16

7.7 Powder fi lling

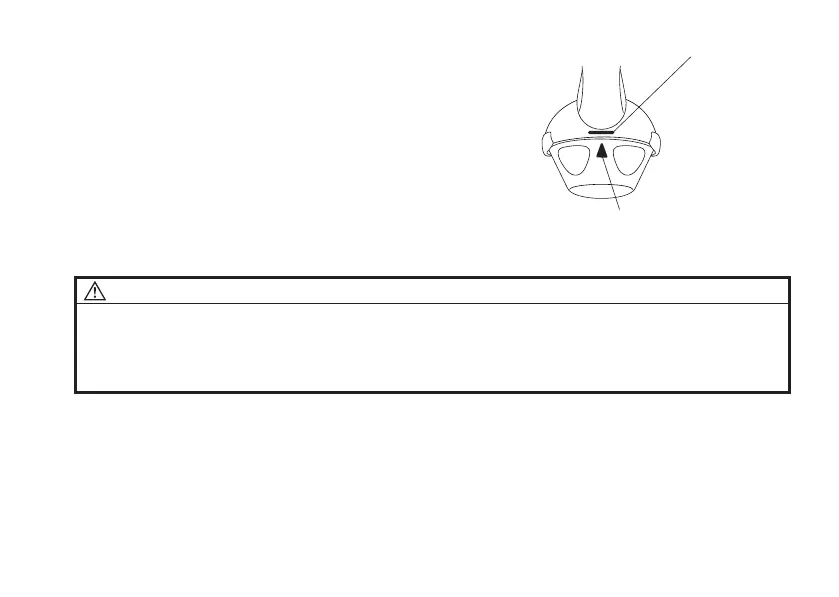

1) Remove polisher from the turbine hose before refi lling

with powder.

2) Detach the powder cap by turning in the direction of the

arrow in the illustration above.

3) Confi rm the powder stirring cap is attached in place.

4) If water, oil, or powder remains inside of powder chamber

or powder cap, remove it with a dry cloth.

5) Fill sodium hydrogen carbonate powder not exceeding 15g

into the powder cap.

* The powder must be placed into the powder

cap. Take care not to spill the powder over the

thread of the powder cap. If the powder is spilt

over the thread, wipe it off with a dry cloth.

Filling too much powder will make the powder

adhere to the powder seal and cause

premature wear of the powder seal or

incomplete sealing.

6) Hold the chamber unit downward and the powder cap

upward as shown in the illustration. Turn the powder cap

in the direction of the arrow until it stops.

Remove water, oil, and powder.

Fill the powder into

the powder cap.

Confirm the powder

stirring cap is

attached in place.

16

7.7 Powder fi lling

1) Remove polisher from the turbine hose before refi lling

with powder.

2) Detach the powder cap by turning in the direction of the

arrow in the illustration above.

3) Confi rm the powder stirring cap is attached in place.

4) If water, oil, or powder remains inside of powder chamber

or powder cap, remove it with a dry cloth.

5) Fill sodium hydrogen carbonate powder not exceeding 15g

into the powder cap.

* The powder must be placed into the powder

cap. Take care not to spill the powder over the

thread of the powder cap. If the powder is spilt

over the thread, wipe it off with a dry cloth.

Filling too much powder will make the powder

adhere to the powder seal and cause

premature wear of the powder seal or

incomplete sealing.

6) Hold the chamber unit downward and the powder cap

upward as shown in the illustration. Turn the powder cap

in the direction of the arrow until it stops.

Remove water, oil, and powder.

Fill the powder into

the powder cap.

Confirm the powder

stirring cap is

attached in place.

17

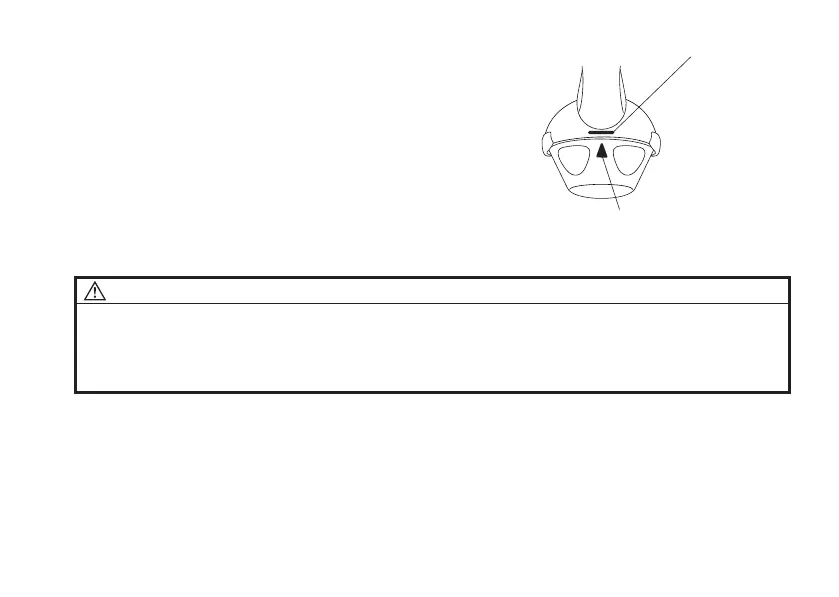

7) Confi rm the powder cap is fi rmly attached within the

range of the mounting position mark. If the triangle

symbol on the powder cap lies outside of the mounting

position mark, replace your powder seal with a new one

according to “10.4 Replacement of powder seal”.

CONTRAINDICATION AND RESTRICTION

1) Use sodium hydrogen carbonate powder for dental prophylaxis only. Other powder (for example, alumina powder) will cause

a decrease in cleaning effi ciency, powder clogging, or damage to the polisher.

2) Do not reuse the powder.

3) The powder must be fi lled into the powder cap. Filling into the chamber unit may cause a premature wear of the screw

threads and insuffi cient sealing and powder scattering.

Triangle symbol

17

7) Confi rm the powder cap is fi rmly attached within the

range of the mounting position mark. If the triangle

symbol on the powder cap lies outside of the mounting

position mark, replace your powder seal with a new one

according to “10.4 Replacement of powder seal”.

CONTRAINDICATION AND RESTRICTION

1) Use sodium hydrogen carbonate powder for dental prophylaxis only. Other powder (for example, alumina powder) will cause

a decrease in cleaning effi ciency, powder clogging, or damage to the polisher.

2) Do not reuse the powder.

3) The powder must be fi lled into the powder cap. Filling into the chamber unit may cause a premature wear of the screw

threads and insuffi cient sealing and powder scattering.

Triangle symbol

Loading...

Loading...