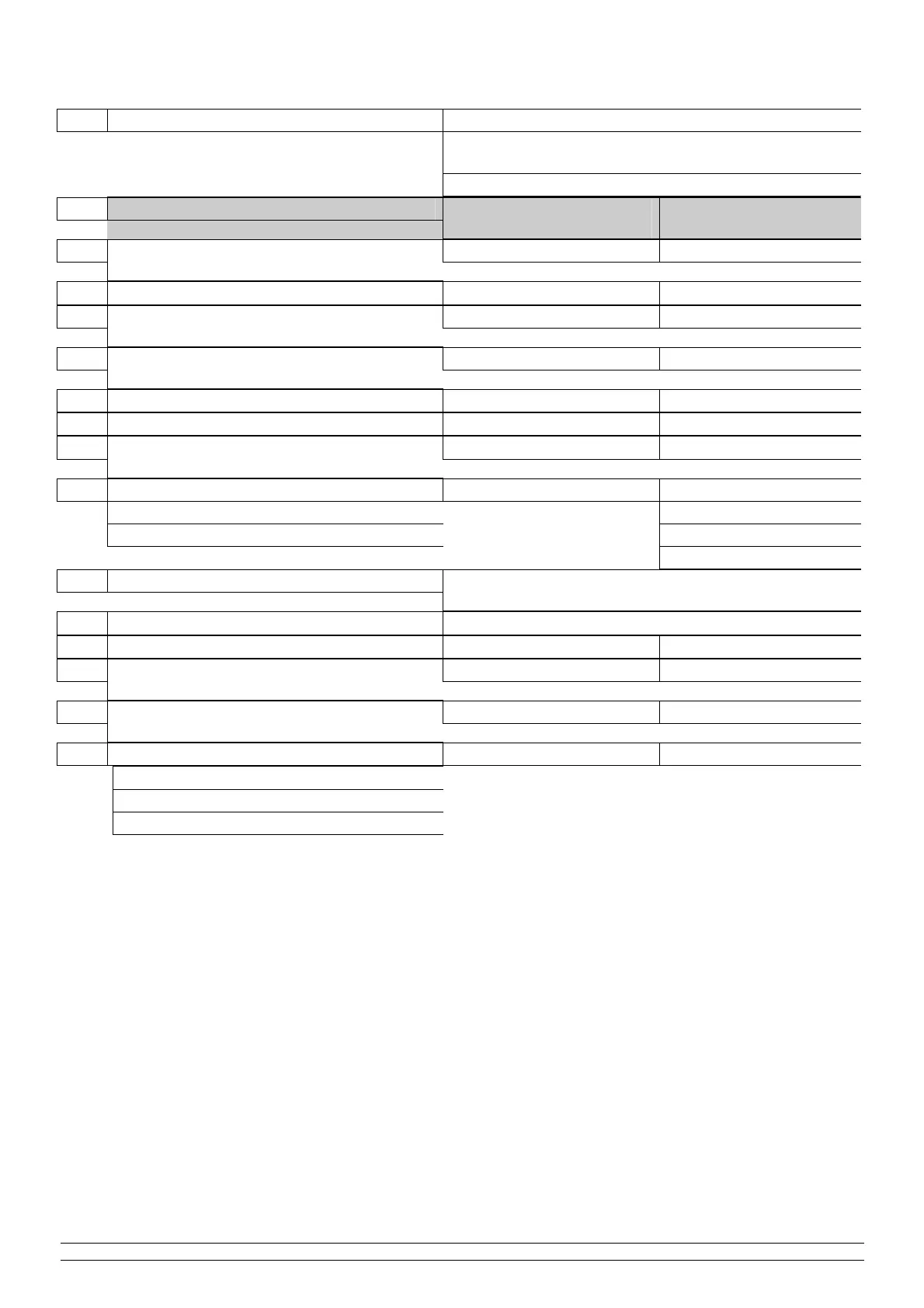

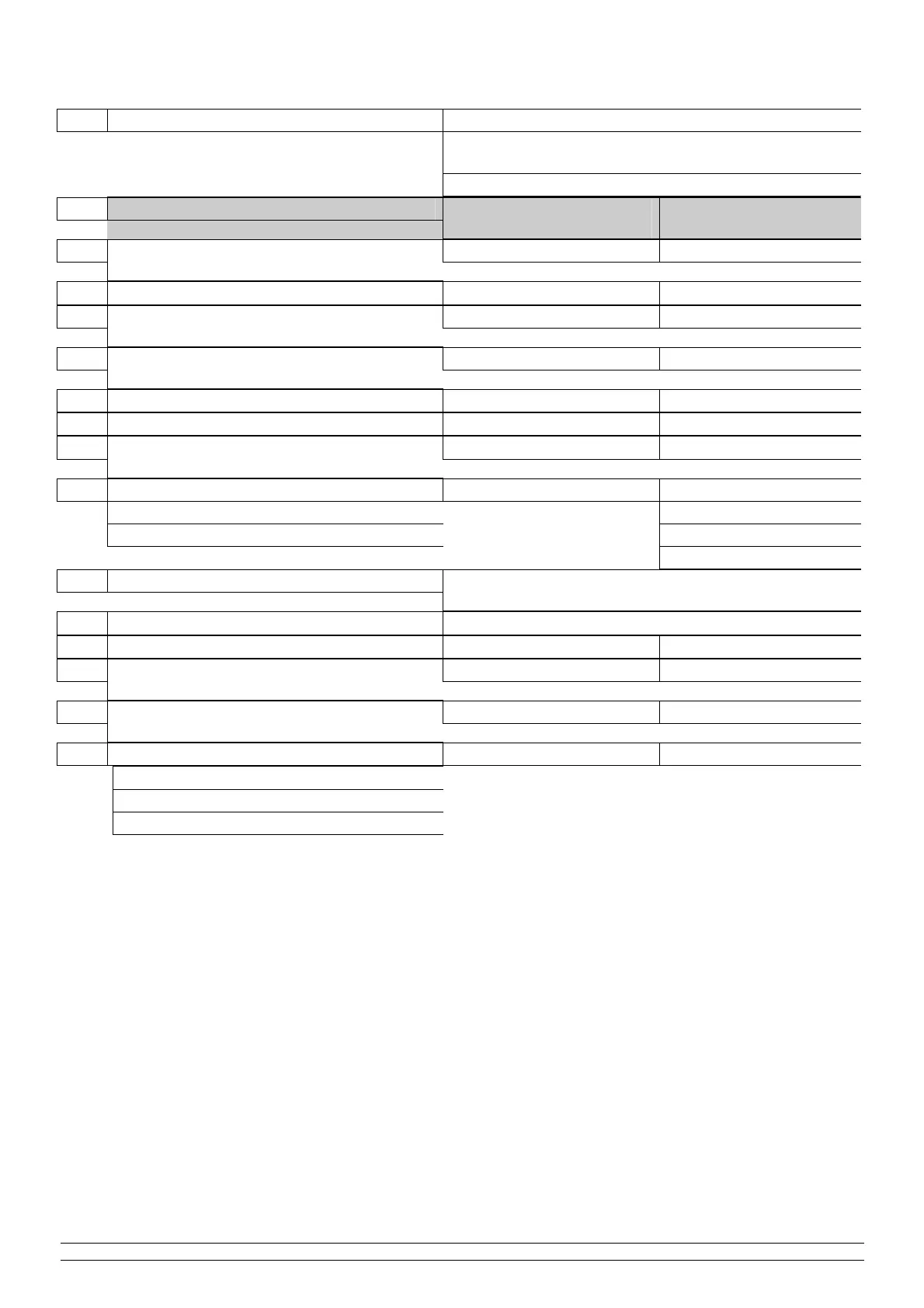

MARQUE, MODELES ET BREVETS DEPOSES - PRODUITS EXCLUSIFS

RECOMMENDED INSPECTIONS AND PREVENTIVE MAINTENANCE

0 CHANGING UV LAMPS AT THE END OF THEIR LIFE SPAN:

- EITHER DISPLAY ON THE MILLÉNIUM III MONITOR:

UV INTENSITY <50%

- OR COMBINED CHLORINE RATE IN THE BASIN

OPERATIONS ON EACH UV LAMP

CHANGEOVER

AT LEAST ONCE PER

YEAR

CHECKING THE GENERAL STATE OF THE UV

REACTOR

1 REPLACEMENT OF QUAD RING SEALS COMPULSORY COMPULSORY

2 CHECKING THE PRESENCE OF QUARTZ

SHEATH TEFLON SHIMS

COMPULSORY

3 CLEANING OR REPLACING THE QUARTZ

SHEATH

COMPULSORY

4 REPLACING THE CLEANING WIPERS RECOMMENDED

5 CLEANING THE UV SENSOR COMPULSORY COMPULSORY

6 CHECK THE OPERATION OF THE

FLOWMETER

COMPULSORY

7 CHECK THE OPERATION OF VENTILATORS:

- CLEANING GRILLS

- FILTER REPLACEMENT (IF APPLICABLE)

RECOMMENDED

COMPULSORY

8 UV SENSOR CALIBRATION ONLY NEW LAMPS, QUARTZ SHEATH CLEAN OR NEW, UV

SENSOR CLEANED

9 PNEUMATIC SILENCER REPLACEMENT ONLY IN THE EVENT OF CORROSION

10 CHECK THE EARTHING OF THE REACTOR

11 CHECK THE OPERATION OF THE

THERMOSTAT IN THE ELECTRICAL CABINET

RECOMMENDED

12 CHECK THE OPERATION OF THE CIRCUIT

BREAKER

RECOMMENDED

13 CHECK TIGHTENING:

- OF TERMINAL BLOCKS IN THE CABINET

- OF CONNECTORS

- OF UV LAMP CONNECTIONS

RECOMMENDED

Loading...

Loading...