: Check the tightness of the

nuts on the connections and change the seals if

necessary.

Pump, gearbox, angle transmission: Check the

levels of oil.

Nozzles: Change the nozzles once a year or when

their ow becomes 10% to 15% greater than their

initial ow. For this, use the FLOW TEST BERTHOUD

reference 765.241 or the FLOW COMPARATOR

BERTHOUD reference 778.887.

Tank: Check that there are no foreign bodies in the

tank.

5.5 PERIODIC MAINTENANCE TABLE

5.3 CLOGGED NOZZLES

Clean and rinse the clogged nozzles using a brush

and water.

For this, use the key-brush reference BERTHOUD

779.354.

WARNING:

Never blow into a nozzle.

Inspection points

At each

treatment

Monthly

After

overwintering

Before

overwintering

Rinsing the tank

x x

Rinsing the spray circuit

x x x

Cleaning the suction lter

x x

Cleaning the discharge lter(s)

x x

Cleaning the nozzles

x

Checking the road signalling

x

Water-repellent product on the electrical sockets

x x x

Cleaning and greasing the transmissions (universal joint)

x (or maxi 50h) x x

Cleaning and checking the owmeter

x x x

Condition of the cables

x x

Condition of the safety components

x x

Alignment of the nozzle holders and the nozzles

x x

Alignment of the arms of the boom

x x

Greasing the friction parts

x x

Greasing the articulation points

x

Level of oil in the pump

x

Tighten the wheel nuts

x

Check the pressure of the tyres

x

Clean the anti-drips

x

External cleaning

x

Check the ow of the nozzles

x

Check the anti-drips

x

Drain the pump

x

Drain the gearbox

x (or maxi 200h)

Check the pressure of the nitrogen ball (50 bars)

X

Loading...

Loading...